For the sake of discussion, i was cutting a 4 inch tube with 1/4 inch wall thickness, designed in Inkscape and then in Estlcam. Board is maple approx 1/2 in thick. Started with the hole cut out and then part cut. Using a 1/8 endmill bit. When the job was completed the wall thickness was 0.1 in instead of 0.25.

What did I do wrong, how do correct.

I dont have the image at work with me, but simply a 4 inch circle with a 3.75 inch circle.

A 4 inch circle with a 3.75 inch circle should yield a .125 inch thick wall provided you cut the 3.75 hole on the inside of the circle and the part cut on the outside of the circle.

Yes inner circle was cut using hole function, and outer circle was cut using part function. So am I not accounting for for tool diameter? If I am looking for exact fit, how do I calc that and where would that adjustment be made, inner circle or outer?

Thanks for the help.

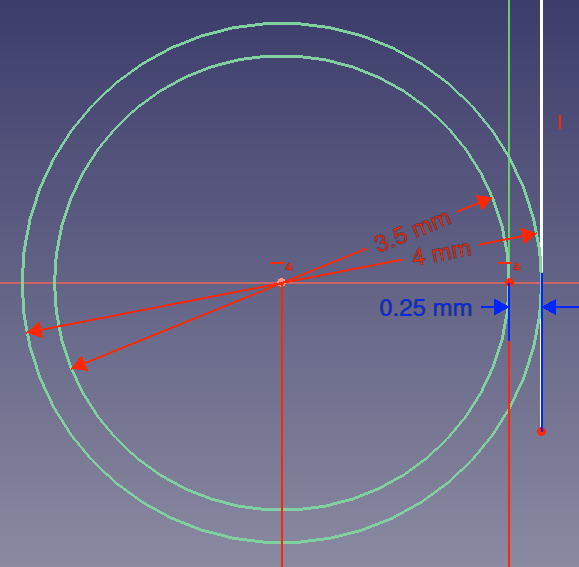

I think what Paul is saying is your inner circle needs to be smaller for 0.25" wall thickness. This is in mm but same idea.

You originally said the wall should be .25, shouldn’t that be .125? Did you measure the tool used to confirm its size and also check if it runs true? Cutting both ‘hole’ and ‘part’ would make the wall thickness off by any variation in set diameter vs. actual.

Yes, wall thickness will be 1/2 the difference of the diameters of the two circles so with the circle diameters given as 4" and 3.75", the wall would be .125"

I’ll have to measure the part, I only checked the thickness, I didn’t actually check the diameters.

The bit has the collar on it, 0.125. Will double check with calipers.

Don’t forget that one of the nice things with CNC is when something’s a bit ‘off’, you can always fudge a bit with the tool size you’ve set. I don’t know how common it is with smaller bits but when playing in a friend’s shop it was nice to be able to take reground/sharpened bits that were a little smaller than marked and compensate with the tool settings.

I measured the piece and the outer diameter is exactly 4 in as drawn. The inner was 3.82. I was under the impression that on hole and part functions that the tool would cut inside/outside the line and that would leave the drawn thickness, minus and play. Am I wrong in that?

No, you’re not wrong, that’s what it should do. To be honest, I don’t know where I’d be looking since the ‘part’ cut was spot on and the ‘hole’ cut is off. Just to satisfy my curiosity, I’d likely use the same drawing and cut the 4" circle as a hole to see if remained true to size or if it changed going from ‘part’ to ‘hole’. If it changed I guess I’d contact Christian? from Estlcam and ask for suggestions. Or maybe try the same dimensions with a square?

How were the circles drawn? With CAD that draws a circle with multiple straight segments like Tinkercad or as a smooth arc?

I created an svg file in Inkscape, then opened in Estlcam. I’m all set up to cut it again, but had to work this weekend, so tomorrow.

Hopefully someone smarter may step in, I’m pretty much limited to trying different things to isolate where if not why the problem occurs.