I need to cut a circular hole in a square part. I can’t get the hole centered within the square. I ground a pointed bit from 1/4 round stock and used that to dead center it on the part that was center zeroed and marked by crossing diagonal lines, corner to corner, that are dead on. Still…the cut hole is off center by two mm or so in both the X and Y axis. Either axis is off square by less than 2mm over 25"… I just can’t figure what the issue is. The square stock is 180mm and square…the hole is 120mm diameter. There is no discernible lost motion or movement anywhere that I can find in the CNC. Thanks for your help!

Easy if you’re using hte CNC to cut the whole thing., but that’s not what you’re doing.

Three ways I might deal with this:

-

have a registered 0, 0 “fence” to clamp the work to. It need not be at the machine 0, 0 location, but you have to know what those coordinates are. Now you set up your job to cut a round hole centered in your work piece.

-

Drill a pin into the spoilboard. This is a little easier, because you an use the CNC to drill a hole of known diameter into the spoilboard. Since you used the CNC machine to do it, you will know the exact location. Make it say 1/4" Drill a matching hole in the work piece at the center of the circle and use a 1/4" pin to hold the work there. now make your 120mm circle centered on that pin, and you’re good to go.

-

Get a touchplate that allows you to register the X/Y/Z position of your stock. You can get these that cover a corner of the workpiece and will allow you to set the X, Y and Z positions of the work piece exactly with your machine. They need a little bit of set-up and aren’t normally supported in this way with stock V1 firmware, so you’d need a bit of modification there, but they can be very effective once dialled in for precision.

Center-Hole.gcode (3.4 KB)

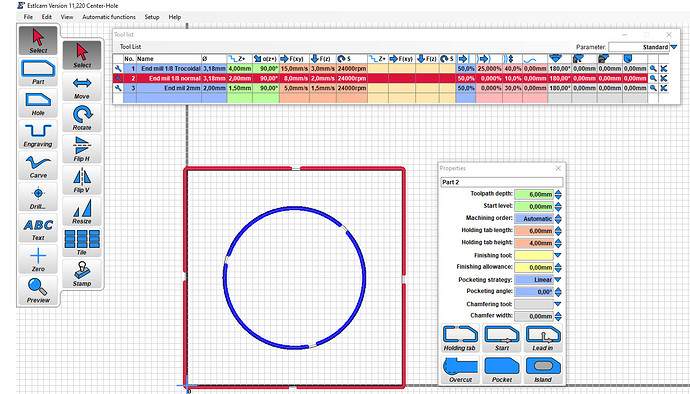

It would be even easier if you import the dxf file in Estlcam and generate the gcode for the two operations (hole + part) I am attaching the image of Estlcam (180mm panel with the 120mm hole inside) If You like you can download the dxf file and the gcode compiled for a thickness of 6 mm to be cut with 1/8 "bit from this link: Example - Google Drive.

If you haven’t installed Estlcam yet, try to download the trial version and import the dxf to make the piece of the correct thickness.

I hope I was useful to you.

B.R. Paolo

I usually do use a 0,0 fence. This project was a bit different. Then pin hole in the spoilboard worked perfectly. I should have thought about that. Thanks.

I made a corner touchplate a while back but haven’t used it yet…or set it up.

Hi…and thanks for your help. I do own Estlcam. I used Sketchup 8 ( with the dxf/stl plugin) to design the project…Estlcam then Repetier host.