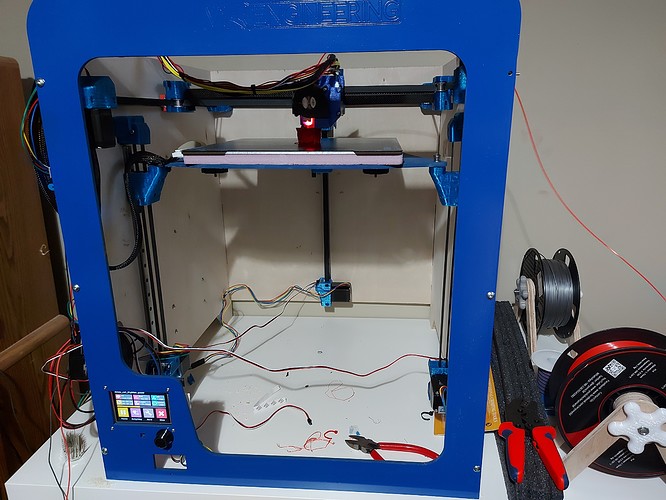

Okay, I don’t understand something…

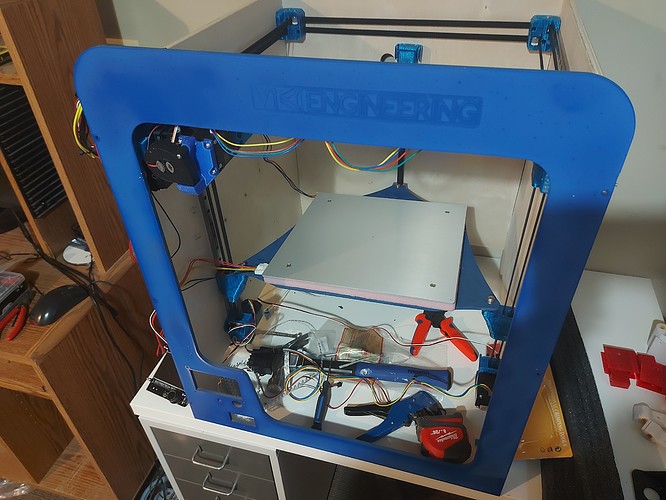

I consistently get a bit under 2mm of printing, then the print head picks the piece up off of the bed. I think when the bottom layer cools just enough, and it completely lets go.

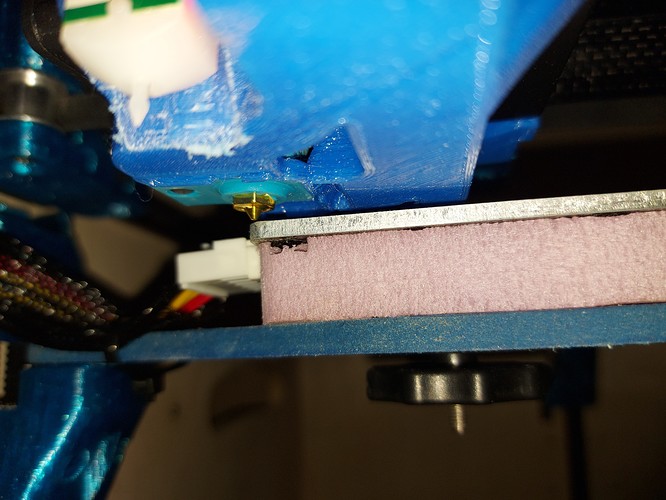

I looked at my first 2 prints, and throught that there wasn’t quite enough “squish” there, and maybe that would do the trick. I reduced the Z probe offset from 4.75mm to 4.65. Same result, and an identical looking first layer. Ok. Maybe a little more. 4.50. Nope. 4.2? That ought to have the first layer squished right down. Nope. no visible change at all in the first layer.

I don’t want to change it more, because I don’t want to crash the head into the print bed, so I’m looking for suggestions.

if you’ve got 10 minutes or so…

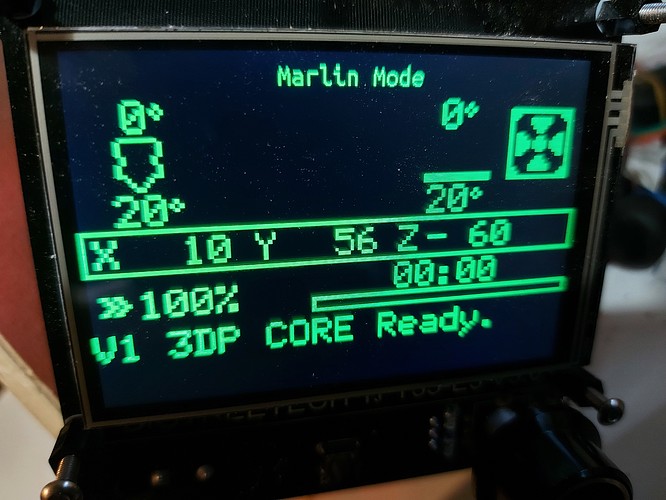

So first off, the G34 only uses the front left area of the bed… But still works. It has taken as few as 4 iterations, typically seems to take 7 or 8. I tried adjusting the probe positions but no dice.

G29, on the other hand works brilliantly, covering right to the edges of the printable area.

I’ve got 6 pieces now of the bottom 1.3-2mm of the same print lifted off of the bed. I don’t think I’ll give that bed surface purchase a very nice review on Amazon… but it could also well be that there simply isn’t enough squish. All 6 pieces, the first layer looks like it isn’t making good contact with the bed material, the “laying on top” look. Visually, there isn’t much gap between the nozzle and print bed, it doesn’t seem much different from my other printer (Also using a similar E3D V6 heat block) which has no such issues.

I was pretty sure that the probe offset should adjust the distance from nozzle to bed after completing the G34 and G29, but I’m not seeing a change. I’ll try compiling that change into the firmware. I’ll also look one more time for the G34 probe coordinates. I’m sure that closer to the edges of the print bed would produce better results, but that’s lower priority, since … it works.