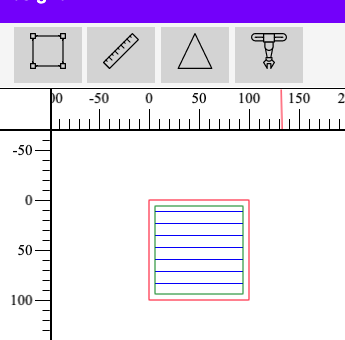

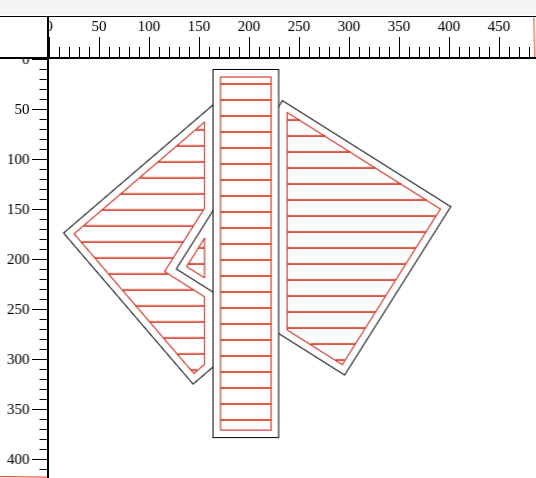

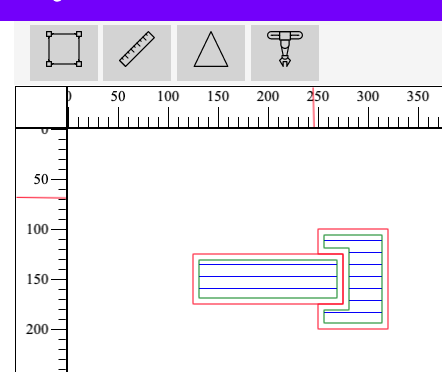

And lo and behold, I resolve one bug and can now generate this

The actual input for this is two rectangles. Here’s the cartesian points that describe them.

// Interlocking squares

var points17 = [

[

125,125,30,

275,125,30,

275,175,30,

125,175,30,

125,125,30

] ,

[

250,100,20,

320,100,20,

320,200,20,

250,200,20,

250,100,20

]

];

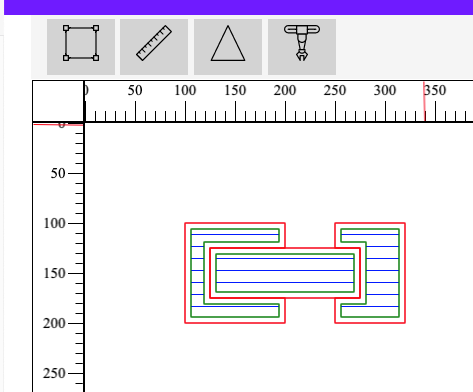

The program has worked out that the first rectangle in the array has a depth of 30 and therefore its deeper than the second rectangl which only has a depth of 20. Therefore it automatically cuts out a chunk of the second rectangle. The program generates the cut lines as well as the inner path to make a clean edge.

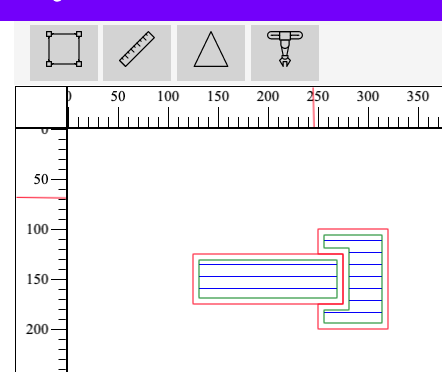

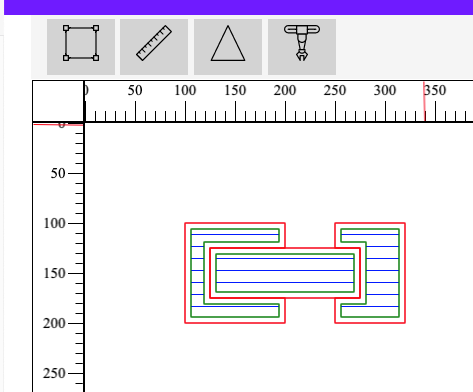

Here’s a more complex shape with three rectangles that intersect.

More complex polygons will also work, I use rectangles as that only has four points and I can do the maths in my head, whereas a complex star shaped polygon might have 12 points and I have no idea what the ‘right’ answer is.

A lot of this is new to me, so I have to go back to first principles to work out what I need to do, so it’s a bit slow, but it is coming along. The aim is to see how much I can do automatically before the user steps in.

Rob

The blue is a ‘cutting path’

The blue is a ‘cutting path’