Been building this machine on and off for awhile now and noticed that my center assembly is not level! Tried to take a picture but it’s not the best. My question is: is this a problem with my Z assemblies (needing to readjust screws and such until level) or is it a bigger problem with my Y Plates not being cut perfect? Any insight would be awesome before I tear into it this week!

Jake,

Did you cut your Y plates out yourself? they could be off a little. or your brackets that hold the tubes could be turned a little.

Is the Z all the way down?

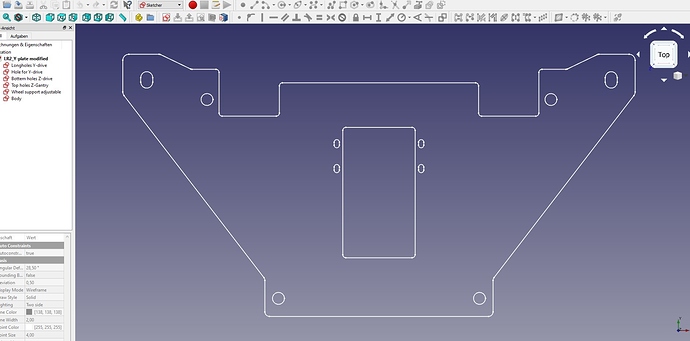

Yes, I cut my own plates using the following template and flush trim router bit + drill press to ensure as much accuracy as possible: https://www.thingiverse.com/thing:3364669

I may just try to mill my own or have a new set cut on an MPCNC I’ll have access to in a few weeks but wanted to run the issue by the hive mind first! I’ve messed with the Z assemblies but with little success so dreading it’s my plates.

Yes, Z is all the way down or “homed” since I’m actually running dual endstops, but can confirm those are not the culprit or “in the way” at all.

Seems like a simple test would be to lay a level across the two Y rails, note the bubble, then check the level of the router plate and your table. That should show you all the differences. If your Y plates are off, the Y rails and router plate will be in sync, but off from the table. If the rails and table are in sync, then there’s something up with the router plate, or the bearings therein.

If the Z rails are not parallel this can happen. Measure the top of them and the bottom, out of the machine, the numbers should be extremely close.

I had that with my first set of Y-plates. It was about 8-9mm/m

A limit switch on my dual stop MPCNC failed, so the MPCNC wasn’t square, nor the Y-plates.

A second set the Lowrider did for itself came out way better, that solved my problem with the level, I’m now below 1mm/m

I modified a bit the Y-plates, adding Longholes for the skaterwheels and the Stepper, however if you manage to get your hands on a good set of Y-plates none of that is needed, I figured out that if I tighten my wheels to bad, so to keep it secured in position, they stop turning.

The only other addition is a bit more space around the upper holes, as plywood tends to break of easy close to the holes.