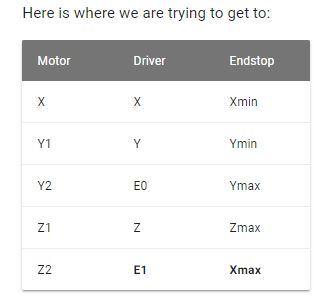

If this is really how you have your machine wired, then you’ve have a problem. Your Z2 and Y2 need to be swapped. The wiring according to this chart:

…pulled from this page, says Y2 gets the first extruder slot, and Z2 gets the second extruder slot.

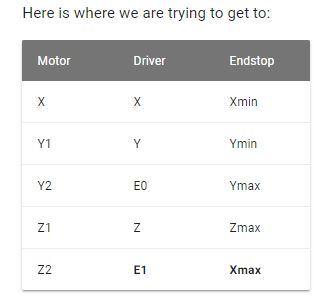

If this is really how you have your machine wired, then you’ve have a problem. Your Z2 and Y2 need to be swapped. The wiring according to this chart:

…pulled from this page, says Y2 gets the first extruder slot, and Z2 gets the second extruder slot.

Yeah, I did see that chart. Because grbl doesn’t have official Ryan support I had to go in and edit the firmware myself. So I just made the headers whatever I wanted. I can change it to match the chart if it helps people out.

You have enough uncommon choices here that it may be difficult for the forum with its narrow communication line, to figure out the problem. Maybe the place to start is to do a standard V1 install of Marlin including his wiring choices and see what happens. If it works, then you’ve pretty much identified the problem as something you’ve done in GRBL and the people on the list that know GRBL can help you track it down. If the problem persists, then we can begin looking at the software pipeline and hardware issues to track the problem down.

You might want to try looking into your acceleration settings for your Z axis. It would be $122. It may skip steps and not lift the Z high enough at the start of your run. Then when the commands come in to lower the Z, since gravity is working with the move, it works fine, but since it started lower, it plunges lower.

Now I don’t have a lowrider, but my Primo Z acceleration is set to 10mm/sec2. So $122=10.

Edit: Ach, nevermind. Just plugged your settings in and works fine, even pushing down on the Z during an up move.

I actually did end up flashing marlin to see if it would work for me. I got everything installed and I could jog the machine around, but I kept getting a weird error in the gcode sender. That being said, I used the wiring from the chart and edited the grbl firmware, so it should be what is expected.

I made the changes you listed above (motor current to 138, 2100mm/min for XY and 480mm/min for Z) and it seems like it’s working! I ran a surfacing operation and aside from some stair-stepping (which may be due to the dust brushes, I’ll look into that in a bit), it seems like it took the right cut and didn’t do anything weird!

@robertbu what uncommon choices did I make? This is my first time delving into anything CNC, so I don’t really know what I’m doing. I’d like to know for next time so it’s a smoother process!

@Strider_Matic I’m really new to all of this (if it wasn’t too obvious  and that was a good tip! I went through and checked all my settings in $$ and I had missed some. I also pulled up the config.h file from the normal grbl v1.1 and it seems like a lot of stuff was edited out. I imagine it’s not needed since the machine runs, but are there any other settings I should double check and make certain of?

and that was a good tip! I went through and checked all my settings in $$ and I had missed some. I also pulled up the config.h file from the normal grbl v1.1 and it seems like a lot of stuff was edited out. I imagine it’s not needed since the machine runs, but are there any other settings I should double check and make certain of?

Thanks for all the help you guys, I’m finally starting to see some progress with this machine!

GRBL is used by a tiny minority of MPCNC users, so if the issue was rooted in GRBL few on this list would have the experience to help you. The swapped wiring was also a bit of a surprise, and it made me wonder what other choices you made we were not seeing. I’m a big believer in starting from a simple working solution and evolving to get to where I want.

I’m really glad you seem to have this sorted. Good luck, and I look forward to seeing things you’ve made on the list.

As far as editing the grbl config.h file goes, I had to enable the variable speed spindle and additional enable pin settings, but I’m using an Arduino/CNC shield, and the V1 PID speed control, so I am even further down yet another low-occupancy branch of “what’s most popular” here on the forums. I puttered around with homing sequences, but once I realized my problem was due to noise on the switch lines I put it all back the way it started.

Once steps-per-mm is properly dialed in, the interrelated variables/tunable elements remaining in the motion control arena are motor current, velocity, and acceleration. Looks like you’ve identified which of these was the primary contributor to your issue but it might be helpful for further tuning to understand how they interrelate.

(Feel free to consider the rest here TL;DR)

Too little current and you don’t have the power to make the moves you want, too much current and drivers and motors get hotter than they should and the drivers start to cut out, which may present as vibration. On my 3D printer this presented as moire patterns in the plastic extrusions. Nothing stopped moving, but the motion was no longer smooth. Options here are to lower the current or add cooling (fans) to the drivers and possibly the motors.

Too high a velocity setting and you lose steps on long runs (where you actually get up to full speed) because stepper torque drops as velocity increases. Too high acceleration and you lose steps on all moves as the current provided to the motor isn’t adequate for the forces required to make the commanded move.

Current is tuned based on the amperage the motors can handle using the motor and driver specification sheets. Some controllers support “digi-pots” that can be set via software/firmware, others have physical pots that get tweaked. Once current is set, I’ve found it most useful to tune acceleration next by picking a very conservative velocity setting, then increasing the acceleration setting until steps are skipped, then backing the setting off 5-10% for a safety margin. With a known good acceleration setting you can then increase velocity settings until steps are lost and then back that off 5-10%. I’ve used this approach on 5 different machines and get very reliable motion control. I don’t worry about losing steps under most circumstances.

@jeffeb3 Is there a place I can put up a tutorial for getting grbl running on the lowrider? Might be a good resource for crazy people like me.

We don’t have any grbl in the docs. I think it is better that way for now. I would say a clean forum post in #software:grbl makes the most sense.