Probably the wrong place for this (Admins, please move to the correct place, if needed!), but, here I go.

Because I enjoy learning new programming systems (yes, I’m probably a little self-abusive!  ), and because I always have problems translating my ideas into useable code via the applications that I’ve tried so far, I decided to try to simplify some of it.

), and because I always have problems translating my ideas into useable code via the applications that I’ve tried so far, I decided to try to simplify some of it.

Most recently, it’s making oval/eliptical cuts. So, I worked out an Excel 13 spreadsheet to create the G-Code for me. I’m attaching it here (in a Zip format), in case anybody else wants to look at and/or use it.

The only 4 items that you need to change to generate your code are the X and Y center point coordinates, and the X and Y radius dimensions. (Remembering - like I didn’t, a couple of times - that these are radius and not diameter dimentions.) Your X and Y center point coordinates MUST be equal to or greater than the X and Y radius dimensions.

After you’re satisfied with what it will look like, you can copy and paste the G-Code into your own file using any decent text editor. Personal preference for me if Notepad++, but that’s just me. Please do remember to put a statement in after the first line to drop the tip of the cutter bit the necessary depth for your cut.

I’m using a MPCNC, and it works fine on it.

If it’s not fine enough in movement (which may occur if the overall dimensions get too big), please feel free to let me know. It is currently set up for 1-degree steps, but could easily be modified for 0.5-degree, 0.25-degree or 0.10-degree steps to smooth out your cuts. (Keep in mind that the higher the resilution - the smaller the steps - the more lines of G-Code you’ll have to copy and paste.)

If you have the need, you should be able to copy and paste only what you need for an eliptical arc, too.

Thanks,

David

PS: A parabolic arc will be next. Yep, I’m a glutton for punishment…

Ellipse - Oval Coordinates.zip (57.7 KB)

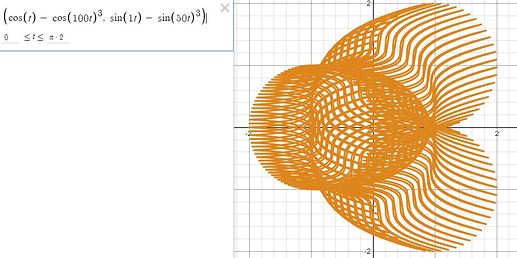

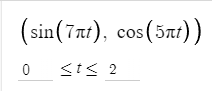

I couldn’t resist!

I couldn’t resist!