Hi -

I put together a lowrider2, foam cutting machine, (SKR PRO dual endstop firmware) and it was working great until I broke a pin on the X axis port on the board. Soldering a new pin is beyond my technical capacity currently, so I rigged it up to where if you apply pressure to the connector, it works fine. When the pressure is off, it skips continuously (the end pin is not making contact… power?).

When rigged up, it seems to operate fine under load until the X axis skips. It will work for 20 or so deep plunge (50mm into foam) plunge passes, then will suddenly skip 5mm or so, destorying the part. I’m almost positive it’s because of the intermittent connection (read that on the forum about skipping) and it just started after the rigged pin.

2 questions…

-

Does the intermittent pin on the X axis sound like the culprit? Could it be anything else? Everything else appears to be working fine (belt, stepper, etc).

-

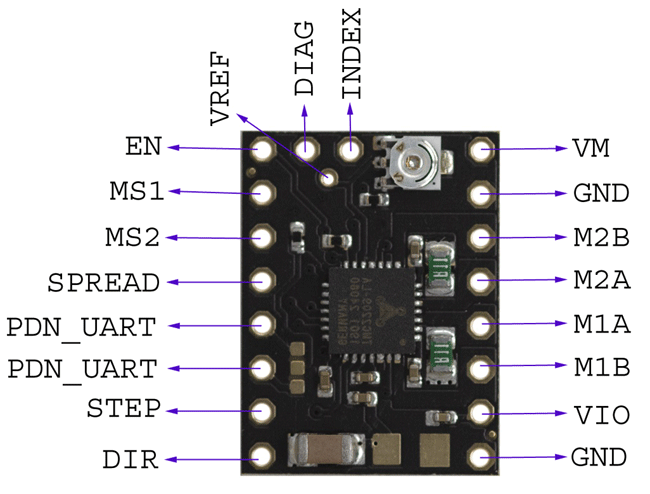

Is there a way to reconfigure the X axis port (X moto on wiring diagram) to use the unused port on the SKR Pro (E2 moto)? I ran into a dead end sorting through the firmware, but I have very little experience with CNC firmwares. Assuming X is 0, I want to make X port / driver 5.

Some pics:

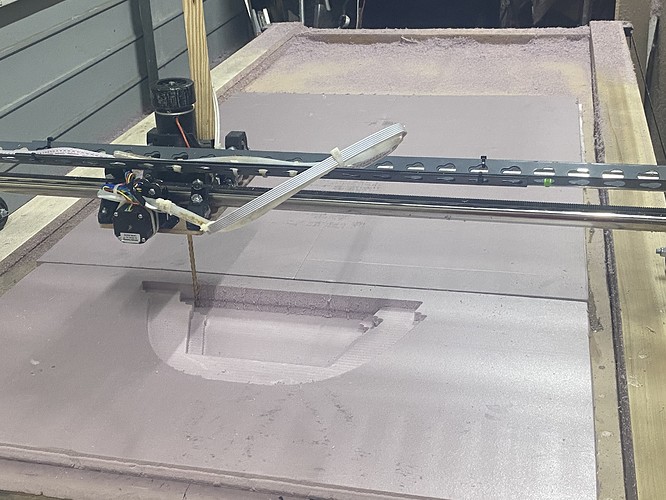

A picture of the rigged wire on the X axis (ziptie applying pressure to keep it connected) -

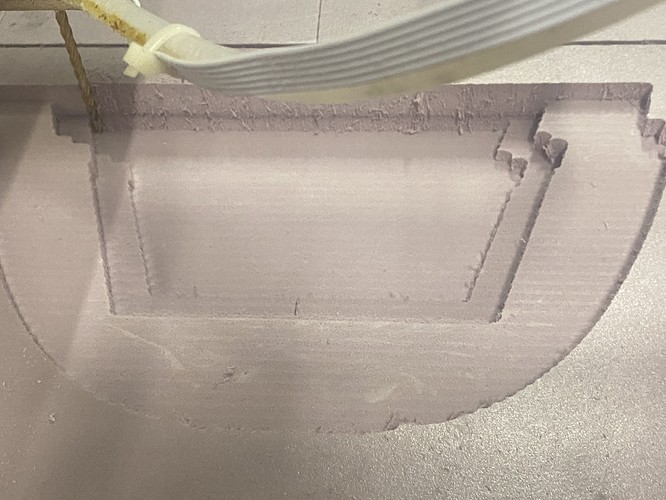

A picture of the awful skip that messed up the part -

And a picture of the whole thing…

Incidentally, the spoil board is removable and expands the cutting area to 150mm x 2200mm x 850mm.