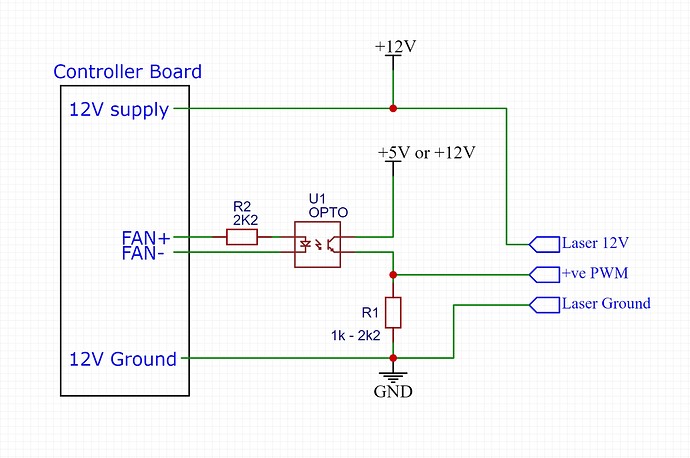

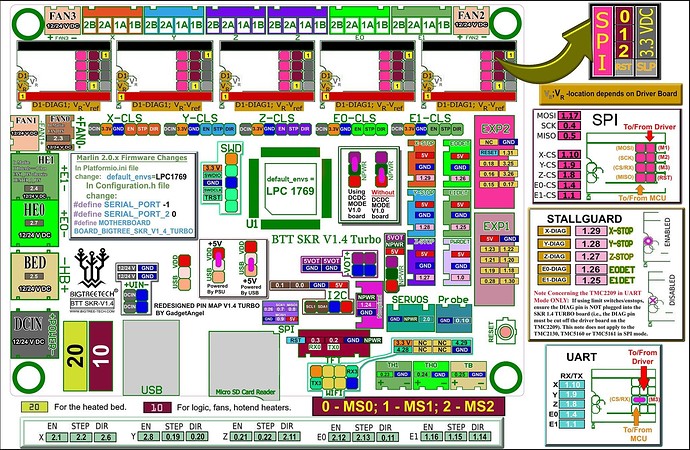

I have a 8 watt output laser that I can successfully turn on and off with the TFT35 Spindle interface, but it does nothing in the laser interface (replaced fan interface). Below are the changes I made in Marlin compiling for a BTT SKR 1.4 Turbo. M106 Sxxx (ive tried different number 0-255) does nothing. What am I missing? +12v and GND are connected to Fan 0 and the PWM pin is connected to P1.24 of the neopixel connector.

in Configuration_adv.h

#define LASER_FEATURE

#if EITHER(SPINDLE_FEATURE, LASER_FEATURE)

#define SPINDLE_LASER_ACTIVE_HIGH true // Set to “true” if the on/off function is active HIGH

#define SPINDLE_LASER_ENA_PIN P2_03 // Fan 0 pin for +12v amd GND for power and enable/disable

#define SPINDLE_LASER_PWM true // Set to “true” if your controller supports setting the speed/power

#define SPINDLE_LASER_PWM_PIN P1_24 // Neopixel data pin for +5v PWM

#define SPINDLE_LASER_PWM_INVERT false // Set to “true” if the speed/power goes up when you want it to go slower

#define SPINDLE_LASER_POWERUP_DELAY 1000 // (ms) Delay to allow the spindle/laser to come up to speed/power

#define SPINDLE_LASER_POWERDOWN_DELAY 1000 // (ms) Delay to allow the spindle to stop

in pins_BTT_SKR_common.h

#ifndef FAN_PIN

#define FAN_PIN P2_05 // move fan 0 pin P2_03 to bed bin

in pins_BTT_SKR_V1_4.h

#ifndef NEOPIXEL_PIN

#define NEOPIXEL_PIN P2_05 // move neopixel pin P1_24 to bed pin

#endif

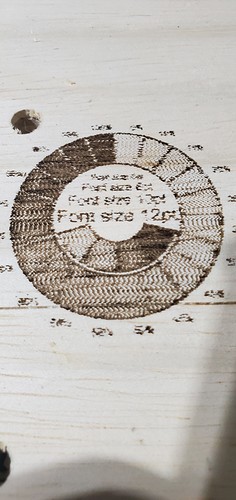

Update: M3 and M5 work, but the Sxxx feature doesn’t change the intensity.

so is that a typo?

so is that a typo?