My access to my MPCNC is limited so I am anxious to maximize my time on it when I can. I would really like to get in to inlays and carving. I’ve been trying to do tool changes to save myself cutting time, but no real luck. I don’t have end stops. Other videos I’ve seen said run each tool as a separate job. I don’t know how to make the carve pocketing tool a separate job in Estlcam though.

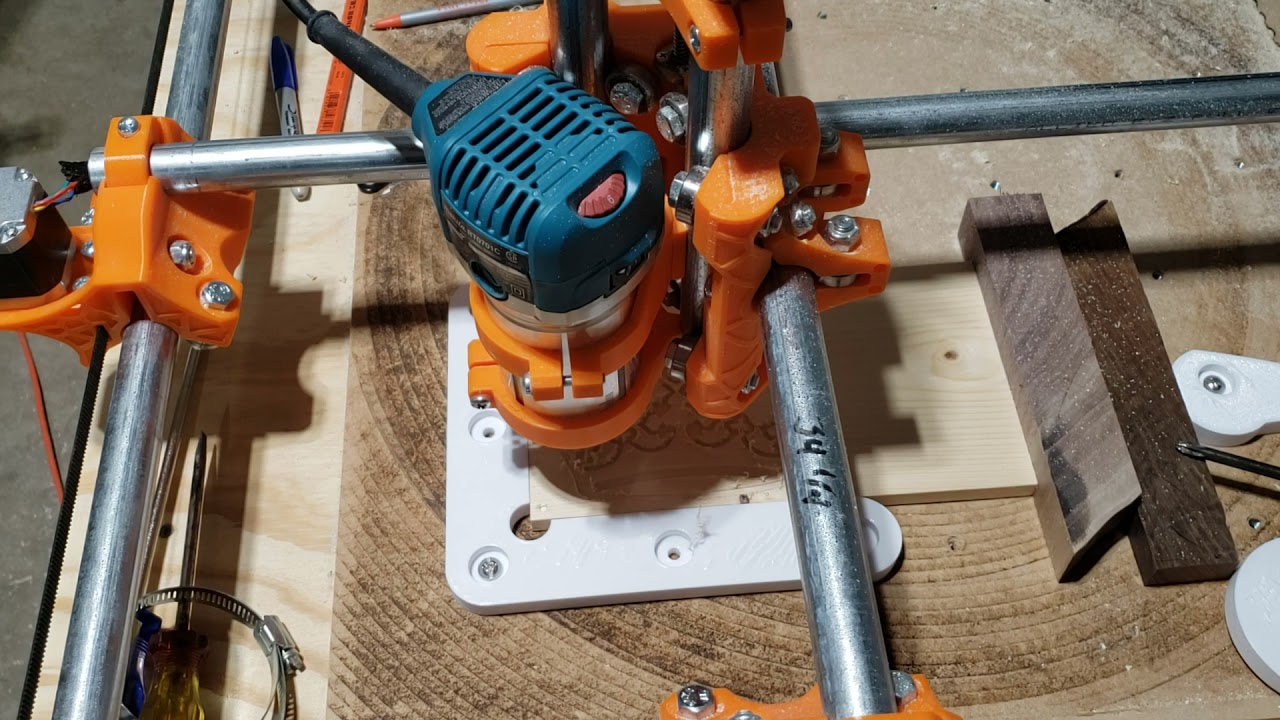

Before I get into the description, here are the details of my machine:

24"x24" work area, 3.25" Z-height

12V Einsy Rambo with serial configuration

Makita Router set to maximum speed

Single Flute Upcut bit from the V1 store

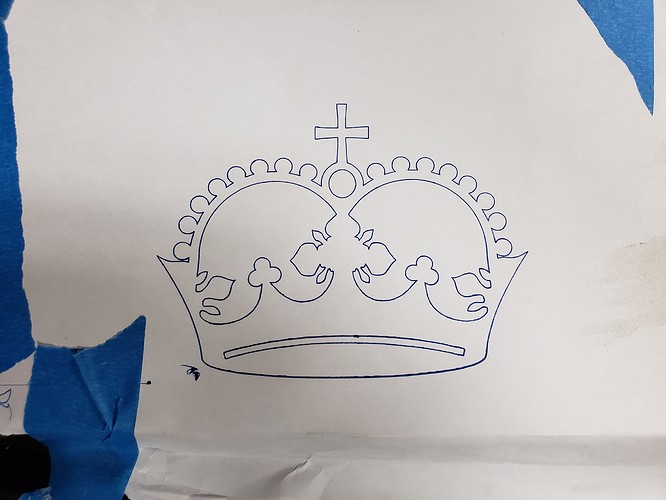

As a test, I ran the 12 mm/s Crown test file. I know it’s traditionally done with the pen, but I didn’t have a pen. I thought it cut it out fine. It returned home after the job was finished. I lowered the Z axis back to 0 and hit print again without touching anything else. It seemed fine this time around. After it returned to home, I lowered the Z-axis to -1mm and then hit print again.

Here’s what I noticed on the 2nd cut:

The Y-axis looks shifted. I’m not even sure if running the same file multiple times is a valid test, but I have seen similar issues before. I had assumed it was because I had speeds to fast or too much cut, but that shouldn’t be the case here. It is pine wood that I’m cutting here.

Here’s a video of the 2nd pass in case that shows anything.

The grub screws seem tight. The belts seem tight. Things seem to be square, but I’m obviously missing something. Ultimately I’d like to get to carving things and it would be really useful to switch tools, but that seems a long way off if I can’t get the same job to print twice in the same spot.

Thanks in advance for any help.