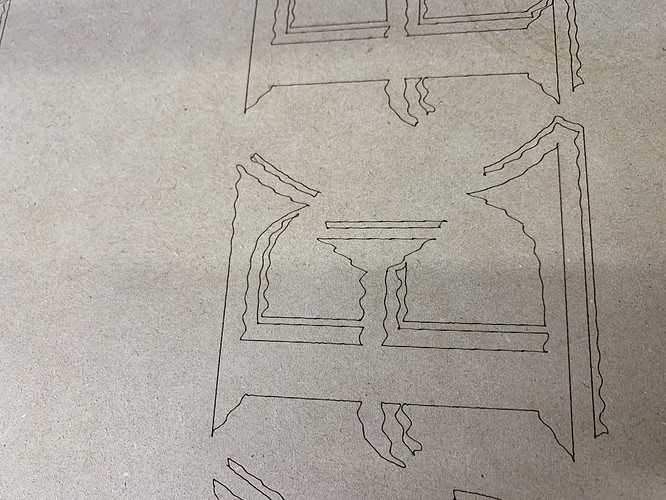

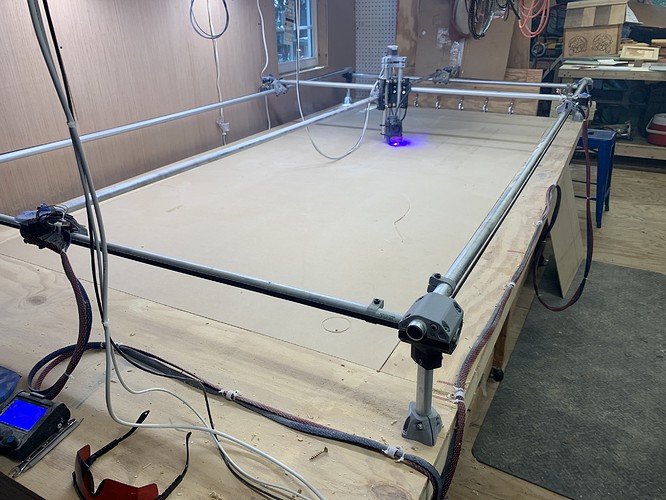

Is there a way to tighten the gantry. I know I made a giant Micmac but thought seens there was going to be no z axis pressure it might be fine. It doesn’t appear to be the x and y giving me problems just the gantry on the movements that require x and y to move together straight and curves seem to be fine.

This is why the Lowrider exists…

At a minimum, you’ll need supports in your X and Y spans.

As above.

The MPCNC was never designed to go that big. You might get away with adding supports along the X and Y rails but if I were you I’d be looking at the Lowrider as an alternative.

Yea, lowrider with an acrylic carriage so you can see the cut would be the way to go.

The advice like, “you should have built a low rider” is right. But I imagine that is pretty frustrating feedback. It is clear there was a lot of effort, energy, and expense in this build. It looks good, but it is very very large.

There are a couple of things you could do to make this work better:

- Make a good test pattern. Something like a few different sized squares and arcs. Something where you can measure a few mm of error as the machine whips around a corner.

- Drop the Z height. I would be curious how much that helps on its own. You have a laser, which is zero load, but there is still a lot of weight in that huge gantry moving around.

- add midspan supports. You might be able to test how effective that would be by just doing a pattern in the middle vs. at a corner.

- make sure you are very square, your motors are moving smoothly, and the bearings are touching. If something is snagging, it will stutter and that will make everything shake.

- reduce the top acceleration and speeds. You have the heaviest gantry on here, even with a laser.

Ultimately, building this out of 1" tubing instead of 3/4" pipe would have been a little help, but this build should have been a low rider. You can still salvage this by cutting this down to 24"x24"x3" and I bet everything will be fine. Fine enough to start building a low rider for this big table. Probably not the news you want to hear, but I guess that going from 1-5 above, you will still end up with sloppy results with a build this big.

I actually have the pieces to make it a low rider. The table use to be a lowrider but I could never get the z axis to work and didn’t use the router portion of it and was converting it to a laser thought mpcnc format might work.

Man, i thought a 2x4 mpcnc was big!

Still, for a laser i don’t think it’s so bad. Like Jeff said, though, try to shorten the z. That laser is WAY below the gantry, and that’s gonna cause it to whip around a little at corners. You might alleviate some of that by turning the acceleration down, too.

Also, hard to tell what the zip ties are holding. Looks like a tool plate mounted behind the laser, so if the laser is screwed to that, good. If it’s the zipties holding it on, well, that can’t be helpful.

After some experimentation I can run it at 8 mm a sec and get good results

The sheer size of this is amazing!