I’ve started building my mpcnc here in Florida. Hadn’t been to a home depot in a while, as work has kept me busy. What is with the wood prices all of a sudden…? (Rhetorical question) I was planning on building a table and basically a insulated enclosure around it. Call me crazy, I’m not paying almost $10 for a 2x4… So, for a temporary table I found a solid wood dining table on Craigslist for $40. After screwing it together so it can’t open for leaves anymore, I have a very solid table for my machine. Now, I have to widen one side by two inches, which I have the material to do. The problem I’ve run into is the spoilboard. I can’t cut out the table top to have it flush or risk weakening my table structure. Is there any reason I can’t just make the legs 3/4" taller so I don’t lose any of my z distance?

Not a problem at all

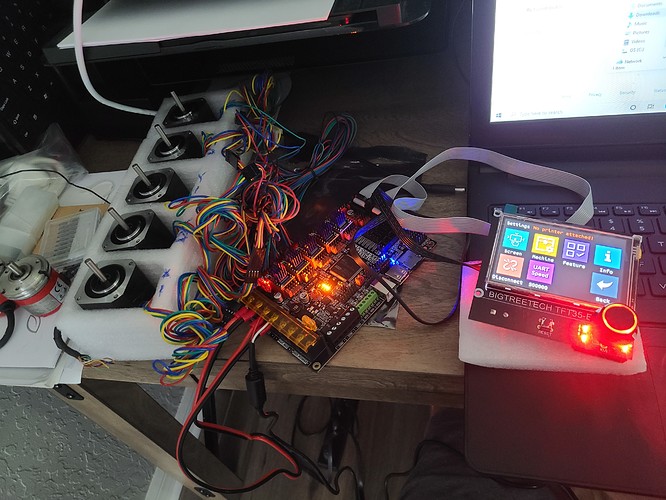

Well, life has a way of getting in the way of getting things done. But, while I’m home recovering from a bad run in with covid, I’ve made some progress with the electronics. Everything works and ready to go on the new build. It’s just too damn hot to go in the garage and finish the build while on oxygen. Really looking forward to drawing a crown soon!

Just need to set up endstops for homing so I start from a known location every time. Will install locating fence to line up material on x and y origin as I use standard size material.

Take care of yourself above everything else.

Progress is progress, the machine as a whole takes a good bit of work and time to fully put together, so there is no need to rush.

I’m looking forward to seeing your working MPCNC for sure, but take as much time as you need

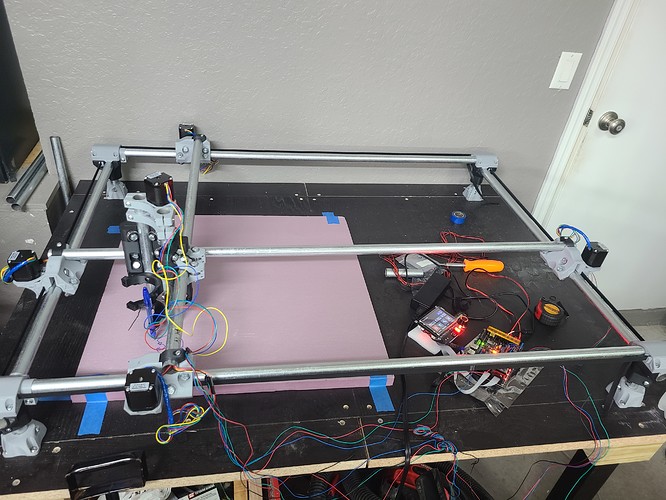

I’ve been putting together all the sub assemblies each night and finally made some progress. My wife went into the office today leaving me unsupervised… lol. Cut my rails previously. Started putting everything together. Thankfully, it was a rainy day so temperatures in the garage weren’t bad. Just had to keep my oxygen tubing out of the way… have to drill the z axis tubes and can finish that assembly. Getting close!!!

The pop up storms lately have cooled it off a bit.

Where are you located Matt? Love the Craiglist idea for wood!

I’m in odessa FL. Went to the local box stores and refused to pay the insane $10+ per 2x4. As a temporary table, I found an old solid wood dining table on Craigslist for $40. After screwing it together, it is so solid that it will be the permanent table. The leaves that came with the table were used to widen both sides by three inches to allow for clearance to add an enclosure around it in the future. After getting the mpcnc dialed in, an enclosure will be added to help dampen the noise.

Great idea. I used a pair of old kitchen cabinets as the base. Threw some casters underneath to roll it around the shop. Had some scrap 3/4 plywood for the top and 1/2 for the walls. Found some old particle board shelves being thrown away for the spoil board. I keep 1 drawer pulled out for the laptop tray. I don’t know why you would not recycle stuff for a project like this?

I am in Orlando if you ever need anything.

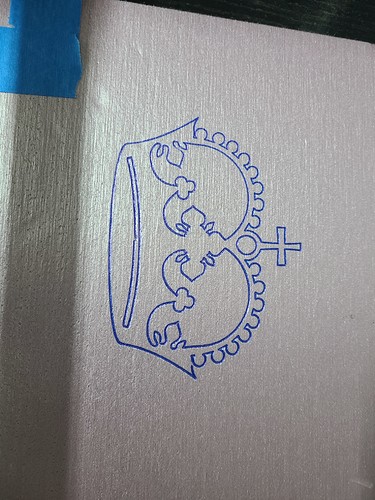

Well… I’ve done it now… not 100% finished yet, but it’s functional. Still need to extend cables, make enclosure for controls, come up with some sort of cable management and mount the dewalt… made a successful crown!

Just need some help with speed settings. Moved like a snail. I know I either missed something, or set a setting incorrectly. Moves quickly in between “cuts”, so definitely something I have set wrong.

Figured out my slow speed issue… mm per minute I’d slightly different than mm per second…

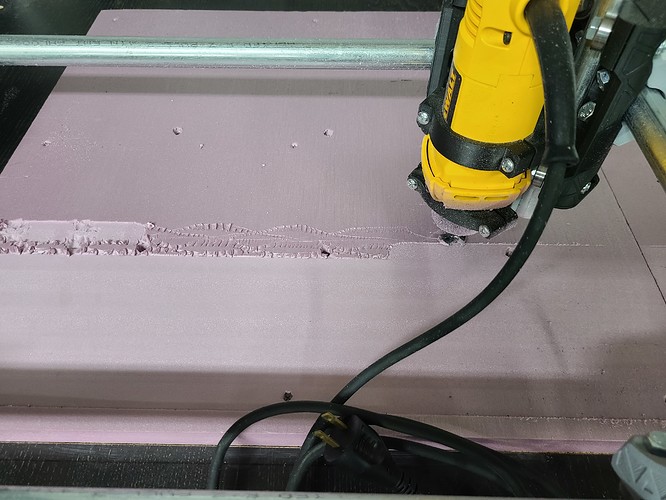

During the first ever spoil board surfacing on my new build (pink foam at first). … the dewalt660 had an issue with a brush in the motor and died mid pass.

Now I have to pull it apart and see if it is fixable or not. So far this is the only problem I have had and Happy to say it has nothing to do with the Ryan’s design!

Brush spring was hung up on side of brush holder. Centered on brush and watching it run the surfacing job again. Also, reduced feed rate and step over to 50%. So far, so good…