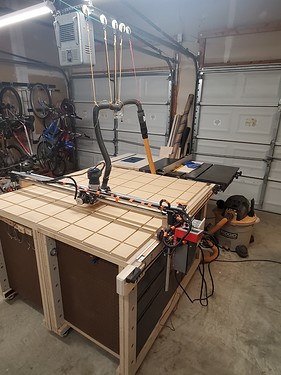

Picked up my LR2 back in May '20 - I guess it’s a COVID build, but I was looking to pick a CNC up before that hit anyway - a good excuse though. This was back in Colorado Springs area, I got it built, drew the crown and then got orders to move to DC area. So into a box it went. Tonight, I completed the rebuild. Now to officially post it here. Let the learning begin! I’ll keep this thread going with the testing and lessons learned.

It looks terrific, but I would say that because even an open box of bits would look terrific next to my “build”!

The unistrut tracks look great, but I have a question regarding keeping the timber inserts level with the table on which the wheels ride- my concern is that the thinner track pieces can/will move/warp/buckle or even gradually build up dust underneath them. What will you do to keep that from happening? I love the look!

It’s definitely a first run attempt. The strip of wood is because I tried without it and just have the wheels snug into the miter track, but the gutter was too deep that the printed parts dragged a touch - didn’t want that, so in went the strips of .25 ply. I had a piece of T-track and I think this is where I will go, once I order enough to put in. I can secure it down into the miter track and the wheels will sit and run in the groove of the track.

As to having it flush with the table top, I’ll need to do some trial and error on this. One thought comes to mind - once I have it where I need I can put in a few set screws to keep the rails from movement.

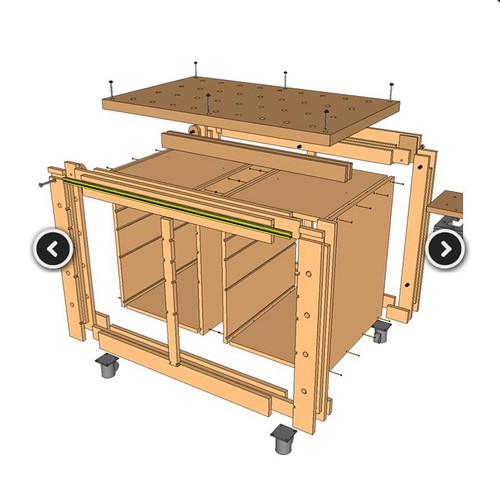

Did I mention that I love your “modular” bench? I have space for a 1200 x 900 (4x3) table, but my heart says “full sheet would be nice”. My head says “not until I have a job for it” so my one third module it is!

Check out my muse’s youtube videos through his website: paoson.com he’s got two about his workbenches. I suggest you look at the main full sheet capable bench/workstation. Then watch his modular set. Very inspiring. All three of my benches are made in similar fashion. I intended to make just 2 at 6’ but a rush of free materials came available and now I have two at 52" to fit the free drawers and enough materials to make two more squirreled away.

These are neat videos. I also have been eying the new series by shopnation on youtube. I like the size (72"x48"). That is big enough for just over half of a 5’x5’ Baltic birch plywood sheet. The construction is easy too. Not modular though.

There’s another video that breaks down that large one into four modular sets like the one above. If you would rather adjust the width of them to make it 2’6" wide, it will fit your 60x60 sheets of birch. Then you’ll need to just make the LR2 bigger.

I (personally) don’t have that much room where my cnc is. I also can’t fit a whole 60"x60" sheet in my little car. So I have them cut down to 30"x60" at the store.

But this is still probably too big for my needs.