Long time lurker’s first topic

I have been building MPCNC’s for years now (first one was 3 years ago)

Finally got around to upgrading it to a Primo so i figured i should get around to documenting my adventures here in case it helps anyone out.

By the way, Ryan’s documentation is fantastic, it saves you hours.

First in order of my machines designed by Ryan .

Part 1, the MPCNC original

Couple of photos of my first MPCNC (the original one before burly and primo)

This machine did not get much use due to time constraints, and it lacked some of the things i wanted

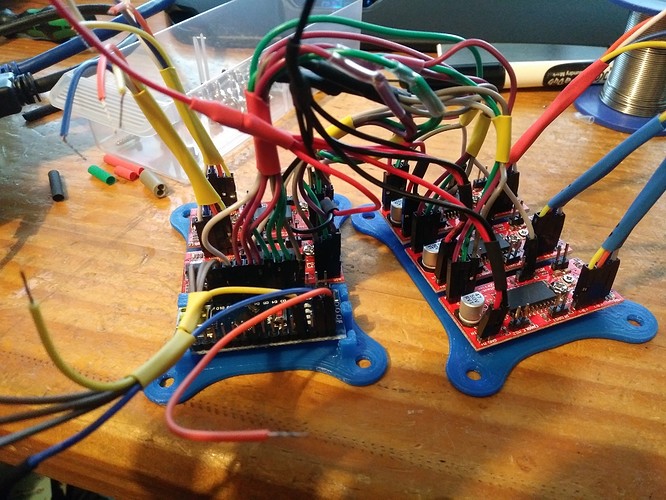

For one thing, the home built controller was awful.

(exhibit A)

So I decided after I moved house to just rebuild it with a decent controller, self squaring end stops, and GRBL (cause I like it, nothing against ramps, i just like GRBL)

Part 2, the MPCNC primo

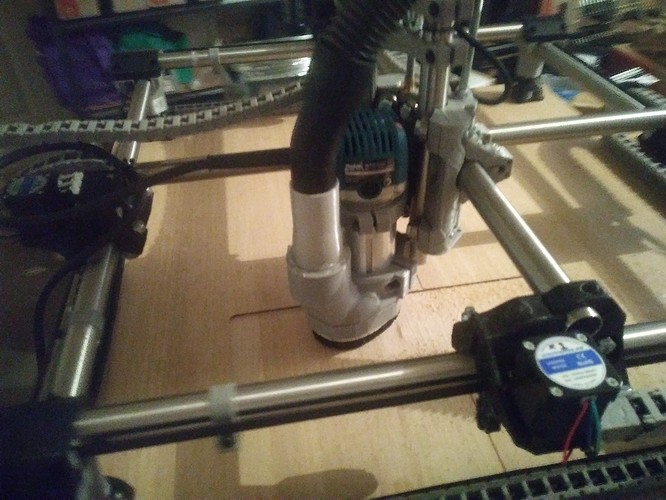

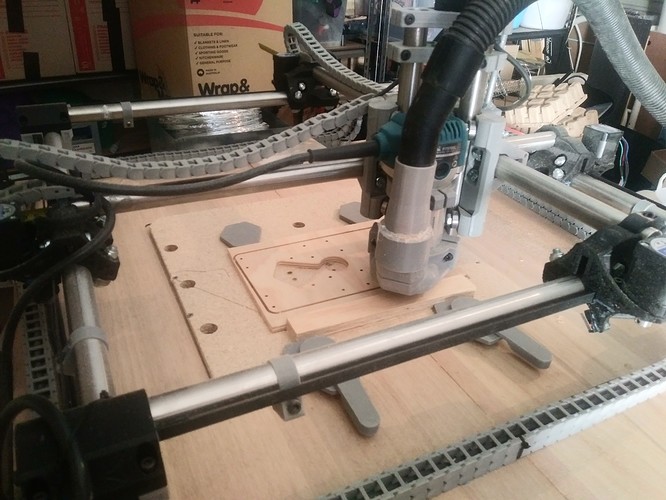

So this is the new machine (nice new primo) doing its bed leveling pass.

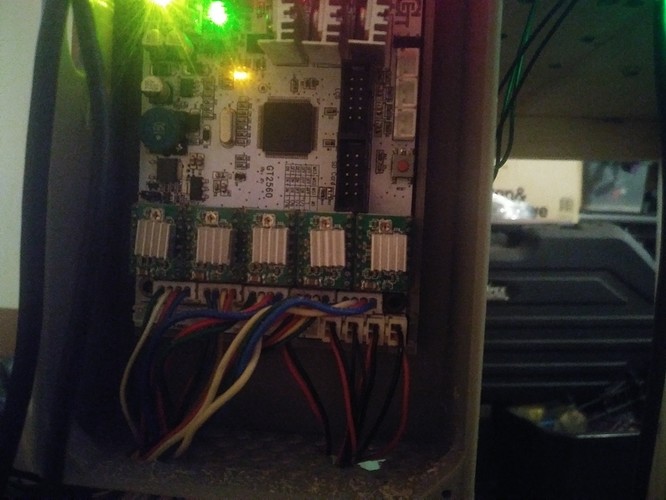

complete with self squaring end stops and a GT2560 controller from an old 3d printer

Its running a rather hacked version of GRBL Mega cause that supports 5 separate axis (which is how I am doing the self squaring)

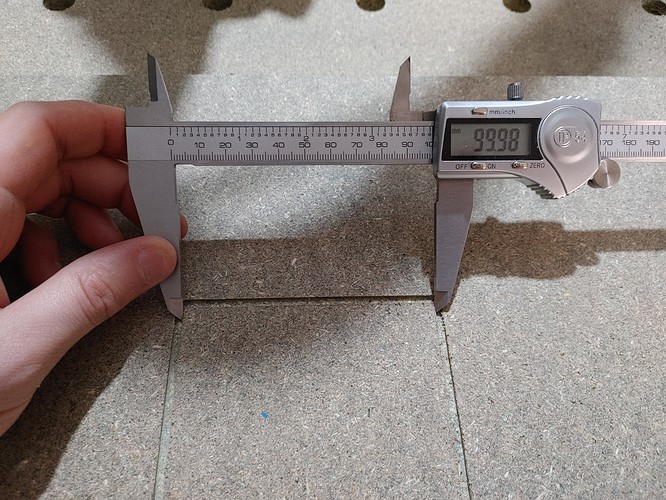

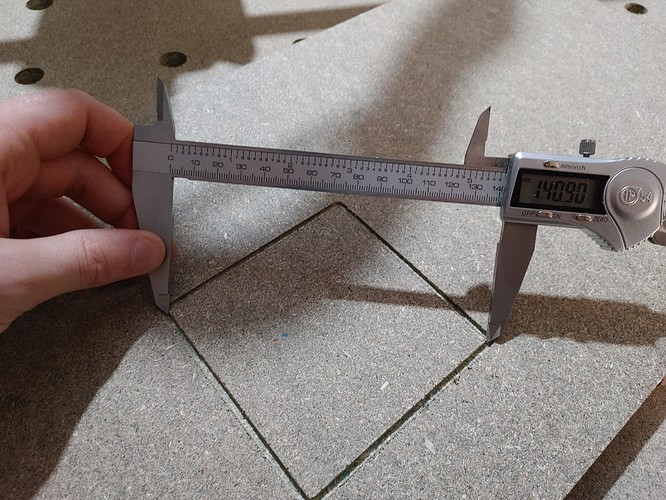

Self squaring once its all dialed in is amazing (i used a pair of calipers to position the stops, and many many square cuts to slowly dial it in)

within 0.1 square over 100mm, and within 0.05 on all axis over 100mm on the straights, I am happy.

Couple of notes, cable management is a pain, i still don’t really have a solution i am fully happy with, but the 3d printed cable chains work ok.

Second, this machine has TONS of torque, I am running 2 amp nema 17’s and i can turn the machine on and use the steppers to brace the gantry while I undo the collet nut on the router.

Be aware of this when cutting things like aluminum, if you bog the end mill down, at least with my setup, you will break the end mill before it skips steps. (not that I mind of course, just don’t bog it  )

)

then of course I wanted something larger.

Part 3, the Lowrider 2

So umm, lowrider 2 (much to the wife’s irritation) but I am using it to make stuff for her, so that’s slowly fading.

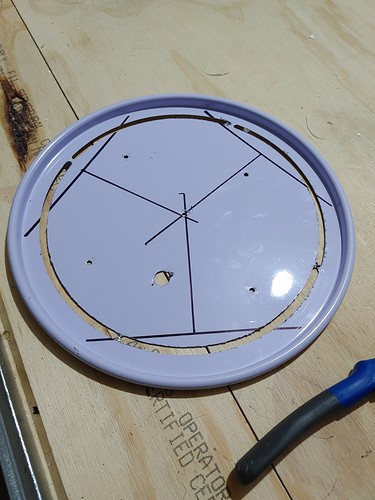

Cutting the router plate for the lowrider on the MPCNC

Lowrider assembled and cutting dog holes in its spoil board

Couple of notes

- Don’t do what I did, and put the lowrider top brackets on backwards, then wonder why things don’t line up and the lead screws jam up near the bottom of their travel (that was embarrassing and cost many hours of debugging)

- I found I was getting some wandering so I ran 2 guide rails (just steel angle) down the side of the bench

- I found it cut straighter with the addition of a steel plate joining the nuts holding the wheels, i suspect cause it makes the whole arrangement stiffer.

- cable management for the y axis on a lowrider is still something I don’t have sorted.

- self squaring on the lowrider is great

i know its not technically needed, but I really like being able to hit “home” and it will go square itself.

i know its not technically needed, but I really like being able to hit “home” and it will go square itself. - I don’t have a photo, but I am using a second GT2560 as the controller for the lowrider. Also running GRBL mega with a 5 axis setup.

Part 4, Aluminum

Then decided that I wanted to do Aluminum on the MPCNC, cause you know, why not

So first things first, air blast

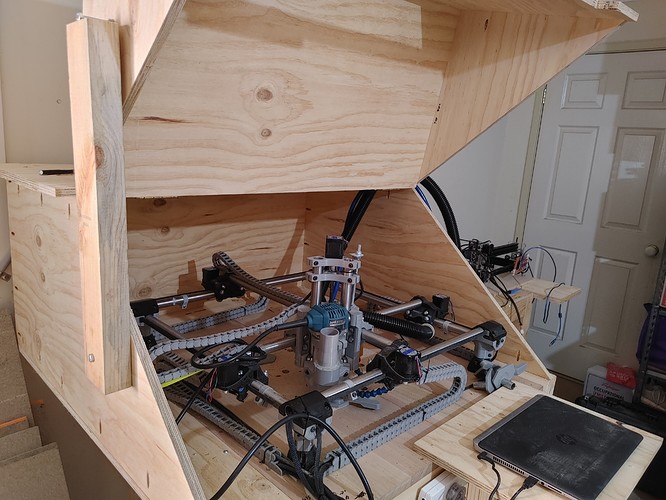

so, using the lowrider to cut a nice box for the MPCNC so I have something to stop Al chips getting blown all over the shop

and boxed

Much messing around with feed speeds / cut depths to find something that works in Aluminum

results of first working cut

Next project is to nick Matticustard 's idea for Aluminum brackets on the lowrider, and remaking the side plates and router plate in acrylic while I am it it.

Couple of other random things I have done with the MPCNC

Cutting really thin steel plate (cause I was lazy and cutting circles by hand is hard)

Don’t try this unless you have an endmill you want to trash, they don’t last long doing this.

machining blackbutt on the MPCNC

and the final results of that run

Finally, i have used MPCNC parts for things they were not really designed for.

I had a film shoot late last year and needed a camera slider for it.

So ummm, sorry Ryan

by the way, it was really smooth and quiet, so it worked, as much as these parts were not designed for this.

Anyway, thats me done, at least until I get started on the next thing.