@christian-knuell

In version 11.244, finishing offsets and finishing passes in general are not behaving the way I would expect.

Finishing passes are important because I want to use a high feedrate to clear quickly and a slow feedrate to get a precise final surface. Even with an endmill and a tool change to clear out a lot of the open space, there are still a lot small areas that are only reachable by the v-bit. To clear out these areas takes a very long time if the v-bit feedrate is slow.

The finishing offset in the carve tool appears to offset only vertically, and only for the carve operation, not for the pocketing operation.

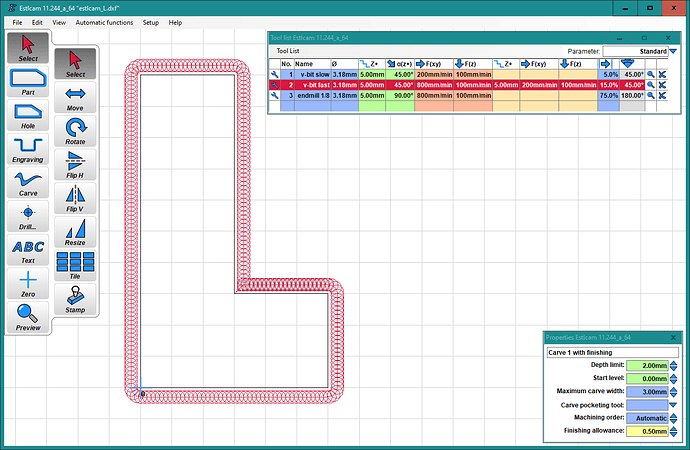

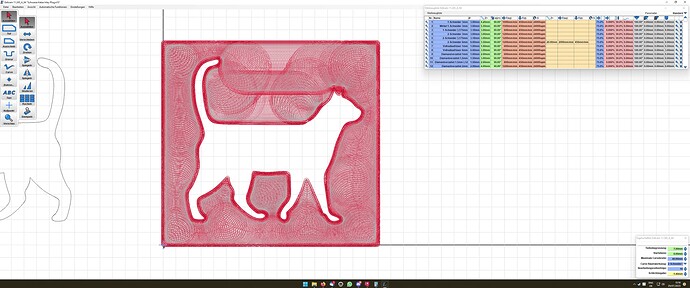

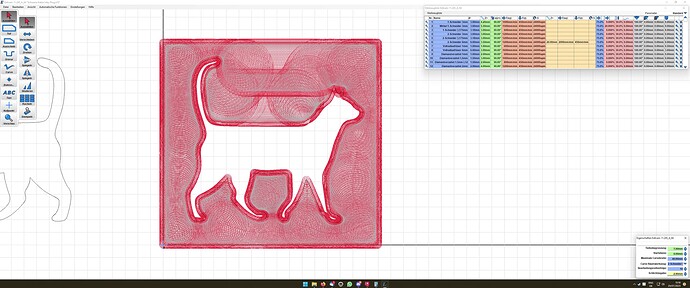

Here is an example with some simple artwork:

The “pocketing” which defines almost the entire perimeter, is performed only once, with no offset, and the interior corner is performed twice with a vertical offset.

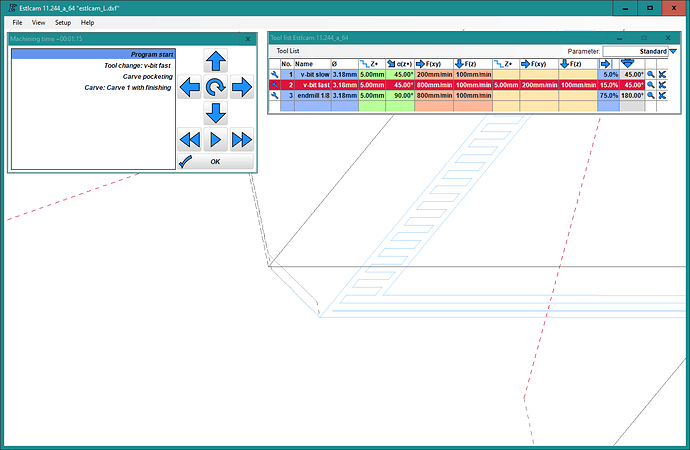

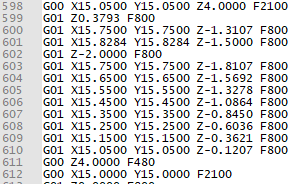

The carve itself occurs in this case by tracing diagonally downward along the upper (offset) line, then plunging to the full depth, and tracing upward along the final line. In the G-code, it is apparent that the vertical offset between the upper and lower carves is 0.5 mm (line 601 and 602), which is the finishing allowance that was specified. This means that the finishing allowance is a vertical allowance and not a radial X/Y allowance. This is somewhat surprising because finishing allowance is usually a radial (X/Y) allowance.

Also note that the finishing feedrate is not used for the finishing carve. The primary (roughing) feedrates are used for both the offset pass and the final pass.

Also, the carve operation is not respecting the conventional vs. climb milling preference.

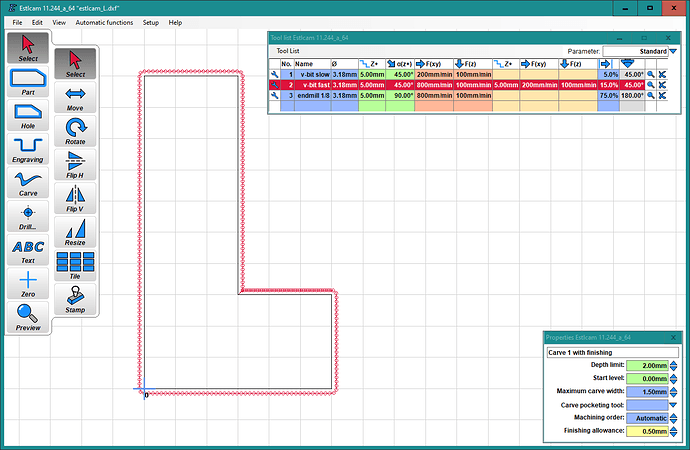

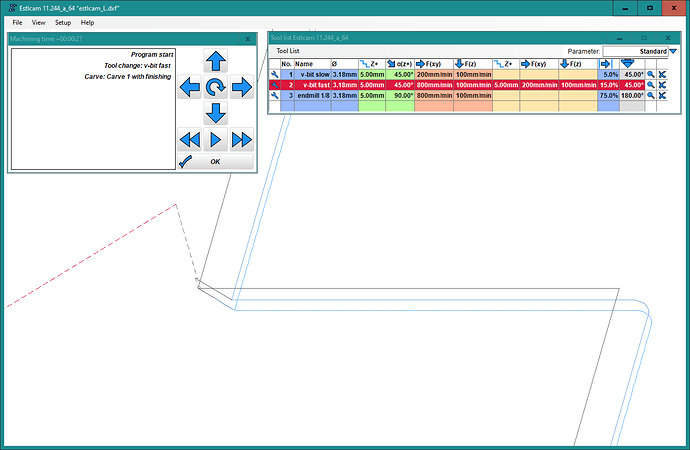

If the maximum carve width is reduced such that no pocketing occurs, then the perimeter is considered a ‘carve’ and not a pocket, and the result is two curves that are offset in Z by exactly 0.5 mm.

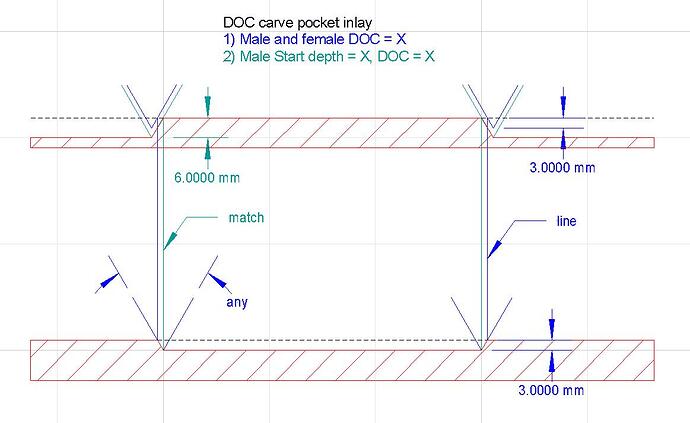

I thought I might “simulate” a finishing pass by raising the start level above the workpiece and increase the depth by the same amount. This would produce the bottom of the pockets at the same level, but all the perimeters of the pockets would be offset laterally due to the angle of the bit, and the carves would be raised in Z. Unfortunately, the start level cannot be less than zero. It might be possible to “trick” the machine with some G92 business but this quickly gets confusing and is very prone to mistakes.

Independent from achieving a finishing pass, due to an “blunt” imperfect tool, I am wanting to fudge the piece widths using the depth limit and start level, but start level can’t be negative (above workpiece).

So to summarize, the request is:

- Finishing allowance should be treated as a horizontal allowance (even if it is implemented as a vertical offset for carves).

- Finishing allowance should apply to pockets generated by carve operations, as well as carves

a. Pockets should be offset by finishing allowance (offset radially and full depth)

b. Finishing pass should trace perimeters of pockets, not just carves - Finishing pass should respect finishing feed rates

- Carves should respect climb / conventional settings

- (Request) would like to have negative starting depths available (above workpiece) to allow fine-tuning the width relative to the depth. This helps correct the last bit of error when preparing inlays.

Thank you.