I’ll reluctantly jump in here to see if I can help… hopefully, not overwhelm/confuse. I’ve successfully hooked up a number of cheap import lasers to my various machines and been able to get virtually all of them running. NO GUARANTEES… but this is what I’ve found with the lasers I have experience with.

Most diode lasers (like most of the ones asked about on this forum) come in flavors… 2-wire, 3-wire, and 4-wire. Two of the wires are most certainly for power… any others are usually associated with intensity control (PWM). The voltage levels are commonly +12 volts for power… and either +12v or +5v for the PWM (this is where most of the confusion seems to be… when vendor info doesn’t specify the level). PWM (pulse-width modulation) speaks to the switching ON/OFF of a voltage level (commonly +12v or +5v)… with the duty-cycle (ratio of ON time to total period) controlling the average voltage… and thus the intensity of the laser output.

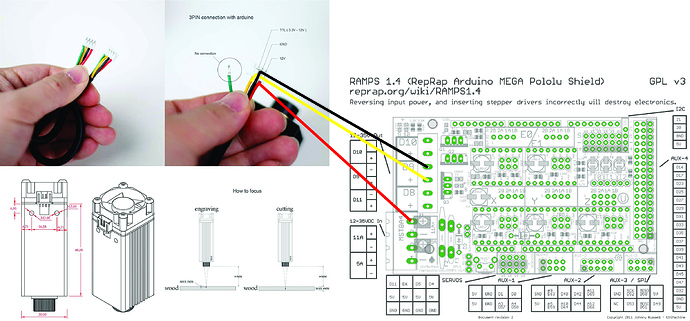

2-wire lasers (an L-Cheapo 2.1 watt laser a friend had falls into the category) usually are +12v lasers. Hooked to a constant +12v DC, they come on at full power… with no intensity control. Hooked to a +12v PWM signal, like the D9 fan signal from RAMPS and MKS Gen L, you can vary the intensity with the M106/M107 fan speed gcodes. L-Cheapo worked fine simply connected to the D9 fan screw terminals on a RAMPS board… be sure to observe polarity. That’s about all I can say about the 2-wire lasers I’ve seen.

4-wire lasers (my Banggood 3.5 watt lasers have had this) usually have two 2-pin connectors… one for +12v power and one for PWM. One wire in each connector is a GND wire. The power connector wires are simply hooked to the same +12v DC power as the controller board you are using. I also found somewhere in the provided info that the PWM levels for this laser is +5v only. M106/M107 gcodes are convenient and commonly used for controlling the part cooling fan (and lasers!) but this is a 12v PWM signal and can’t safely be hooked directly to the laser’s +5v PWM… so this is when pin “remapping” is used. Changing the D9 fan pin assignment (in “pins.h” IIRC) from “9” to “44” (RAMPS and MKS Gen L) allows the same M106/M107 gcodes to now control pin 44, which is a +5v signal… same PWM, different levels. And this can now be safely connected to laser’s PWM connector… pin 44 to the + and the - connects to a convenient GND.

3-wire lasers (the Eleksmaker 2.5 watt lasers I have) have a single 3-pin connector… if labelled, usually +. -, and PWM. The PWM levels are also +5v. These lasers are virtually the same hookup as the 4-wire lasers above… but share a single GND wire. So +12v power connects to laser’s + and - as usual… and pin 44 connects to the PWM pin.

In the photo below, note the red and black power wires hooked to the controller board (here, a MKS Gen L)… on the lower left side. Note also a couple of isolated wires, white and gray (straight across the board from the power connector)… these are the PWM control pins; i.e. white is pin 44 (remapped D9 fan pin) and gray is GND. These are all the wires needed to control your laser. The red and black are +12v DC power and will connect to the 3-/4-wire laser’s power connector (red to + and black to -) and the white “pin44” and gray “GND” wires will connect to the 4-wire laser’s PWM connector (white “pin44” to + and gray to -)… or, in the 3-wire case, the white “pin44” simply connects to the PWM pin in the laser’s 3-wire connector.

[attachment file=107841]

I’ve never used any of the more expensive lasers – JTech, Endurance, etc. – but it appears that, among other things, they have taken some pains to make a more robust/flexible PWM input. I suspect that the connections I described above would work fine for the ones that specify a range of PWM levels extending down to +5v or less. Pin remapping might not be necessary if you can find a suitable, already-existing PWM (D9 fan output?) signal… but I doubt it’ll hurt anything; i.e. hooking a +5v PWM signal to +12v-only PWM laser input might not modulate it properly but, at least, it should not blow it up, either.

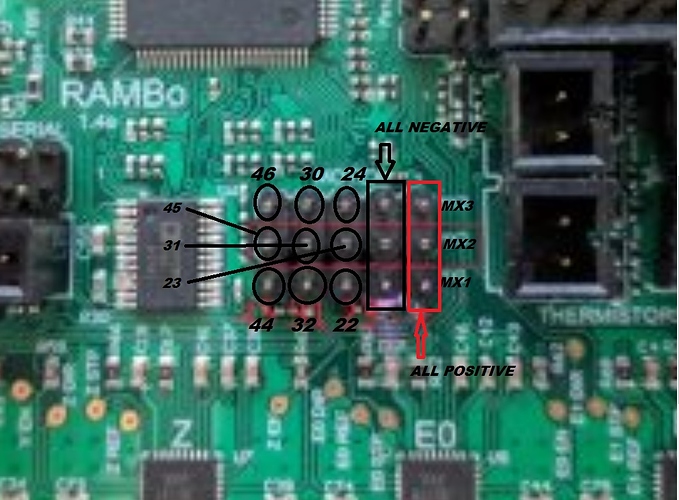

The only other thing here, different controller boards won’t have a “pin 44”… but there will be a suitable pin somewhere that you can remap the part-cooling fan output to… and still allow for M106/M107 gcode control. On my miniRambo, that was the Z-min (pin 10) endstop pin IIRC.

I hope this helps someone. These laser connection questions are asked so many times, hopefully a more general explanation will help you figure out what you’ve got.

– David