Hello , do you have any frame with only X and Y axis . i do not need Z axis moving.

Im looking at building 24×24 inches or 30×30 inches

LowRider would be tricky to remove Z travel due to the overall design. Locking/eliminating Z travel would be easier on the Primo design but would still require some effort.

The ZenXY does not move in Z

Either the Primo or LowRider could be set up not to move in Z by replacing the motor, leadscrew and Z nutset with a fixed piece. It wouldn’t be too difficult to print a piece that mounts to a NEMA17 motor mount and has a fixed length rod to a dummy nut.

In the case of the LR3, the whole thing could probably just be eliminated, and have the machine ride on the bottom of the YZ plate opening.

Of course, just because a machine can move in Z doesn’t mean that it has to. If your Gcode oonly moves in X/Y then that’s what the machine will do, and it will just stay where you put it in Z.

All this begs the question: what do you intend to achieve with this?

If you’re looking for something easier to build by removing one axis, surely you are asking for more trouble by having to redesign it around fixing the Z axis in place.

I have a lowrider right now , but the Z will go up to safe height then travel to the spot and come down .

I will check out the primo and zenXY to see if it can achieve what i havr in mind.

Dont curse but i want to expand my K40 from 8×12 to at least 24×24

I have a design in my head but im still figuring it out.

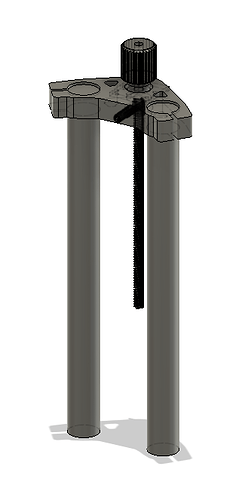

So, answering Dan’s question, you don’t need an active Z axis because you will be running a laser? Will you need a manual Z adjustment, or do you just change the focus of the lens? I run a NEJE laser module on my Primo. For this particular module, I have to manually set the Z height. As an experiment, I designed and printed a 3D printed version of a manual Z axis. The lead screw and the tubing are all 3D printed. I did use a 608 bearing to keep the action of the lead screw smooth, but after using it, that probably wasn’t necessary.

I’m out of town, so I cannot show you a picture of the finished version. It worked well. I abandoned it when I realized that, if I used my normal Z axis, I could set Lightburn to descend with subsequent passes, improving my cutting performance.

If you have any CAD experience, you could modify the MPCNC Primo core so a laser can fixed-mounted to the core.

Ah. Laser cutter.

Someone (Who has slipped my mind right now) has mounted a CO2 laser tube to a Primo. Because the core does not move in Z, this is probably more suitable than a LowRider,

Primo 40w laser build Ah, here’s a thread…

I know it’s been done more than once.

Now, I think that this isn’t a great idea. The Primo’s gantry rails are not enforced as square at power off, and a misalignment could end up as quite the injury risk. That said, if you operate the machine such that the machine must be homed before the laser can power on, it might be safe enough. (Using dual endstop firmware.) The rest is up to your usage case.

If this is intended as a laser only, you could omit the entire Z axis part set. No need for the Z motor, the Z rails or the Z bearings in the core. A simpler core without the provisions could probably be worked out, but for simplicity sake, I’d probably use the Primo core as-is, but maybe print it at lower infill if it’s only going to hold the laser head.

Hi , i have made and successfully been using a co2 on my primo , gives me a large cutting area the a Chinese one will not give you , yes you must respect the power and try too box in as much as possible , biggest challenge was the mirror positioning , but when its done very satisfying

As a resident safety monkey, I have to echo Dan’s warnings, and express again that what you do in the confines of your own property is, in fact, your own liability business, but running a CO2 laser without a full enclosure is a really, REALLY bad idea. Hell, running a diode laser without an enclosure is risky, but those are at least mounted to the gantry, and can be reasonably assumed to be pointing down.

But again, just being the duly diligent safety monkey.

I have a rambo board with my lowrider and not sure about the name of the board on the k40 but it runs whisperer . my plan is to keep the tube in the metal frame and build an enclosure around the whole thing

I have aligned and took it apart just to get practice with alignment . i am building an enclosure around it

Thank you . i will be building an enclosure

Let me know how you get on and good luck