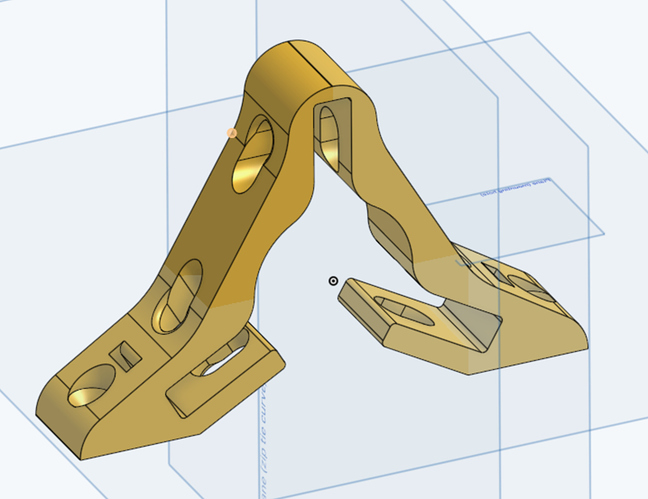

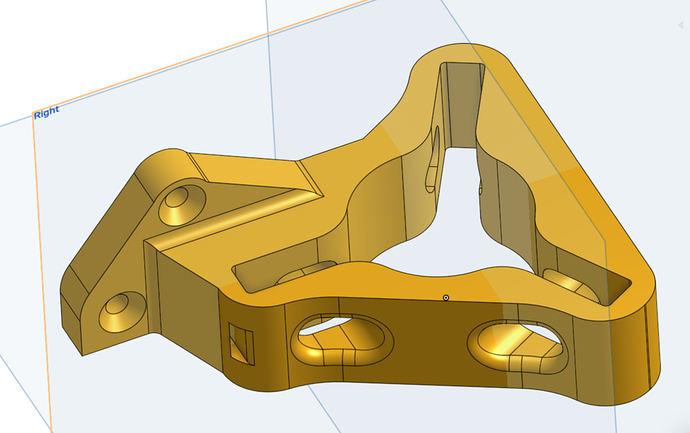

I have made an adjustable bearing block:

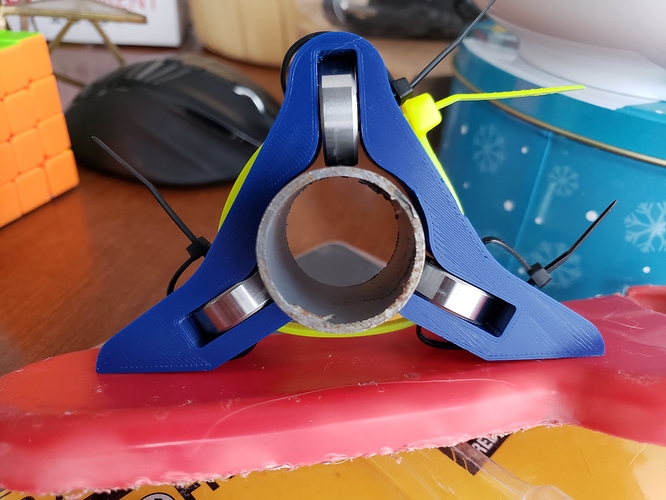

For the picture I used a small section of 1" EMT (1.163" OD), and am very pleased with the result. The block is designed to use from 3/4" EMT (.922" OD) to 1.25" standard tube.

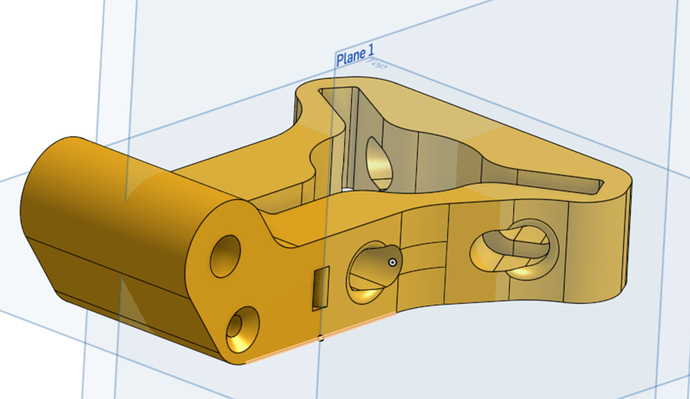

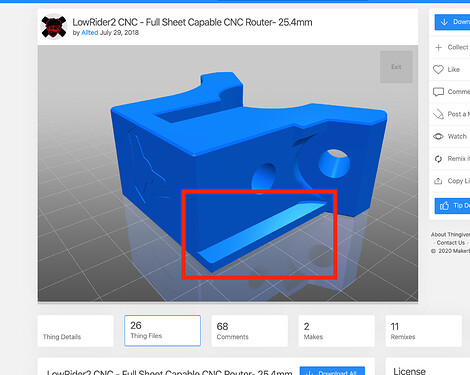

The following screenshot shows the adjustment slots a little more clearly:

Bearing axle

The axle is just 5/16" brass tubing. Any other metal (aluminum/copper/steel) would work just as well. I think that even a plastic might work. The essential bit is that it’s hollow, so you can pass the zip tie through the center.

I don’t have my kitchen scales with me, so I can’t compare weight, but it’s three 5/16" nuts and bolts lighter. That’s a significant difference, esp. if multiplied by the 8 bearing blocks throughout.

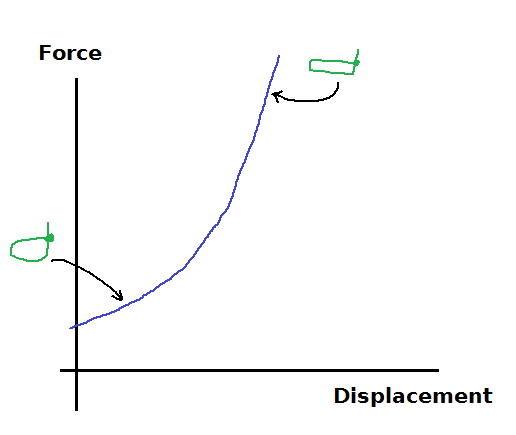

Adjusting the size

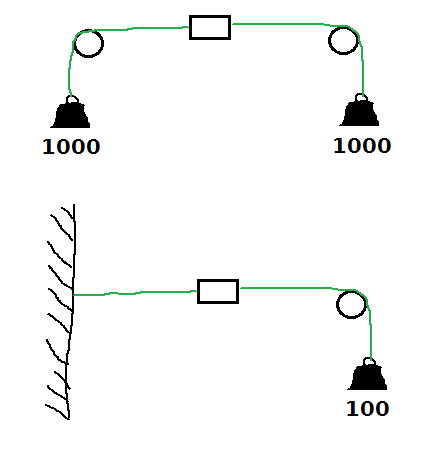

The zip-ties are the adjustment mechanism. By tightening the black zip ties, the axle moves back, enlarging the hole. By tightening the white zip ties, the axle moves forward, narrowing the hole.

What I like about zip-ties:

- Cheap

- Readily available

- Lightweight

- Easy to precisely tighten (listen to the number of clicks)

What I don’t like about zip-ties:

- Difficult to ensure uniformity (placement of the zip-tie head matters a lot for overall tension)

- Stretchy plastic in a critical dimensional tolerance pathway

- Impossible to loosen.

It’s not clear yet if the zip tie approach is the best. However, I believe that sufficiently tightened there will be less deflection than the original design, which has a cantilevered axle.

- If zip ties don’t work, it could also be done with seizing wire. Just as cheap, and absolutely impossible to stretch with cutting loads. However, it’s fiddlier to apply and adjust.

- Instead of using zip ties to support the tubes against outward forces, shims could be placed in the slot. The disadvantage of shims is that the provide less adjustability, but that’s arguably not that much of an issue since the blocks should never need to be adjusted once the tubing is purchased.

CAD model

Here is the OnShape file if you’d like to print one or otherwise play around.

Thoughts?