I’m ready to give some proper MDF a try. For me it’s all okay to use this as a reference. I guess it’s the most consistent material, on a global scale.

I still think MDF is your best bet.

I think it’s the particle board that my lowe’s labels as MDF.

I’ll fire it up on Sunday! I’ve got a CAM cut that’s 5min 30sec, looking forward to see how it goes

I have until Sunday to beat that time…

That is pretty nuts. It is getting hard to shave time off at 9min.

I don’t think it will matter much. If your mdf makes it hard, go try some more. If it gives you an unfair advantage, then it probably won’t be huge.

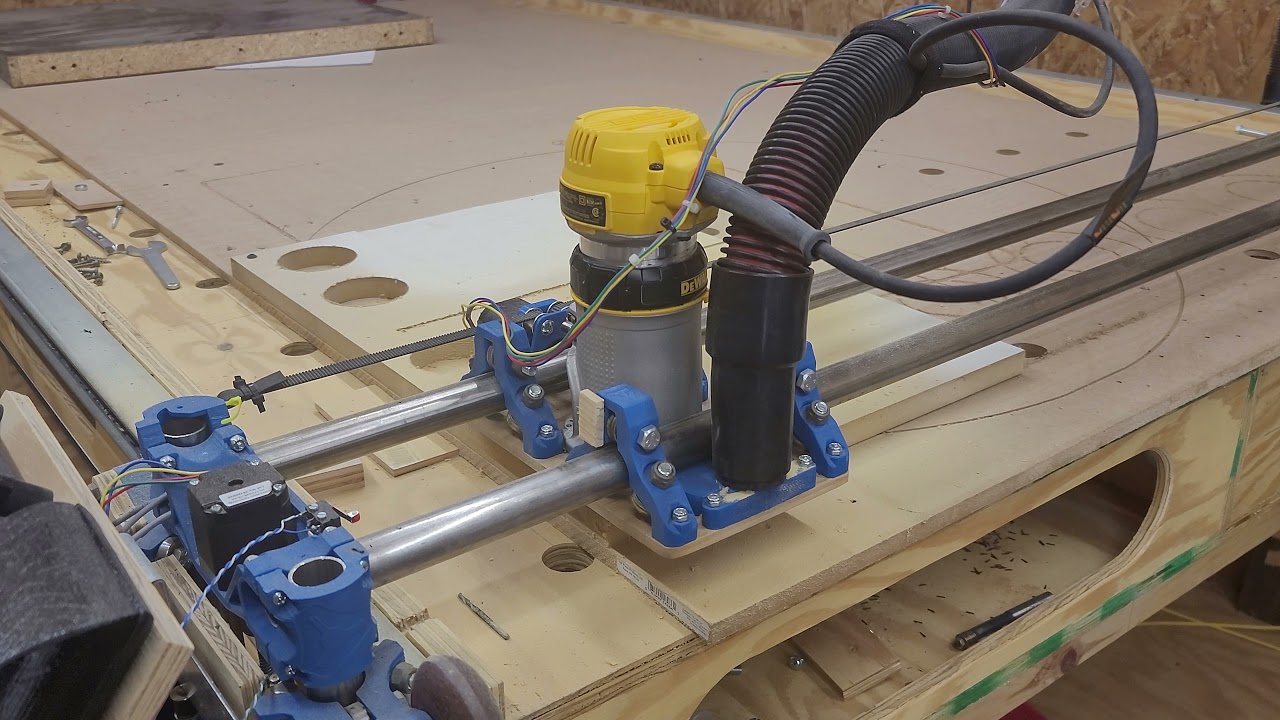

I grabbed some MDF from HD while I was picking up a new saw blade today. It will be a good first-ish project for my new LR table.

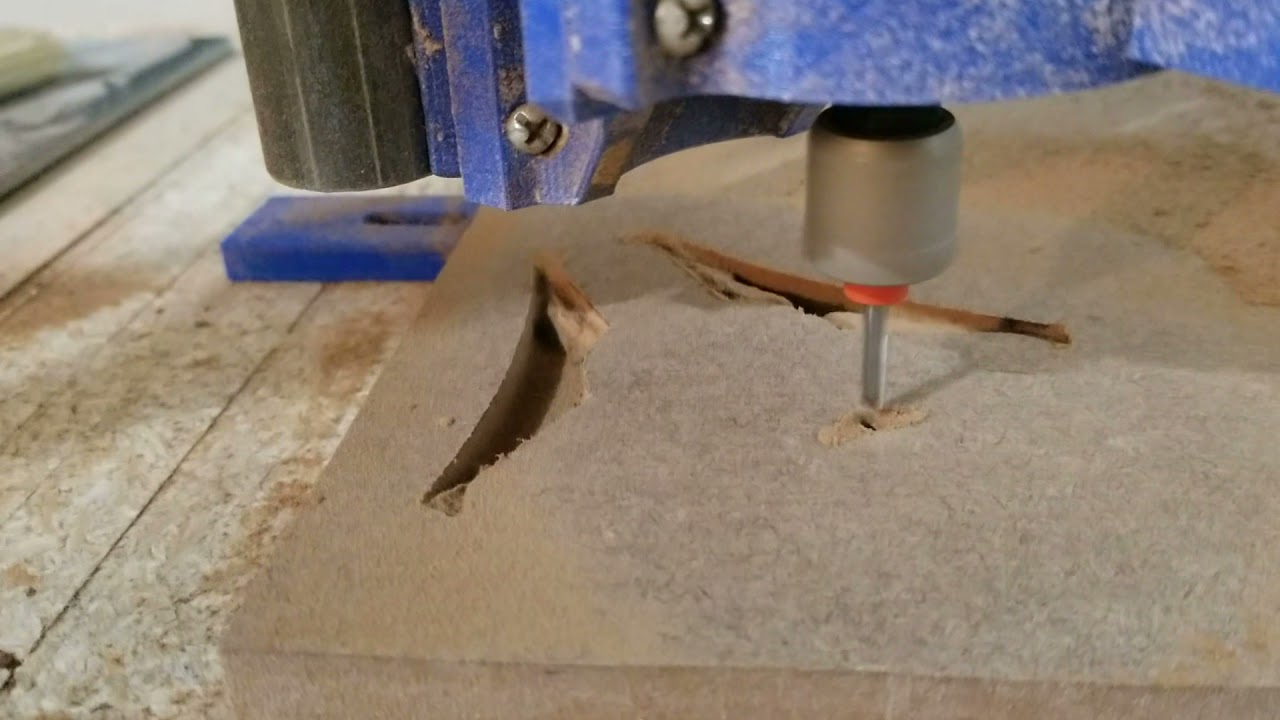

![]() Heck yeah it will!

Heck yeah it will!

I might try to find some time to give this a go this weekend. I picked up a welder this week and have been spending all my free time trying to figure out how to melt metal to my will.

I just spent the last few hours welding half a frame together, last weekend it was half a roll cage. Careful letting your neighbors know you can kinda weld!

I can’t weld, yet.

I’ve ran about 10 beads so far. They’re useable, but they don’t look great. I did try to break one weld with a 4’ cheater bar and the metal only bent. I consider that a good sign.

A grinder and paint makes me the welder I ain’t

Using my baseline settings for wood without touching anything except increasing DOC from 5 to 6, “quick” but not too aggressive, I got about 6:00 for half depth, which would be about 12 minutes for full depth. So that’s not too far off from Ryan’s starting point.

But it’s an interesting problem to optimize the hog-out rate, maximizing the volumetric removal rate. This really needs a test pattern generator to systematically test numerous combinations of depth, feedrate, and stepover to find the boundary of what is viable for a given machine, bit, and material. I think there is a lot of performance being left on the table to avoid the risk and cognitive load of operating closer to the edge. By probing that space on a test piece of the same material, it should be possible to capture more of that performance without that much risk.

Right!? This is way more fun than I expected…and I was pretty excited already. This is a more complex problem than I expected and so far I have not been as “right” as I thought with my choices.

I am comfortable running the rapids, at max on the MPCNC 50/18mm/s minimizing non cutting moves decreases the benefit of this anyway. I expected the 4mmdoc-6mmdoc to be a huge jump, not just 12%.

I can’t wait to run some more tests!!!

Crap! I’ve been catching up on other stuff after my second covid shot knocking me out for a day and a half!

There’s still time. Just don’t start any

Where’s the fun in that?

If it makes it faster…or a better video. That might qualify for both!

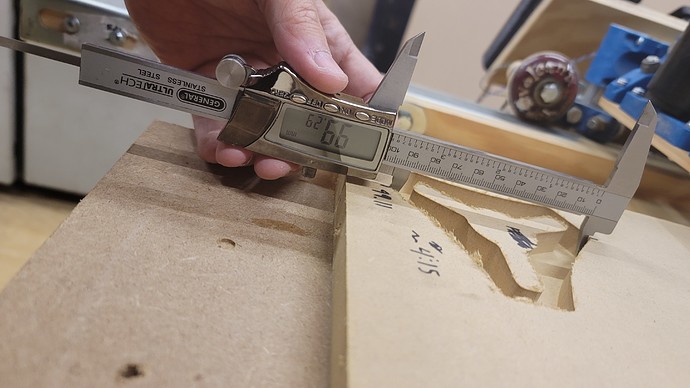

99.26

12.55

about 4:15! Dumbass me forgot to hook up the dust collector, so everything is gritty now…!

Think I can do it single pass.

Ohhhhh the 1/4" is fast! I have a single and a dual flute 1/4…I guess I know what is next.

…AND Barry takes the LEAD!