I’m curious to know if the Lowrider2 can cut 3/4” or 5/8” melamine nicely using the dewalt dwp611 and cut doors out of MDF. Can anyone reference videos or pictures of it being done?

Welcome @Kyled1996 to the forum. Here is a post that you might be interested in.

Also this one:

I use a Craftsman trim router and have done great with 3/4" MDF. The 611 would be even stronger and with a 6mm bit or smaller even should do fine. Others with LowRider experience will chime in.

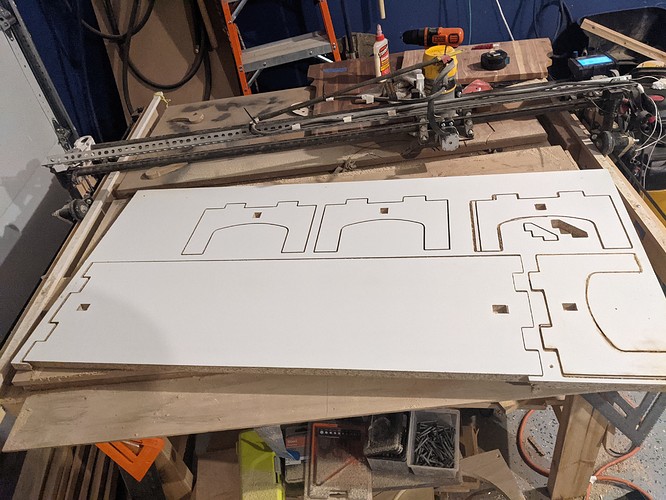

I can verify it does amazingly in 3/4" MDF! I cut a complete arcade cabinet out of MDF with my full sheet lowrider v2. I’m still assembling it, but it’s going together without a hitch. Here’s some photos in that particular topic.

I also cut a nice little stool from 3/4" Plywood (not sure of the actual type of wood. Home Depot has it listed as ‘Sande Wood’). Here’s that particular topic.

Keep in mind, I’m no professional by any means. I have barely had my LR2 assembled a month. I’d honestly be surprised if it’s even been a month yet. But I’ve found when there’s any issues, it’s generally user issues, and not the machine’s fault. There are so many helpful people here, they will get you on the right path!

Looks like it does the MDF quite well, I’d just be cutting rectangles out of a sheet for paintable fillers and such so I’m sure it wouldn’t be an issue there judging by what you’ve done with it. Any experience with 3/4” Melamine? Curious on the chip out

No melamine just yet, but I know a guy with one of those $25000 machines, and he told me masking tape is your friend when dealing with melamine. He gets that stuff vinyl shops use to mask the top side of the vinyl sticker, and covers the entire top of his melamine before he cuts it. As slow as the LR2 moves tho, I’d think as long as you had a new sharp bit, maybe an up & down cut spiral bit, it should be pretty clean. AND, a full depth finishing pass would clean things up super nicely I would imagine. I use a1/4" upcut 2 flute spiral bit, and in regular MDF, there’s literally zero tearing.

LR2 just shines in MDF in my opinion, those pockets I cut into the sides for the blocking, were so clean.

I haven’t cut any melamine on my Lowrider either, but past experience with a regular router showed a down cut spiral bit is your friend with melamine. I don’t think the Lowrider is any different in that respect.

I think it would probably work best to use a down cut for the first pass, and then switch to an upcut for the rest of a through cut.

A compression spiral bit would probably be best for a finishing pass, but I don’t know if they make those in the small (1/8" - 1/4") diameters we usually use on the Lowrider.

Thanks! Good info to keep in mind

AH! Compression bits!! That’s the name I was trying to think of when I said “Up & Down cut”! Thanks @Paradox_Pete! You can get them in 1/4" for sure, I have a few but have never used them myself.

I haven’t tried melamine, but I have used really cheap plywood. The kind of stuff where they saved money by not gluing the veneer down very well  . The downcut bit leaves a good surface on the top, and an ok surface on the bottom. An upcut bit leaves a good surface on the bottom and a bad surface on the top. With a downcut and a compression bit, you need to worry more about chip evacuation. Drilling small holes with either of them isn’t going to go well. Instead of messing with tool changes, I would just have a small peck (2mm or so) at the hole locations and then use the drill press to drill the complete holes.

. The downcut bit leaves a good surface on the top, and an ok surface on the bottom. An upcut bit leaves a good surface on the bottom and a bad surface on the top. With a downcut and a compression bit, you need to worry more about chip evacuation. Drilling small holes with either of them isn’t going to go well. Instead of messing with tool changes, I would just have a small peck (2mm or so) at the hole locations and then use the drill press to drill the complete holes.

I gave a whirl a while back to some melamine faced mdf, it was awesome. Only a small sample albeit but thought it looked great.

this was with a plain old 1/8" upcut even I think.I was looking for some feeds and speeds but only found that it was possible to cut melamine so decided to try it out.

My lowrider seems to have some flex (temperature is getting cold quick here in Indiana) so the following numbers are probably a bit conservative.

I tried 5.5 doc at 15 and 10 mm/s and motor skipped steps (grub screws are fine) on 3/4" melamine from home Depot using the long cut 1/8" bit from V1. Did another cut at 50% of 10mm/s at 5.5doc and the melamine started smoking.

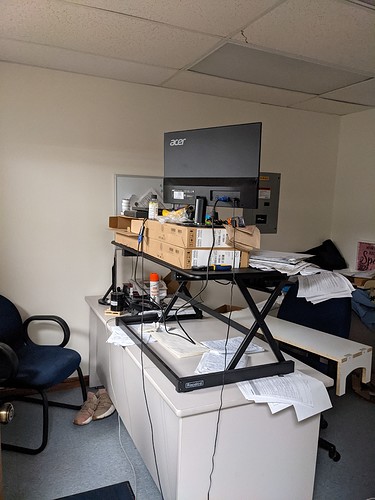

Needed to get the project done so went real conservative at 2 mm doc, 15 mm/s and no issues. No tear out and looked good. No post processing on the desk I made to replace a co-workers cardboard box stand.

This tiny staircases are a nice detail. How well did they work? I’m guessing you glued it all together?

Overall the project turned out fine but my design skills still have room for improvement lol. The pockets for the tiny stair cases (supposed to be horizontal bracing) were too small and the finger pockets were too big. Soo i put four screws in from the sides and held it together that way. Its stable, it was 11 pm, and i didn’t have another piece of melamine to do a Rev 2 so I called it good…

Looks better than the carboard boxes and its stable so I’m happy enough.

Screws work. No worries. Rev0 was cardboard. There is a lot of improvement to rev1. You won’t need a rev 2.

One of my co workers had two D ring binders as a laptop stand. I cnced him a new one out of OSB. I liked the look, so I clear coated it and shipped it to him (He lives in PA). He was very thankful, but when I asked him about he said he still hasn’t gotten around to painting it.  .

.

I do want to point out that this is not my office/desk, mine is only slightly less messy  . He put the cardboard boxes together, a very workable fix and screams thriftiness to all who visit which isn’t a bad thing

. He put the cardboard boxes together, a very workable fix and screams thriftiness to all who visit which isn’t a bad thing

Totally get the not wanting to paint part, that’s why I choose melamine-basically already done for you lol

And dang, willing to ship a laptop stand across state lines, that’s a good friend.