I am wondering what boards do i need to use GRBL I don’t know much about it. what boards do I need to use it to support cnc router

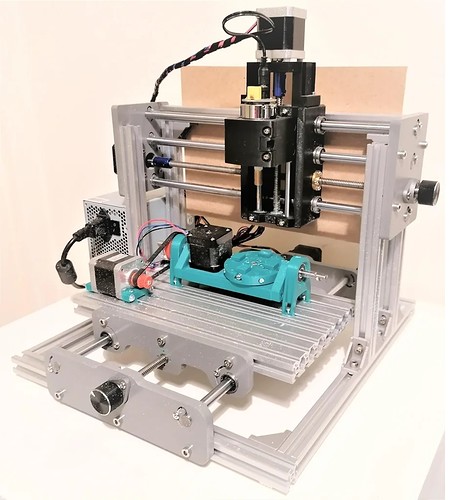

There are several boards you could use, perhaps the easiest would be an Arduino Uno fitted with a cnc shield, this will also be the cheapest option and will perform all the tasks asked of it in a cnc router. Arduinoclub offer several grbl boards, some specifically for use with EstlCam software, some for plain vanilla GRBL. How about something like this offering from Banggood, it seems to have everything you need for cnc work without having loads of superfluous components. There are many other more advanced boards but they tend to come with lots of unusable functions like heaters,thermisters and fans because they were primarily designed for use in 3D Printers, A RAMBO board would be a good example of this. There are also 32bit boards that are available that run a ported version of GRBL that bring wifi capability to your workflow at the expense of moving away from the mainstream GRBL. There are many others also.

A couple of us have this now. I haven’t really had the chance to play with it much yet though.

I have just hooked up a two channel variantof this from the same developer on tindie for my ZenXY table. First impressions are very good. Using GRBL_ESP is pretty amazing. It basically does the work of the Rambo + Octoprint in a single, super compact package.

Bart also has a cheaper grbl controller for the MPCNC.

does arduino mega 2560 control board support “GRBL_ESP” trying to figure out a way to compile the firmware without using visual studio, i get errors.

Im new to GRBL, but I believe you can compile versions of GRBL for arduino, OR you can find GRBL firmware for the ESP series controllers, one FW version of which is GRBL_ESP.

BOTH can be programmed via the Arduino IDE software (make sure you choose the right board in the IDE, and the right firmware files for the board you intend)

grbl is not the same as grbl_esp. grbl_esp was rewritten to basically respond just like grbl (it should have the same protocol as grbl) but is designed for the esp32 chip, which is a dual-core, much faster, wifi and bluetooth enabled chip for $5. The bart dring boards are of great quality (look up Bart, if anyone is curious, he has been in the CNC for a long time and does not do it for the money).

The Arduino CNC shield also works just fine though. You aren’t doing anything computationally expensive controlling a CNC machine. You don’t need a faster chip with wifi if you don’t want one.

what all would I need for an arduino cnc, I can’t find much info online?

This Uno and cncshield package has everything you need to control a cnc machine with either Marlin or GRBL and at around $12 delivered you wont find a better value alternative.

thanks

how can i make that 5 axis?

That one you can’t. It’s hardware is limited to 3 axis, and one additional “cloned” axis (has to match one of the first 3).

This looks like the board I’m using on my Burly. I’m running grbl 1.1 (j I think…). One driver per axis, X and Y axes with serial wiring, single endstops on all axes (Z homes “up”) plus a Z probe, and PWM spindle speed. I’m happy to answer any questions about my setup. I can’t do auto-squaring but haven’t missed that feature at all.

Perhaps you would be better off explaining exactly what capabilities you are looking for because clearly you are not just looking for ‘an arduino cnc’

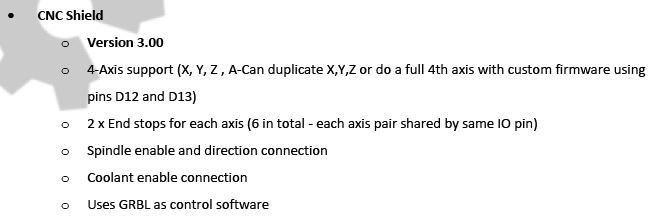

Actually it can do a full 4th axis with custom firmware per the CNC shield documentation:

That custom code 4th axis may be at the expense of whatever the default uses for D12 and D13 are. I don’t recall off the top of my head, but they may be spindle enable and spindle direction.

I am doing lowrider with 5 motors nema 23. Like tom myers. Here is what i’ve found what do you think. they are selling it as a 3d printer board but I think it will work with drivers.

https://www.amazon.com/dp/B07Q5R6YSK/?coliid=I1FSN0YI8HA0G1&colid=1JIKKBREKO9M2&psc=1&ref_=lv_ov_lig_dp_it

A lowrider with 5 motors will work with the Uno and cnc shield item I suggested. The Lowrider with 5 motors is NOT a 5 axis machine, this is a DiY 5 axis machine

A Lowrider is a 3 axis machine with 2 axis using 2 motors (Z and X). These motors can EITHER be wired with each pair of motors series to the same stepper driver, in which case only 3 stepper drivers are required OR each be wired to separate stepper drivers, in which case you will need 5 stepper drivers. If you decide to go for the mega2560 RAMPS board you link (which is out of stock at the site you linked) then you could wire each motor to its own driver, this will give you the ability to set up auto-square your x and z axis’ but this adds significant complication for little benefit (although others may disagree). Perhaps you should take the simpler options first to learn the machine operations before trying to run.

I’m using one of those, works great after some initial teething troubles.

THEY SELL teething rings for that. lol. which one are you using. by the way if i am using auto squaring how would i hook it up, would it be in parellel.