Hi, i followed the guides from the website and after i decided to design my own stuff from fusion 360 and try estlcam. I have a 1/8 single flute (5pcs Tungsten Carbide End Mill… https://www.amazon.ca/dp/B07D6ZT8KD?ref=ppx_pop_mob_ap_share). I am still learning the software but can someone point me in the right direction for this problem? I am using pine and i basically opened my logo in estlcam and selected engraving with the basic settings i took from the website i can link them if you need it. Thanks

The fuzzies sanding will help need alittle more explanation on the others goin GB in or o iij t and setting you used screenshots if opsable

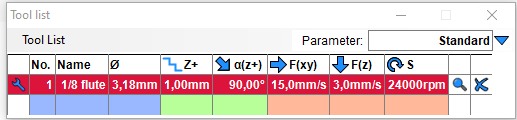

Thanks for the help, here are my tool settings. What do you mean by ‘goin GB in or o iij t’.

android helped with that

are you using lead in ? If is so try it with out and use plunge angle instead

Sorry i am new to all this, lead in? My plunge angle is 90 degres right now, so changing that could help? what angle do you recommend?

What it is doing wrong exactly?

You feeds.look good

What kind of.cut are you doing

I selected engraving in estlcam, i just want to get rid of those wood pieces.

Use a down cut mill or sand

Ok this is a bit type?

Pine tears out with an upcut bit because its grain structure is is large. Sanding the top can assist with the tear out.

Not sure if you got your material thickness correct or dimensions for cutting correct to complete the cutout.

Also, not sure about the dragging, but double check your clearance settings in EstlCAM.

Yes, a downcut spiral bit. A downcut spiral will have a downward shearing action at the cutting edge, this makes for a cleaner top surface, however if you cut very deep it will tend to pack the chips into the cut.

The bit you used is an upcut spiral bit, which has an upward shearing action at the cutting edge. This tends to lift top surface fibers and leave the “fuzziness”. This will probably clean up pretty easily with a little sanding though.

Yes it is a type of cutter it pushes chips down not up and will give a cleaner upper surface

I use an upcut with a .6mm finishing pass in wood and get very very little fuzzy, and can almost brush it off with my hand.

I usually use poplar to get around the fizzy much less but the finish passes help immensely