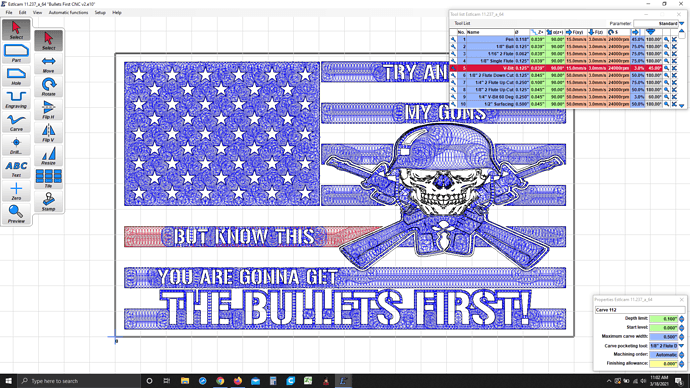

I have a couple successful carving projects under my belt and am trying to set up my next project. I made an 11x21" flag and a 16" diameter sign, both with fairly intricate designs. Neither of these projects took more than a little over an hour. My next project is a similar flag with a very intricate design and I am using a V bit and trying a pocketing bit for the first time. This current project is predicting a total time of around 9 hours and I don’t even have the tool paths finished yet. Does that seem normal or is there some way I can speed things up without sacrificing quality? I can’t imagine babysitting this for that long and it can’t be good for the router to run that long continuously.

Don’t know why after a day and a half and over 50 views I didn’t get any responses to this but I posted the same question in the Estlcam Facebook group and got a couple great suggestions. In case anyone runs into a similar problem in the future I was able to reduce the total time to under 4 hours by changing the pocketing bit from 1/8" to 1/4". I also changed the carving bit from 1/8" 45 degree to 1/4" 60 degree. I don’t know if the carving bit had any effect on it or not but at least I won’t have to change the collet.

What’s the depth of your carve? Does your pocketing tool need to do multiple passes to reach your target depth?

I set the max depth to 0.100". Yes it would require multiple passes the way I set it up originally. Probably 2 passes. I ran into a problem though when I tried to run my modified gcode. After the pocketing was done it paused for me to change the bit but it stopped in a random spot over a pocket leaving me with no way to zero the tool change. I was running it from Octoprint and the movement buttons were greyed out. The LCD had a message to click to continue and when I did it just continued on with the carve. I had no way to change the tool and rezero Z. It ended up ruining a $10 piece of wood.

I ended up redoing the Estlcam programming, switching to just a V bit and breaking it down into 3 separate carves (no tool change). It ended up at just over 5 hours total but each carve section was manageable and gave me a chance for a break from babysitting it between each section.

You could probably save yourself some time and do it in a single pass at full depth. I use CNC.js and for my tool changes I need to click the TFT and then I can jog it with the computer program to a location I can tool change I then hit run on CNC.js and it runs through the tool change process and resets z. Octoprint might allow the same thing?

What board are you using? I have a Rambo and couldn’t get CNC.js to work very good for me. I had V1Pi set up but I think the card got corrupted or something so I went back to just Octoprint. I would like to use CNC.js but it just connects and then doesn’t respond. I think there’s some gcode you enter and then it works but I can’t remember what that was and couldn’t find the info again so I gave up. I do remember the machine position readings just showed all zeros even when it did respond to commands.

As far as depths go I am still new to this and really don’t know what I can or can’t use for depths. You’re probably right on going full depth but I have been going very conservative so far.

I am using the skr pro board and I don’t know enough about the electronics to tell you why it wouldn’t work for yours unfortunately. I like the customization of Cnc.js as the live layout view. With some custom buttons it’s really nice to work with. The only downside is you can’t make any custom buttons without being connected to the machine.