Question for those of you with LowRiders with “full sheet” 4’x8’ usable areas. How often do you actually need to work with a full sheet? If space were a premium, would you still try to squeeze in a table that size, or would you go for something smaller?

Hi Heath, I’m in North Louisiana. Where are you located?

So here’s an answer to your question but understand I haven’t built mine yet. I expect I’ll need over 8’ in length for furniture building so I’m building a machine that is 2’ x 8’ I would love the 4’x8’ but real estate in my shop just can’t do that. If you are using a lot of plywood to cut out, there is another machine https://www.maslowcnc.com/ that lets you cut 4’ x 8’ sheets of plywood out. The thing making this really special is it cuts the wood on edge. Visit the page and you’ll see why this is cool. The Low Rider and that together make a sweet shop for signage etc.

Hey, Mike, I’m in the Natchitoches area. What part of North Louisiana are you in?

I’ve seen the Manslow and it is rather interesting! Honestly, I don’t even know what I’ll be doing with my CNC. I know I’m going about it backwards. I guess I’m just wondering how many casual hobbyists woodworkers have a real use for a full 4’x8’ CNC and how many thought it would be a great idea to make one that size and then ended up not needing it.

My shop is small - 12’x24’ - and space is at a premium. I think I could fit in a full sheet CNC, but I would have to spend some work and time reconfiguring the entire shop including moving built-in cabinets and getting rid of some other tools. I never use my jointer or my RAS so those are easy things to move to storage until I have more room.

Since you’re just starting out, build a mpcnc. If you decide it’s too small, you can use it to make the lowrider parts, and then cannibalize the electronics. If you go whole hog and build it anyway, use it for the out feed table for your saw. That’s how mine is set up now. So far the biggest parts I’ve cut on mine could have been cut with a 4X4 foot cut area lowrider. A table that can cut a 4X8 sheet will be about 5X9, and you’ll need some room to get to the back sides, unless you’re a masochist like me, and only leave 6 inches of room. I can stand on my table though, so that helps. I am planning on extending the shop though.

Homer, in Claiborne Parish. Love going to Nac to visit. Almost moved there to teach at NSU. I think it depends on what you want to make. Me, I’m hoping to build Victorian bedroom furniture so at first I thought big is exactly what I needed. After thinking about it what I needed is about 2’ x 8’ to carve the posts. I plan on veneering the plywood for the head and foot boards so mostly an 4 x 8 would be more for cutting large panels out and a variety of parts for dresser drawers and the like. I decided to use a Maslow for the flat cut parts and the Low Rider for 3D relief carving. Less wear and tear on the LR plus I can dedicate it more to intricate carving which takes a lot of time to do. The mas does the mass production work. That means making money instead of spending it and, I can do it all by myself.

I guess what I’m saying is determine what you want to build first and then choose the right set up for your needs. I don’t think very many use the 4’ x 8’ unless they make big items. And bigger items mean a bigger possibility to having errors too. I agree with Barry. To start out, the MPCNC is probably the best way to go until you decide you need something bigger. Stay in touch. I’m saving up to build my shop (16x24) and put these and my other tools in. probably next year sometime.

Stay

I don’t own and have never used a maslow, but I think they have trouble in the upper corners, and they have trouble doing too much cutting or carving, since the reference surface is the cutting surface. I wouldn’t mind using one though, it seems like a very clever idea.

I have a 4’x3’ work area low rider. I intended to have the table extendable to 8’. It’s at the end of the garage, so I was hoping to just move the car and build up an extension to the table. The biggest thing I’ve made is about 2’x3’. I have a shed that is 10’x16’ for my woodworking, and I have a few feet around the cars in my garage. So I’d consider my space also at a premium.

IMHO, A full sheet is a desirable size because:

- What’s the point of going bigger? It’s not easy to find material bigger than 4’x8’.

- If you can lay out a big job, then you don’t have to break down your sheet. Cabinet makers would really appreciate this, if they can batch cabinet carcasses from full sized material while they are working on other details nearby.

Compared to other CNC machines, the LR is easier to change size. Even changing from an MPCNC to a LR is pretty easy, once you’ve used the MPCNC. That’s what I did. Now, I think something like a 24"-30"x36" would be about perfect for a multitude of woodworking for even a serious enthusiast. I’ll probably shrink mine someday, but I have higher priorities ATM. 24"x36" is right in the gray area between LR and MPCNC, where the LR still has an advantage. Something like 16"x16" or even with one dimension closer to 24" would also be a ton of fun, and would be right in the wheelhouse of an MPCNC. You can also do goofy tricks to hang some of the material out the side, or work on pieces that are larger, even though the tool can’t reach the whole thing.

Because of the flexibility though, I wouldn’t worry too much about it. Steppers, controllers, a lot of the hardware, is all reusable. Make a machine that fits into your shop, learn the ins and outs, and then decide how much space it’s worth to you.

As I mentioned, I know I’m going about it backwards. Currently, the goal is not “what I’m going to make” but to “build a CNC” and play around with it. I’m too far along to change course from the LowRider2 to the MPCNC at this point.

Do you mind posting some pics of your setup? I’m trying to visualize how the side rails and belts and all would work with the LowRider doubling as the outfeed table. I’ve been looking at the Paulk Workbench and I’m putting serious thought into rebuilding my table saw stand and outfeed table and incorporating a lot of his ideas into something similar to his “Total Station.”

Funny you mention Ron…

I have one of those little funky flip top outfeed stands that go between the saw and the cnc for shorter stuff, and for floppy stuff, but the cnc is about a half inch shorter than the saw top.

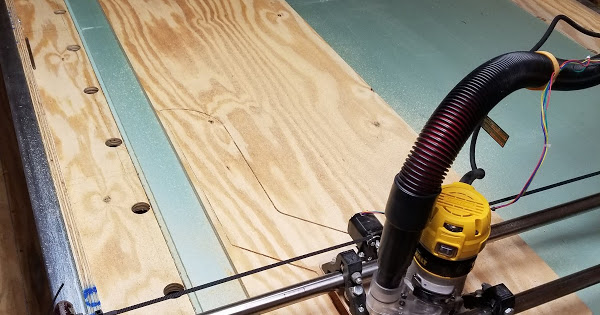

Here’s a side-ish shot before the LR2 conversion, just after I made my new saw base.

I was actually studying one of your pictures earlier, but it didn’t have the table saw in it. Do the side rails ever get in the way when using it as an outfeed table?

As much as I don’t want to change direction, I think I need to. Despite my attraction to the LowRider, I do think the MPCNC makes more sense for me at this time. If I move my RAS to storage (I love my SawSmith RAS and can’t just get rid of it even if I seldom use it), eliminate the flip-top cart with my miter saw and planer, I can repurpose my current out feed table/workbench for the MPCNC stand. Then build a new Paulk “Total Station” inspired workbench/outfeed table/router table. My three ShopSmiths will still have a home and I won’t have to move my built in cabinets.

Love this table design! I too am looking to use aluminum rails on the sides with the same kind of spacing between spoil board, rails, and lip. Do you have plans for it up anywhere?

Not really. It’s based off a Paulk workbench, just a touch bigger so it’s about 6 feet wide when the two sides are bolted together. Here’s a link to my photo album, there are a couple pics of the plans I started with. I don’t post them because I changed things mid way, but should be a good starting point for you.

I just received all my parts but need to build the table. Mine will be 3’ x 6’.