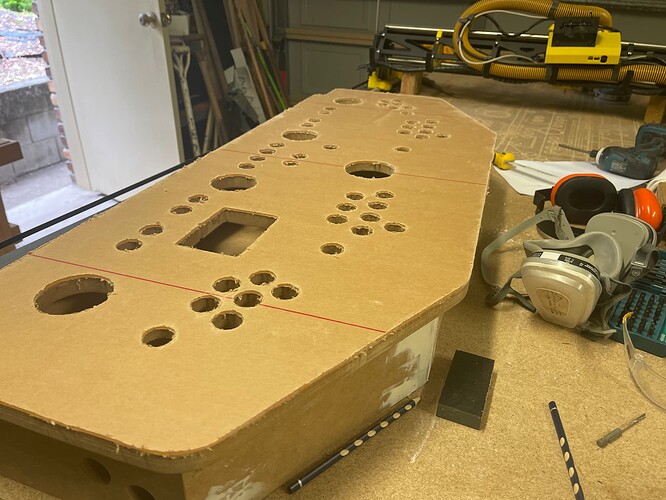

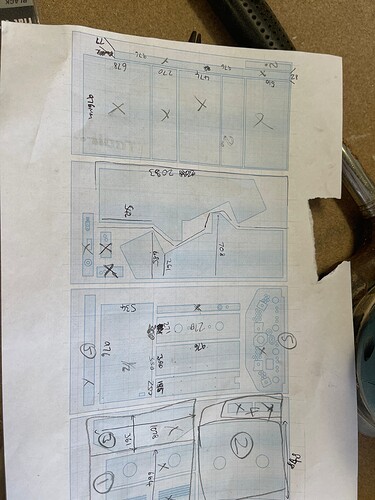

Progressing well so far with cutting all the bits out. As I didn’t go full sheet size I am needing to think through the cuts before getting into it. But has been fun so far.

Today I did the largest / longest cut which is the controller board @ 3 hours but time. Everything went superb except for literally the last tidy up cut around the outside where “something happened” I’m not sure what and the LowRider started cutting into the panel!

Anyway, I wcould just cut again, but thinking it would make sense to try and repair it and up my woodworking skills.

My thought is to recut the top corner section with the LowRider on a fresh piece and then hand cut that same piece off the control panel. Not sure yet how I would stick them together nicely. Also needs to be a perfect fit as there will be a Perspex piece on top of the control panel that matches the MDF.

Progress shots:

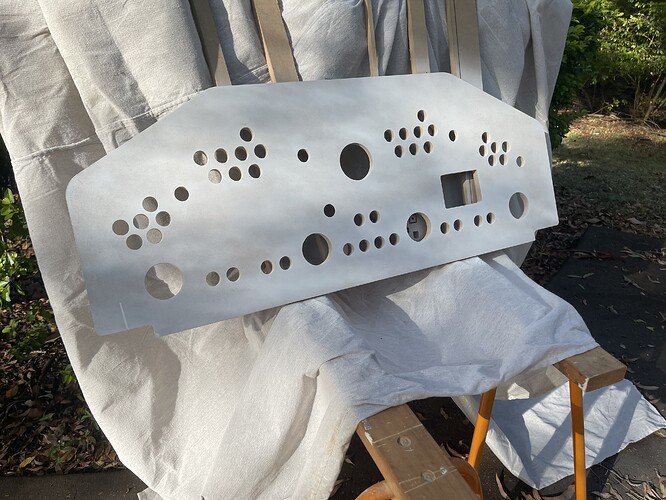

What the bad section looks like (around edges and cut in)

What it is should look like (this is the opposite side)

Any advice would be greatly appreciated!