I think You all need to get this song in your ear holes before you go any further, https://youtu.be/-xTGrfs5TXM

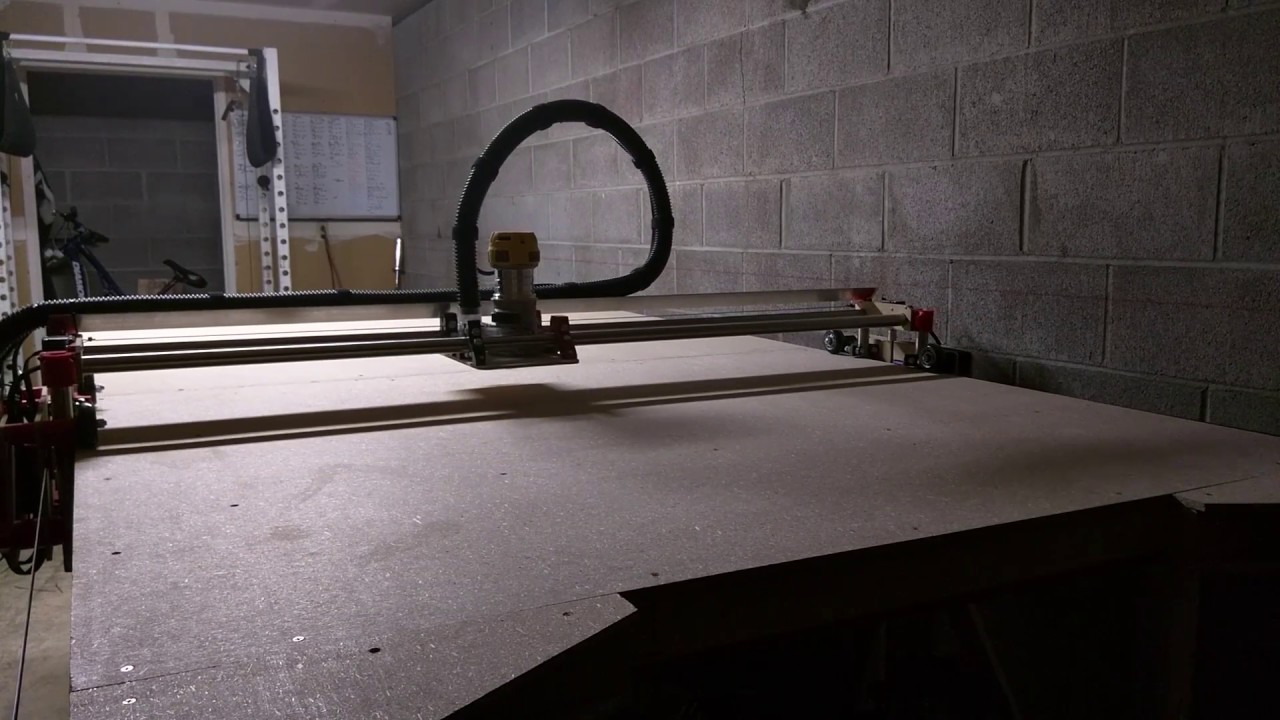

It got its name for a bunch of reasons. First, it is super low profile, like a lowrider that is barely able to get over a speed bump. When you power it down it lowers like it was on hydraulics (not a good feature, but it is there for now). And most importantly, lowriders are custom-built, you can’t buy one complete and call it your own unless you get your hands dirty. You need to build it yourself. When it’s done it may or may not be fast, but it looks good, so cruise it slow and low with pride when you make your cuts.

Okay now here we go. I will fill in details when I’m ready. If mercadolibre was a responsible company, I would have released this a week ago. As it stands, I will wait until I figure out what to do. Gunna have to get a few brave souls to beta test but I will figure that out as the parts start to arrive.

This is by request a full 4’x8’ (or it can go bigger but really??!!) Very loosely based on the Printrbot crawlbot with the CEO Brook Drumm’s permission. As far as I know, I used none of the printrbots parts. I took a look at their pics, made some choices, and designed it all from scratch. If anyone thinks I might be using something of theirs, let me know so I can give them more credit. The crawlbot is a cool machine and a well executed idea.

Price - Just a bit more than the MPCNC. It uses almost all the same parts, I think less printing but requires some CNC’d parts and more belt. Price coming soon. The first run will be limited due to China’s month long vacation. That gives lots of time for a solid beta test.

There are some immediately apparent drawbacks. Visibility of the bit is very minimal, but as most of you know, the sound tells a much better picture anyway. Using the lower friction T8 lead screws means the brass nuts will need to be replaced once in a while and on power off the gantry will lower. There are some workarounds I need to try a bit more, but really a good ending g-code will make it work for now.

Accuracy was spot on in a few trials I have run. Of course, I will be doing many many more before releasing the files.

The lowRider CNC’s first public cruise…