Hello all together,

I have read a lot here in the forum during the construction of the MPCNC and now wanted to briefly share my experiences with you. Thanks for the good instructions and ideas here in this forum. I’m a mechanical engineer who has a passion for traditional woodworking and mainly building furniture for my family :). And to extend my possibilities (building tools for example) I starting building the MPCNC.

My MPCNC had to meet the following requirements. These were:

- It must be quiet to keep the peace with the neighbors.

- Mechanics and electronics must be enclosed, so that my little son, when he can walk, does not run the risk of reaching into something rotating or live.

- It has to be compact to not steal any precious space in my small garage shop

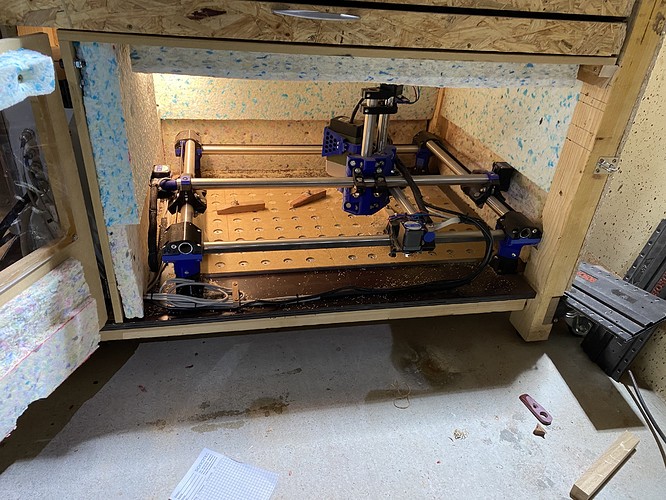

I printed the parts in PETG and decided to house it under my workbench meant for all the metal work. The result can be seen here:

It is quite small and indeed it has only a work area of 35x45cm. But which is fine for me (yes, I know I swapped one of the axis in a wrong orientation. I’ll get to that. I promise).

As a spindle I used a Proxxon UF/E which only has 250W but runs very stable (and quite quietly). The RPM reaches from 10.000 to 30.000. I was lucky and got it for 200€ (which is not quite the intended low price for the build, but the extra quietness was worth it). It weighs around 800g. I don’t know if those are available outside EU.

As you can see in the pictures I insulated everything with heavy foam (also from the underside). Mainly for noise reduction.

On the electronics site I use a Raspberry - Arduino - CNC Shield combination, which I had at hand from a past project. As a monitor I use a 7’’ touch screen, which works surprisingly well, because most of the work I do remote from my workstation.

Overall I can say that it was a total success. While at work and cutting it is quieter than those fully automatic coffee machines. I’m also quite happy of how it blends with my workshop, because I built it under one of my workbenches. First project was a little whale for my keychain. But the first real handtool (a handplane) is already in work. You can see it on my carpenters bench at the picture below.

Thanks again and I hope I was able to inspire some of you that it is possible to make those things quiet, even without watercooled spindles ;).

Have a great rest of the week.

BR

Volker

P.S.: I was able to determine a repeatability of about 0.08mm using a dial gauge.

P.P.S. Apparently I wasn’t able to upload multiple pictures, because I’m a new user. I try to post the below