I’m guessing it’s not unusual to make thru cuts with a straight sided bit on material that’s thicker than the length of the bit’s cutting edge(i.e. 3/4" material, .625" cutting edge). If you want a finishing pass with Estlcam will it step down in the same steps the original cut was made or should you not use a finishing pass in this situation? Or should you not be cutting material thicker than the cutter length?

Finishing pass will use the depth of cut you give it. It doesn’t have to be full depth.

Are you limited to one depth? If so I guess I’m better off without a finishing pass if the cutting edge is smaller than the material thickness. I thought I might be able to step it down like the initial passes.

I’ve been playing with foam and even dry running some things which answers a lot of questions. I finally hooked up my LCD and famous last words but I think I’m ready for some hard stuff. ![]()

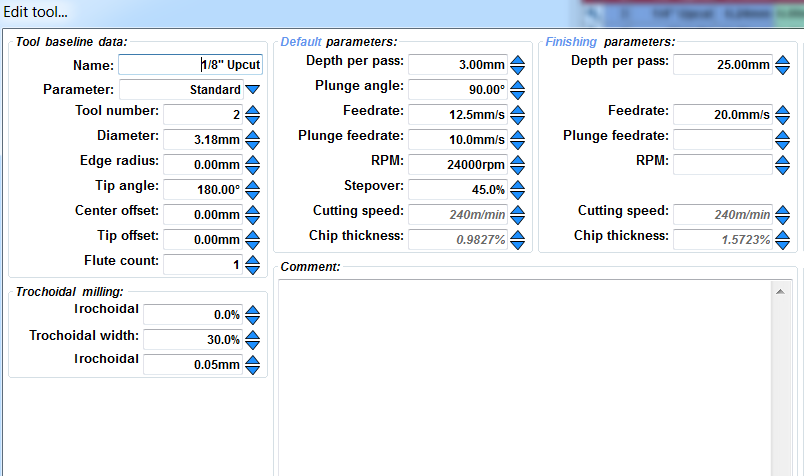

The step down can be the same or different. Each tool effectively has two modes, one for normal and one for finishing, where step down and feedrate can be specified separately. These are the yellow boxes in the tool list.

Further to Jamie’s comment, the finishing pass will use the same DOC and feedrate if no finishing pass info is input in the tool settings. You can specify a finishing pass DOC and feedrate if you desire. Typically (in my experience) you would use about 1/3 of the tool diameter as the finishing pass. Feedrate can be sped up as well (I use 20mm/s with my 3mm endmills).

Thanks for the input guys!

Just so I’m clear: Say I’m cutting the outline of a part and only want to use one tool. Am I correct in thinking that if I specify a finishing pass the allowance will be made in the X,Y direction and the Z will step down as specified for that tool, both during the roughing and finish passes?

Correct. It will follow the default tool parameters unless you specify different numbers in the finishing parameters. The finishing parameters are by default empty so you would have to put those in yourself.

Thanks! It’s taken a while and I wouldn’t exactly call it love yet but I’m gradually coming to terms with Estlcam and learning how to get what I need done. I cut some pieces yesterday and other than forgetting to add holding tabs the first time through  they came out OK.

they came out OK.

I’m by no means an expert. This CAD/CAM thing was all new to me when I started and that’s the program I learned first so I feel fairly confident with it after the issues I’ve worked through. Fusion 360 is very intimidating for me.

I’m by no means an expert. This CAD/CAM thing was all new to me when I started and that’s the program I learned first so I feel fairly confident with it after the issues I’ve worked through. Fusion 360 is very intimidating for me.

I know exactly what you mean. I learned some CAD/CAM ~2 0 years ago when a friend let me use a CNC mill in his shop to make some bike parts. It was a pricy program, ~$5K 20 years ago but so intuitive it was pretty easy to learn and the CAM was easy. I’m still trying to find a CAD I’m comfortable with. I think what I’d really like is something between TinkerCad and Fusion. Fusion is likely far more capable than my needs but at times it seems that capability can complicate doing simple things.

So far everything I’ve made has been with Inkscape and ESTLCAM.

Fusion 360 is surprisingly easy once you get past the initial cliff in the learning curve (more like mountain range). Right now, I’m only using it for creating the sketches necessary to cut parts on the CNC or to extrude sketches into 3D parts for the printer. I have not yet moved into the machining and tool-pathing it offers.

I struggled for a long time with creating a sketch that I could export as “cut-ready”, as my sketches were always boxy, and I’d later modify the 3D object to best suit my needs. I know better now, and design the sketch the way I want it before extruding since I now know what all of the toolbar icons do when working in “flatland” as I call it.

I’ve been thinking about putting together a series of very simple “how-to” videos in Fusion that show how to get a shape you want from your head into Fusion, and out into Estlcam from there, ready to cut.

My guess is you’d have no lack of viewers. I tend to feel like Sisyphus trying to climb the Fusion 360 hill. ![]()