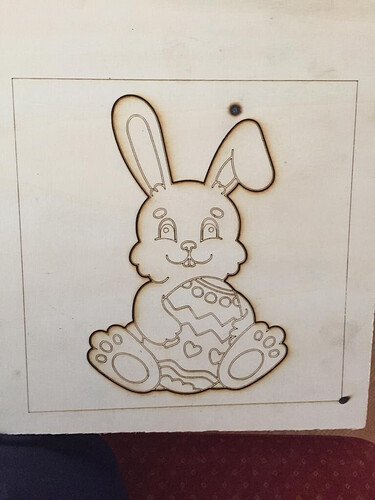

Are you asking what to put under the work?

Whats material is the best under the wood? What underground?

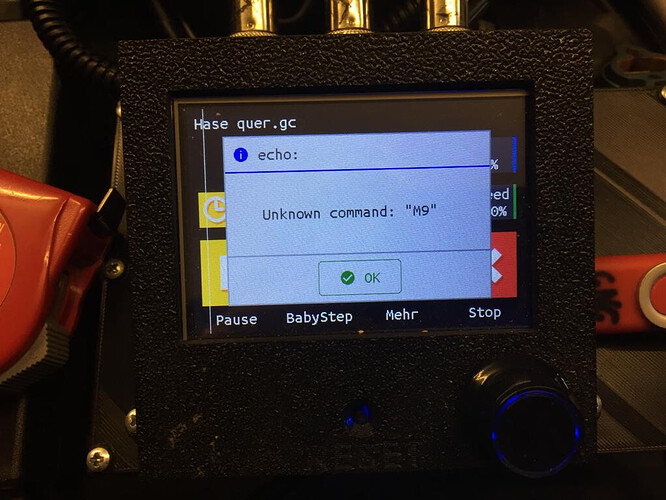

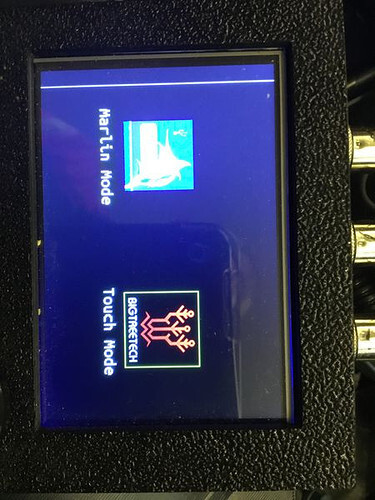

In the marlyn-mode i only get these answers. What’s the problem? Do you know it?

While working in ligtburn i had a work-break but i don’t know why. The second one was no problem.

Waht’s better: slow speed with high power - or - high speed with less power by lasercutting with 4mm wood.

Many greetings

Grassy

Marlin mode uses the two gray cables. You might have them backwards or swapped. They are harmless to plug in backwards.

Leider habe ich diese zwei Kabeln nicht, daher werde ich vermutlich die Fehlermeldung erhalten. Gibt es eventuell auch eine andere Möglichkeit, dies zu umgehen?

Unfortunately, I don’t have these two cables, so I’ll probably get the error message. Is there any other way to circumvent this?

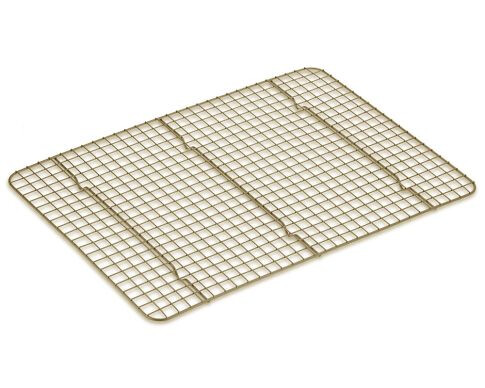

For cutting, I place a piece of sheet steel to protect my spoil board. On top of that, I put a piece of aluminum honeycomb I purchased off Amazon like this, but anything that lifts the work even a few mm off the surface will work. I’ve seen cooling racks used:

But what did NOT work for me was metal mesh from the hardware store like this:

There was too much flat metal against the back of my wood, leading to areas that were not cut through.

Note I purchased my honeycomb without a frame due to cost, but I wish I’d spent more and got one with a frame. With use, I’m finding the edges are tending to curl up, so I have to place weights on the mesh to keep it flat.

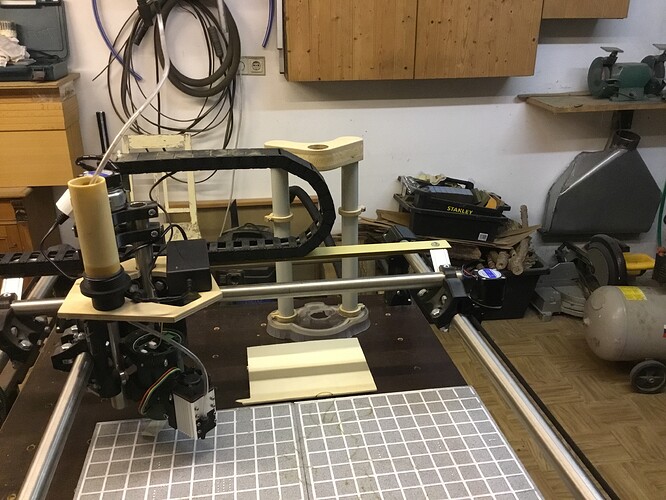

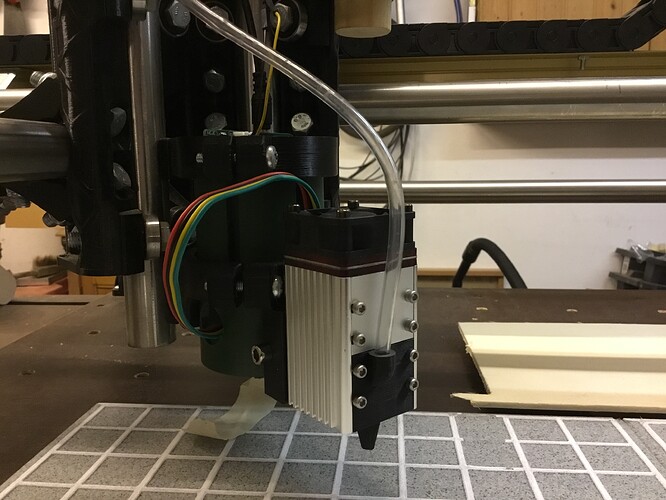

If you are going to be doing a significant amount of cutting, air assist is highly recommended. David (@dkj4linux) has provided the STLs to 3D print air assist nozzles for the NEJE 30W and 40W modules. See his post here. For pumping the air, aquarium pumps are common. You don’t need a large flow of air.

Waht’s better: slow speed with high power - or - high speed with less power by lasercutting with 4mm wood.

I don’t know what is better. Most of my information was acquired from YouTube, and the information on single slow passes vs. multiple passes is conflicting. This is my personal recipe:

If the job takes less than 20 minutes, I cut with 100% power. If it is longer, then I use 90% power. This is to extend the lifespan of the laser. If the cutting speed drops below 3mm/s (180mm/min), then I do multiple passes. Note LightBurn has a setting that moves the laser module down with each pass, giving some benefit to faster multiple passes vs. single pass. Moving down moves the laser focus point further into the wood.

![]()

Ich habe bereits 0,5 bar Luftdruck während der Arbeit.

The marlin-mode bereitet mir noch Kopfzerbrechen

I know the issues with the TFT firmware are being looked at, but since I don’t have the SKR board with a TFT, I’ve not really kept up on where they are with respect to a fix. Air assist makes a big difference, so I’m glad to see you have that installed already.