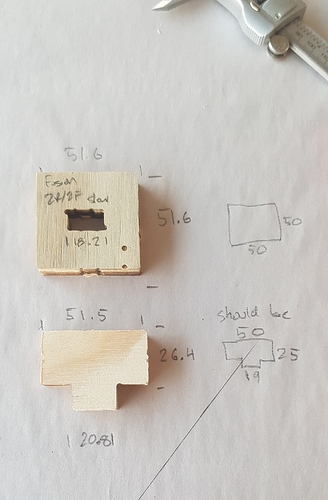

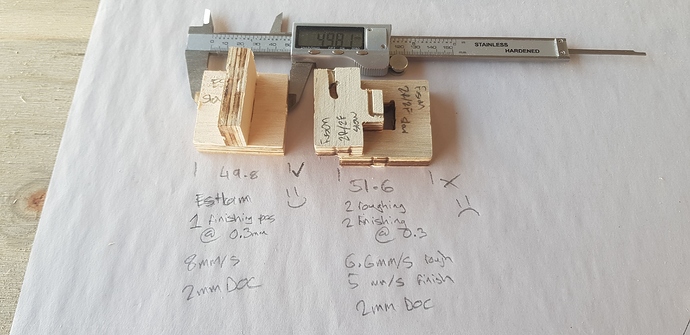

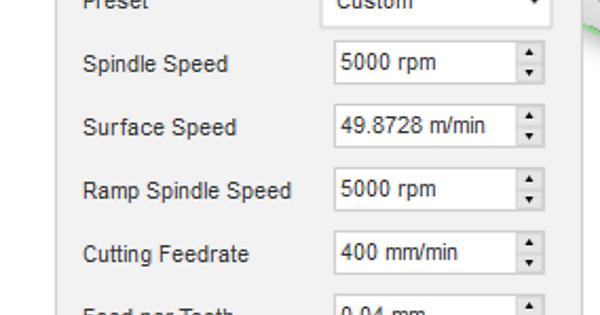

I think I’m missing a setting somewhere in Fusion. Cuts seem to be always leaving 1.5mm of stock. I took a nice slow approach, 2 roughing passes and 2 finishing passes with large tabs on this piece.

To test it wasn’t my machine, I cut the same DXF using ESTLcam to generate. The piece was cut right next to the previous, to minimise any belt issues etc.

The cuts were much more accurate.

I’m very suspicious of the difference being half my tool diameter. So I put in -1.5mm stock to leave, and lo and behold the part came out 1.5mm undersized!

Any hints? I’d prefer to use Fusion as it gives me a bit more control, and I’m already modelling in Fusion.