Yesterday I was asked to build a wardrobe for a fair with a big party tent. I’ll first explain why and how. I am a member of an amateur musical group.

To earn some money to buy stuff for the musicals we take care of a wardrobe at the annual fair in Gaanderen (the Netherlands). It is in a truck trailer. When people go to the big party tent and want to hang up their coat, hey bring it to us and pay an amount of money to hang it up and guard it. They get a token to get their coats back when they want to go home. All members of the musical group have a shift in the wardrobe. The earned money goes to the club. Normally we earn about 1500 euros a year by doing so.

3 years ago the wardrobe broke down, I temporarily fixed it (saturday night 02:00…), but now I need to build a new one. The wardrobe needs new tokens. These are quite expensive. Think about 650 euro for 1200 double ones. One stays in the wardrobe, the other is given to the client and received back in exchange for their coats.

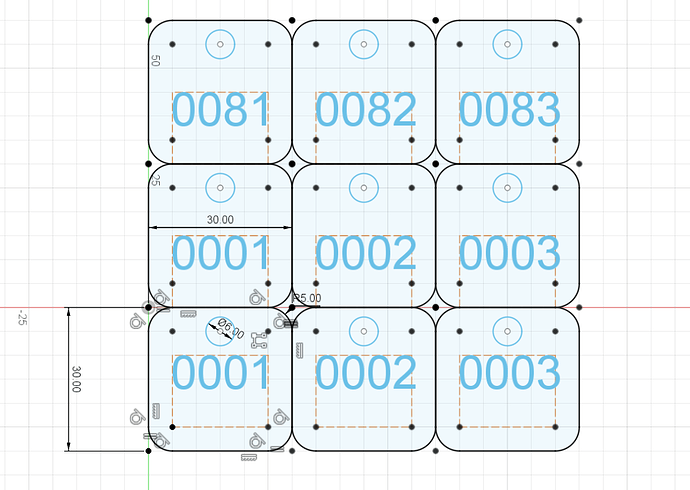

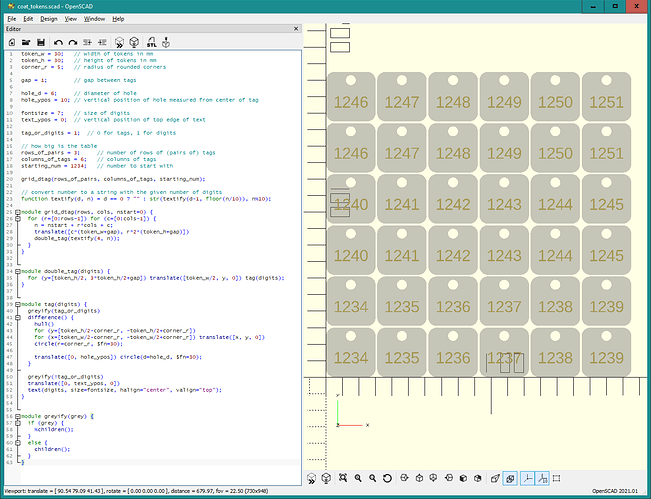

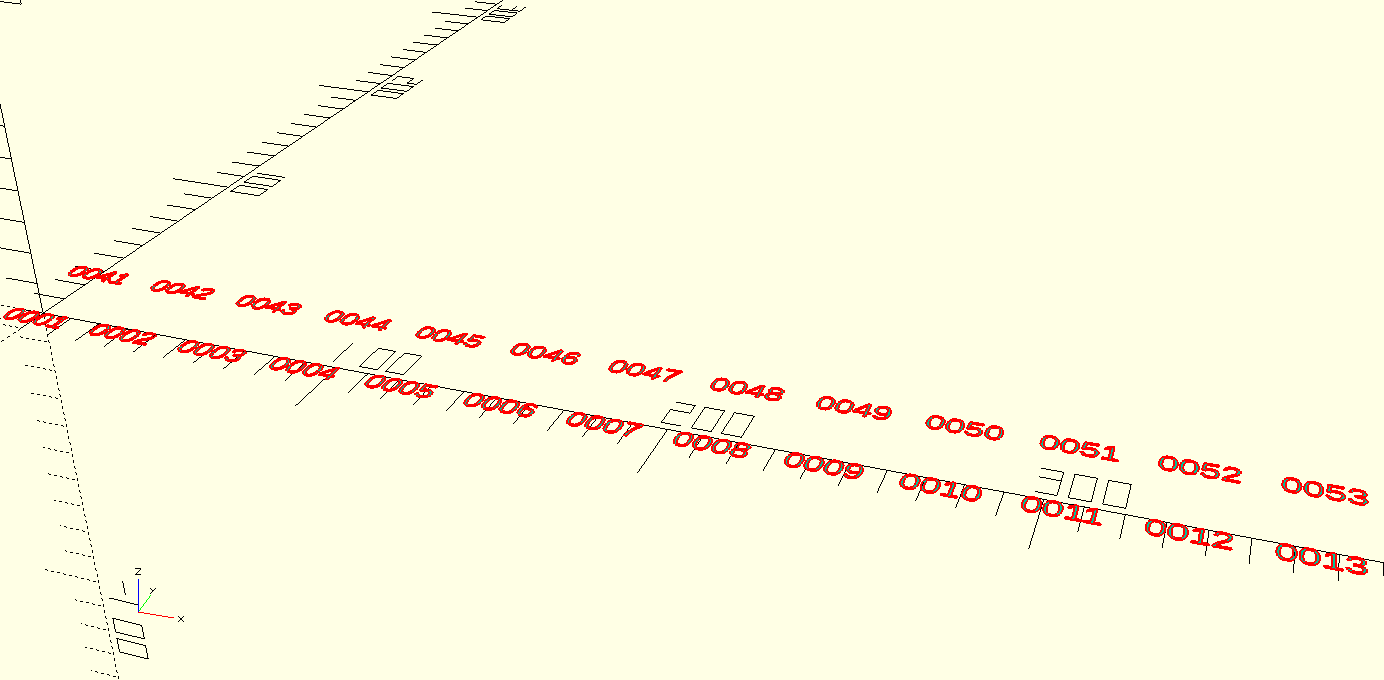

I was thinking if it would be possible to mill our own tokens with a lowrider2 or 3. The lowrider 3 is in its finishing stages right now. When i make the tokens about 33 cm, I could make about 3200 of them out of 1 sheet of 12202400 mm. I already made a test drawing.

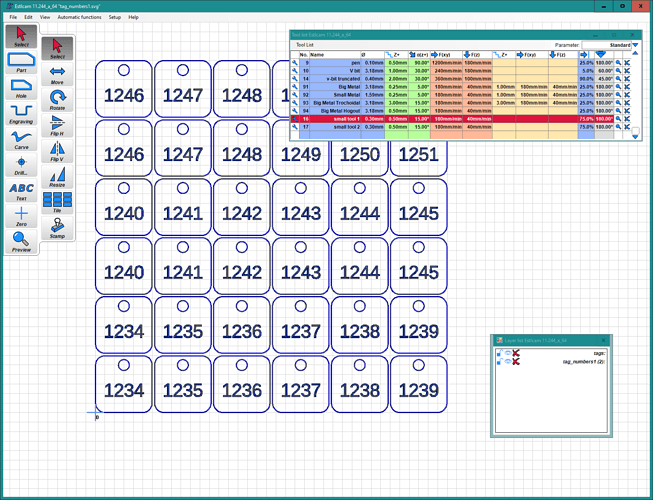

Now the real question. I want to make tokens with consecutive numbers: 0001-0002 until 1599. Does anyone know a way to do that in fusion360 or another program, including CAM? I normally use

fusion360 (i have a teacher licence) and ESTLCAM. I cant find a way to automate stuff. can you help me and our club?

It should be something like this: