For my LR3, I’m planning on soldering wires onto the tabs of the end-stops, how long should the wires be?

I will be putting female Dupont on the other end, I have those on hand.

I like to approximately match the length of the wires on the motors. This makes the V1 wiring extensions most useful, or whatever wiring solution you use to extend the wiring.

For the Z stops, the stops are about 130mm away from the base of the motors, so somewhere between 90mm and 150mm longer than the wiring for your Z motors is pretty reasonable. On the LR3, the Z stop wiring goes down past the Y drive motors and over to the Z motor.

The Y stops are actually pretty close to the Y motors, so about the same length is probably good, give or take about 25mm. The X drive is also a similar distance to the X endstop, so it’s more or less the same there.

If you really want to line it up, go to the slightly longer side of things, and trim the wire before you attach a connector on the end of it, I guess.

For the near side of the Y and Z wiring, the motor wires are actually already longer than you need to reach the provisioned control board box, and could be trimmed shorter.

For the X, Y2 and Z2 drives, the motor wires won’t be long enough and will need an extension. This can be in the form of the V1 wiring kit, or whatever kind of 6 conductor M-F Dupont extension you want to use.

Thank you for the details response. I truly appreciate it.

I’m stuck on the top of page 40 it says, “Insert the Y drive. It goes in with a 90 degree twist. Should be plenty of room …”

Does anyone has a video of close up of this step. Thank you very much

It shouldn’t be that difficult.

The Y drive assembly is the printed part with the motor installed (Since you can’t get to the screws with it in the plate) The rollers are too wide to fit into the plate without that twist…

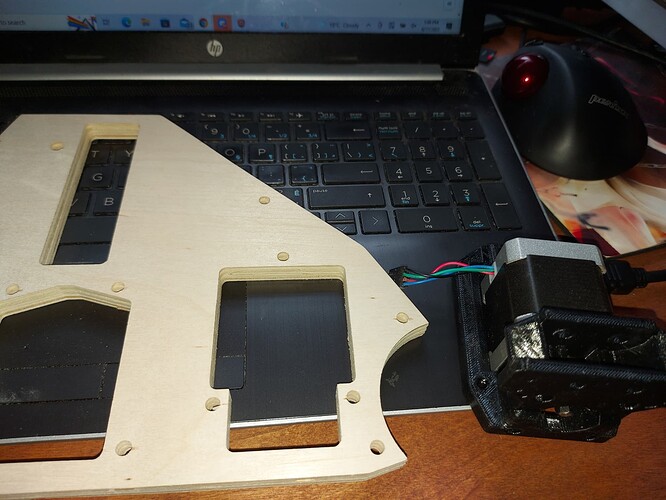

I happen to have a spare YZ plate and a spare Y drive, with an old motor…

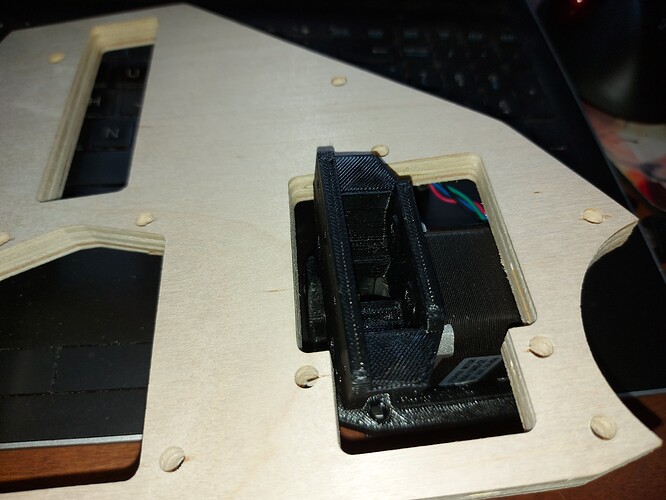

This is the 90° twist that the instructions mention, to get the roller part through the plate

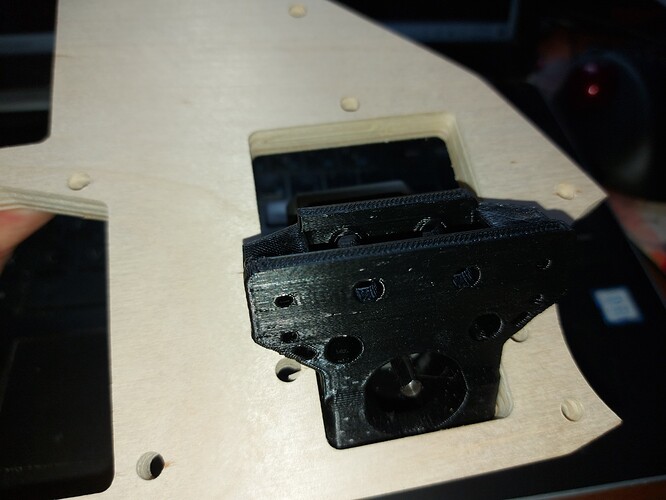

When you first straighten it, the motor will block the access a bit, so lean the part back, and fit it to the bottom of the opening. This is also where you will pull the wire through. This is also where you will fit the Z endstop wire, there are relief cutouts in the Y drive for the Z stop wire.

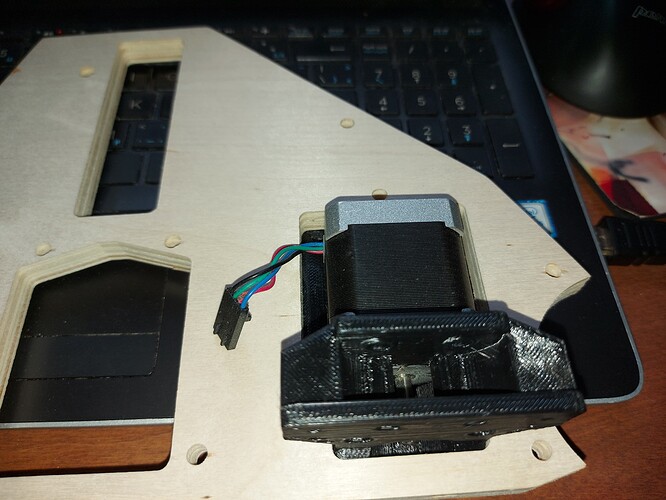

I recommend this orientation for the Y drive motor wires, and then collect them together under the Z drive.

Thank you for the photos a speed detailed reply, that worked out great.