So, I have been trying to see why my lowrider doesn’t cut parts right, and so I created a square and made the machine draw it on a piece of paper, but when I connect my computer to the machine and used repetier host. The machine will move a little bit in the x axis and then repetier host would say that the job is finished but after a little bit the machine will keep moving. Also at different points it would tell me that there was an unknown command. This command said: “M140 S0”. The LCD also said the machine was at 50 on x and y when the machine was clearly moving. Any ideas?

It sounds like a poor signal getting to the board.

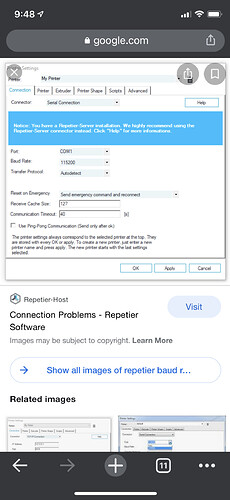

Start with the low hanging fruit… try a different usb cable the ones that come with the control boards are pretty crappy. Next try messing with the comm speed.

Sorry for the ignorance, but how do I mess with the comm speed?

Thanks, I’ll try

I don’t agree with that.

- M140 S0 is RH trying to turn off the heaters. That can be ignored. Otherwise, that little bit of gcode at the end of a file is probably configurable.

- Marlin will accept a small buffer of commands. If your square is only 4 lines, it might accept all of them, RH would think it was done, and Marlin would still be running through it’s buffer.

- Make sure the speeds in the gcode are in mm/min. Post the gcode here if you like

- Have you already tried the premade gcode test crown? That is known good gcode and you should make sure that runs without trouble before running your own to check out the machine.

I’ll gracefully defer to Jeff’s experience on this one… after I reread your op that had a specific command not just garbage I agree it’s not just a noisy connection that I was diagnosing.

No, I haven’t rested the crown. Where can I download it?

From the automatic link that pops up when you type test crown

Thank you for the help, I tried drawing the crown the first time and I found the problem with the machine. The x axis pulley was loose!!! such a simple problem but it made it impossible. I fixed that and now my test is working perfectly. Thank you again for the help