Whew. I was worried you would curse us! I’m glad you had a good experience and I hope you try to find a few more projects to use it with.

Could you add a couple of pics of the box?

Called it!

Pretty soon, with some practice you’ll be wondering why you didn’t solder more stuff before.

Tip: Heat shrink tubing over the connectors keeps stuff from corroding and provides some strain relief.

I’m a big believer in soldering for electrical connections, because it’s secure and corrosion proof. That said, there are times when crimping is a better answer. Connectors in cars are crimped partly as a cost saving measure, and partly because the car is a hostile environment with lots of vibration and temperature extremes. Soldered wires subject to vibration and thermal expansion/contraction can break at the edge of the solder because it’s too rigid, where a crimped connector can allow a tiny amount of motion. This shouldn’t be a problem for the CNC, unless you are allowing the wires to move too close to the plug. Proper strain relief is necessary.

With that caveat, a good solder joint is a sure thing. I’m glad that your experience turned out well! Better tools = better outcomes.

It’s a work in progress right now. If I finish it this weekend I’ll post some pics. If it looks presentable…

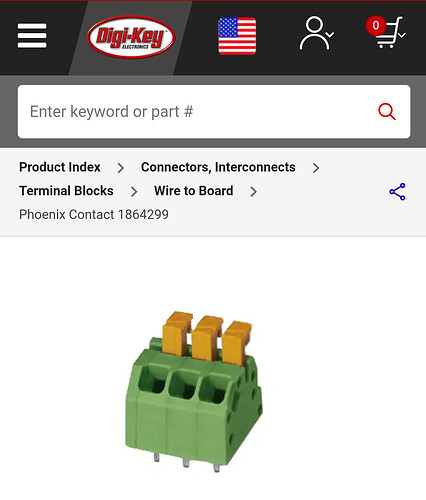

For those of you who don’t like solder or who often tinker with their machine and want a versatile solution that allows for quick changes, I recommend this kind of connectors:

I use these on my machine and they work great, very convenient stuff.

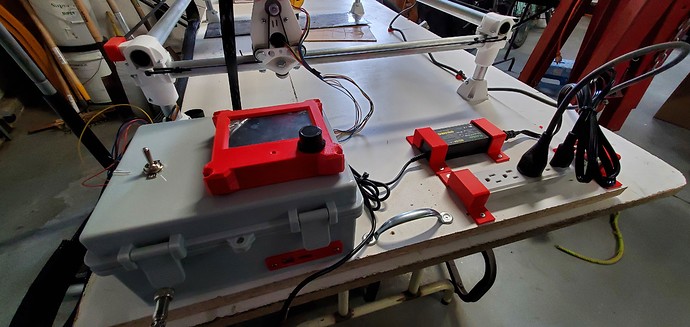

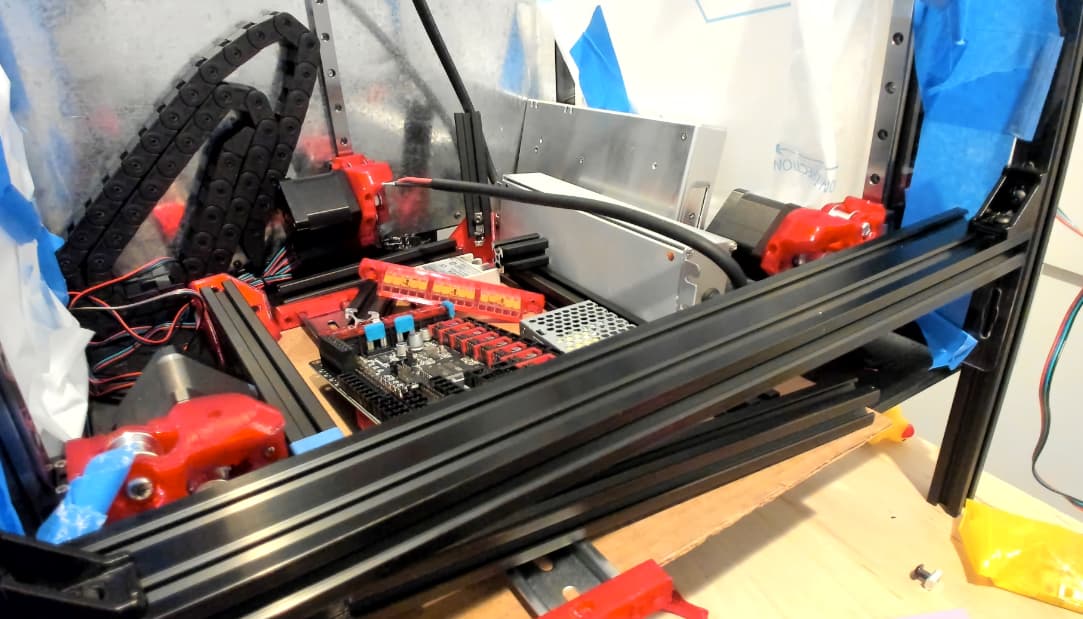

@neco, my box looks like this… I don’t recommend adding the mains stuff unless you are comfy with that kind of work:

Still a work in progress… haven’t found a foam seal for the door that I like. My connectors are phoenix contact brand 3.5mm pitch, mixed with some generic 3.5mm ones. Anything smaller pitch gets kinda hard to deal with for me. The motor connectors are a little bigger… not sure the exact brand but it is listed on Bart’s 6-pack github page.

Like forcerouge said, screw terminals are very convenient… and I’ll add that they are reliable enough to be used on the bulk of the ladder logic stuff you see in factory controller boxes these days. I suggest trying some higher quality ones bought from mouser, digikey, etc. They cost more, but you get what you pay for. Like phoenix contact ones really are nicer to work with the way they are made (a solid anvil vs a flexible spring sleeve).

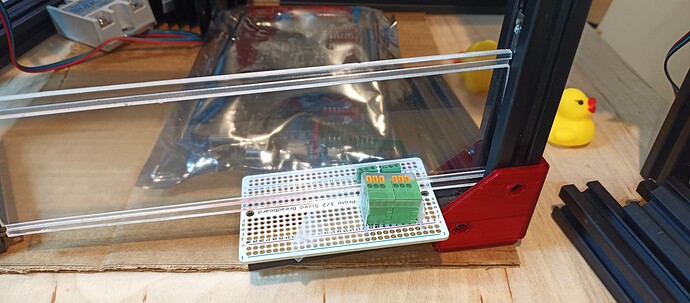

This is done for now. I still need to shorten the X & Y wires but this is good enough to get back to work on some real projects. I’m open to suggestions and/or criticisms.

Anyone able to recommend quick connecting plug connectors that can be panel mounted, carry 1.5A+, that use solderless screw/spring terminals? Aviation connectors require soldering which is PITA imo.

Looks promising, trying to find supplier for this or something similar. Am digging around via Image search for local/fast supplier.

Using WAGOs in the meantime as temporary solution. Haven’t ruled out D-Sub that can be crimped. Pluggable panel mounted solution would be nice.

1.5a at what voltage?

Max 24V, fans, steppers, gratuitously pimped out LEDs.

Will likely use something else for high currents and/or 120vac mains rated voltages.

Yeah those would be awesome! Get those on the steppers and the board. Ship a roll of wire and do some of the cleanest wiring ever super easily!

Not clear on what you’re thinking?

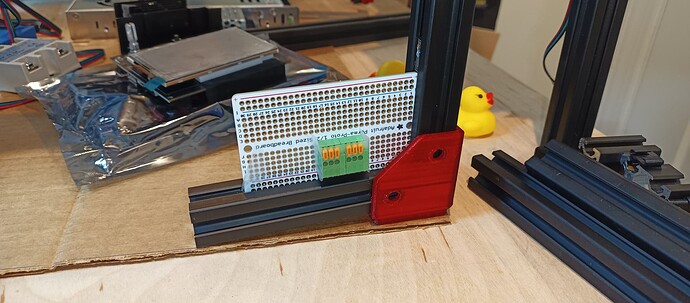

Was thinking a bridge board with spring terminals outside power/controller enclosure, screw terminals inside would be nice for low voltage ( 48v or less) components. Either, mount double sided bridge board like a panel, or, mount single sided version so it straddles inside outside the panel, like a meanwell psu. Here’s a rough janky visual aid of what am trying to communicate…

Not hung up on these specific board-to-wire spring connectors, they just what’s on hand

I wish we had these on the steppers, and on the control board, then we could run our own wires, end to end.

that’s why god invented wagos!

https://www.printables.com/model/420007-din-rail-clip-for-wago-221-2411-inline-connector

Nice! Thanks Barry, might try these instead of the extrusion mounted WAGO housings that Voron 2.4 or Voron Trident use. Hoping to build out enough that things need tidying up…

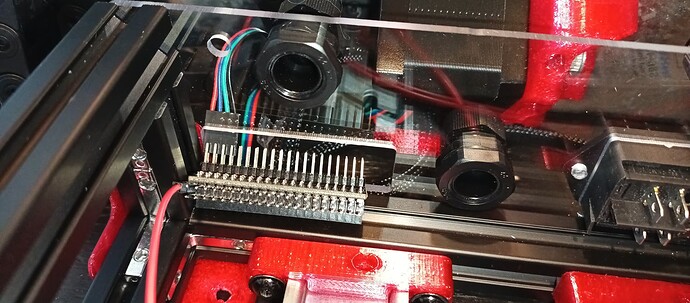

Running out of time for items to get delivered. Using/abusing Raspberry PI 20x2 connectors as Dupont extension connectors…