What a beast! Looks great.

This thing is awesome! Makes me want to build one!

In terms of speed, depth of cut what sort of performance are you seeing? Hugely admiring your machine.

I am mostly cutting 3/4" plywood for cabinets at this point. I am using a 1/4" downcut spiral end mill. So far I have used the default feed rate provided for this bit by Fusion 360, 1016mm/min. I have my DOC at 9.525mm (3/8") so the pieces are cut, including tabs, in two passes. No bogging down. No missed steps.

My NEMA 23 plastic parts are not based on stress analysis, etc. They are adaptations of Ryan’s NEMA 17 parts which are based on good analysis. I am still monitoring for rigidity and stress issues.

I am still tweaking my work with a goal of cutting 3/4 plywood in one pass while maintaining dimensional accuracy and limiting wear.

After a long work week I finally got to assemble all of pieces I cut last weekend. I love my Lowrider…

Yo, I was talking to the wife a couple nights ago about recruiting you to help with our cabinets next year. The original plan was to rebuild my lowrider and diy, but that doesn’t make sense with you and your experience right down the street. Go ahead and start thinking about what would make it worth your while.

I am following this thread closely, as I am just about to start building my first Lowrider. The doubled bars to stiffen the gantry seems like a great upgrade. I wonder if I could use 1" aluminum extrusion for the upper bars to keep it light weight for the NEMA17 steppers, though I’m eyeballing the NEMA23s now… I’m building mine to make cabinetry and some other projects, so seeing you do this is exciting for me.

I would suggest building it stock first. You’ll then have firm footing to know what you want to change, and you can spot issues easily.

That’s the plan initially, though I’m very much a tinkerer. I’ll get used to it before I try breaking end mills.

I agree with @jeffeb3. This community can help you with issues during your build or with dialing it in after your build is complete if you start stock. Get to know your machine first and then you will KNOW what upgrades are important to you.

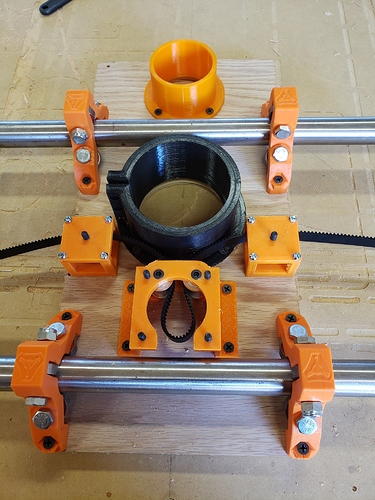

A couple of gantry issues have come up since upgrading to NEMA 23 steppers. The first one is that the X-axis motor hanging off the back of the router plate deflects the rails causing the bit not to be plumb. The second one is that as the bit is drawn along the rails cross-cutting plywood there is a constant torque/release that is more pronounced in the center of the span setting up strong vibrations in the gantry.

I am redesigning my gantry to move the motor between the rails to eliminate the first issue and adding pulley blocks to route the belt so it exits the router plate centered between the rails to eliminate the second issue. Still more design work to finish.

Hey Tom, Looks great.

[And i want your cabinets to replace the beat ones we have now. LOL]

I’m working on a 60"x60"x5" build based off of your upgrades as I have a

stack of NEMA-23 steppers with drivers and want to be able to add

table indexing pins to allow working up to 4’x12’x1" or 5’x10’x1" sheets

of stock.

2 questions.

1: Have you considered adding 1 or 2 pair of pulleys in the ends of the X axis

and run a loop attached at the other side of the router plate instead of the

single belt? [After doubling the steps/mm to compensate of course]

It should effectively double the torque on the X but it will affect accuracy

with non steel-core belts <10mm wide.

2: What’s the chances that the current updated router plate files with the

repositioned stepper and added belt routing pulleys will be added to the

Google Drive folder soon?

Bleeptech.

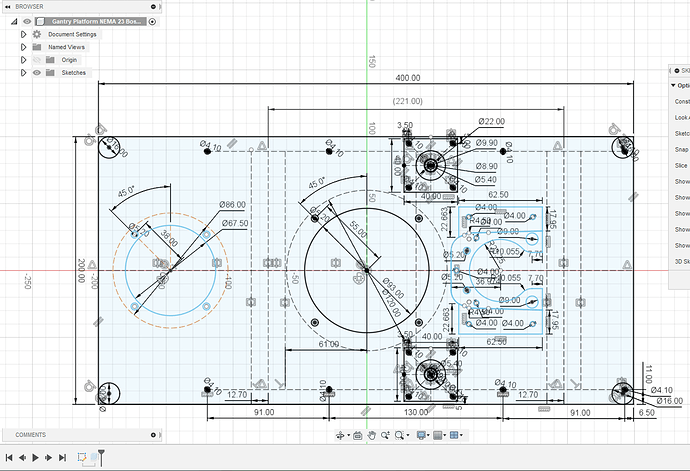

Good morning. I just uploaded DXF files for the router plate and the Y-axis plate. Let me know if you have any issues with the designs.

I am currently finishing my redesign of printed parts to replace GT2 pulleys with HTD 3M pulleys.

Well, I’ve got one oddball issue right off the bat… Dimensioning.

Blender is reading the dimensions as 22 meters between the gantry rails. LibreCad is reporting 22mm and converting to inches seems to be overkill.

I just uploaded STEP files if you can use them

The STEP files gave me ~221mm center to center for the screws closest to

the vacuum port on the pairs of bearing carriers to the right side of the router

which is a much more believable number. [See picture with post #32]

Well Tom, did I guess the magic number and win the Maytag washing machine? ;D

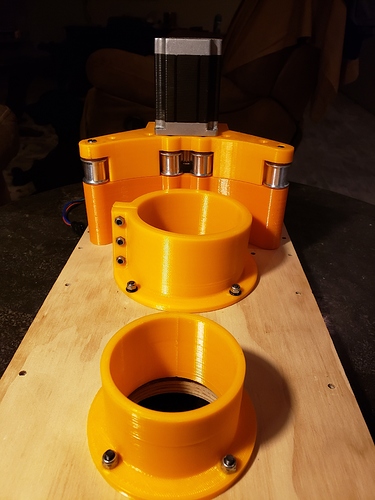

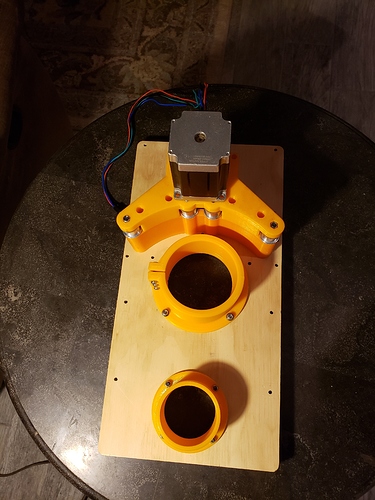

I haven’t been able to work on my Lowrider lately because of my job but I have been studying my first prototype X-axis stepper mount and decided that there were too many things that I didn’t like about it.

So I redesigned it.

I don’t know whether to yell “Go man, Go!” or “Slow down damn it, I’m still trying to build this thing.” LOL