An avid RC’er, Mark Moebes (“moebeast”) made waves with his wildly-successful FliteFest-East 2017 MPCNC foam-cutting exploits… Ryan even featured his FT article here on this site (https://www.v1engineering.com/moebeast-flight-test/).

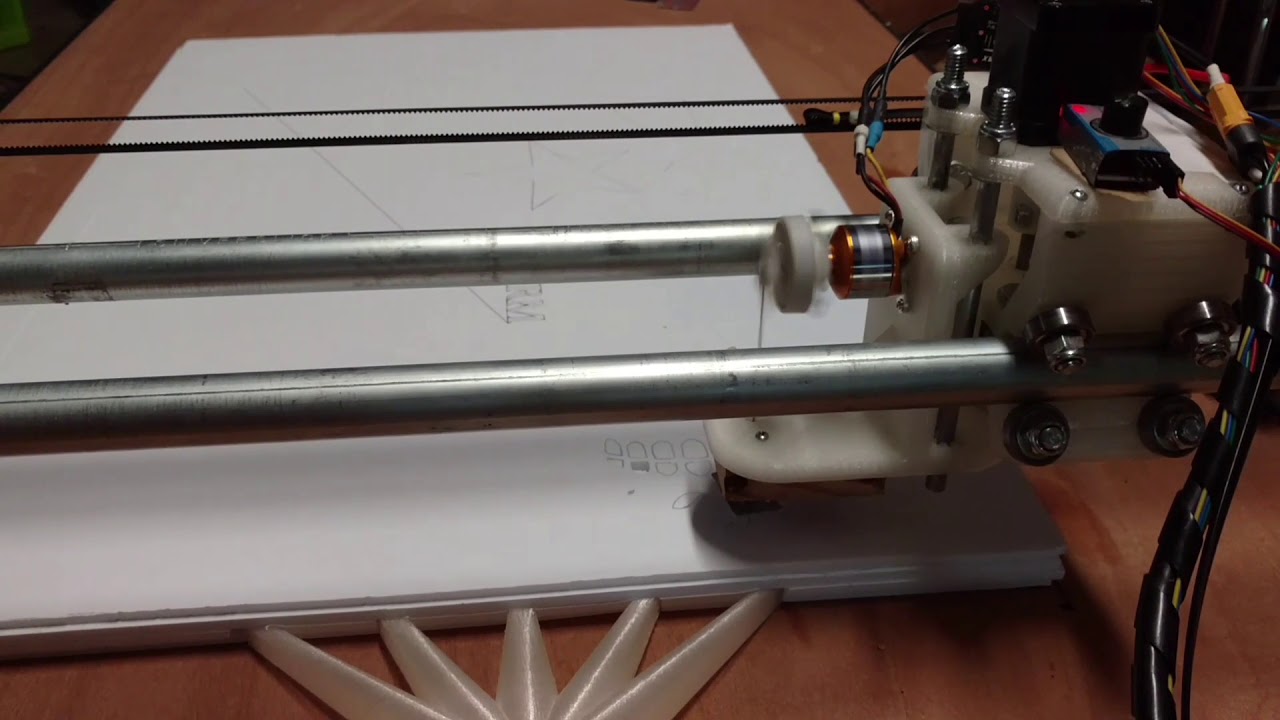

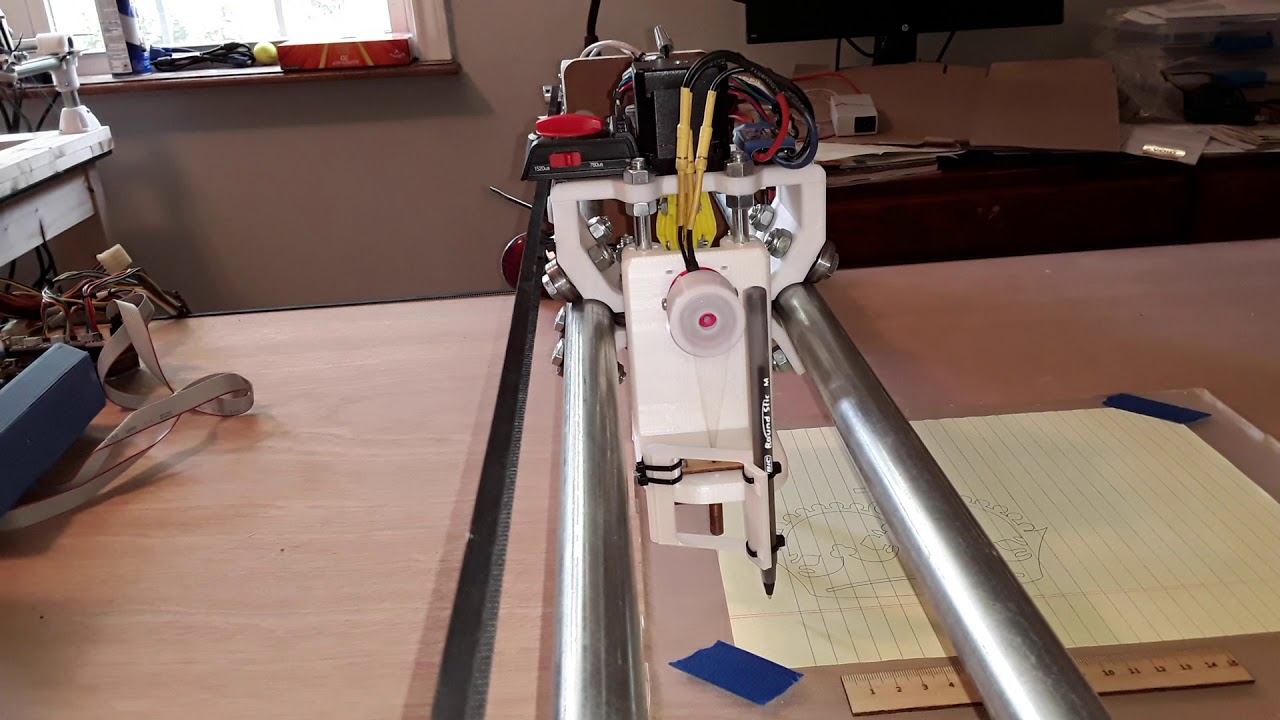

Well, soon after returning from FFE/2017, he set about to… in his words, “see how inexpensive a machine I could build.” The resulting, loosely LowRider-inspired, foam-cutting machine – which he calls “Foam Ripper” – is not a competitor/replacement for LowRider. It is a light-duty machine, using standard 3/4" EMT, having fixed-height (but adjustable) Y-axis rails, and sporting a Y-carriage with limited-range Z-lift and integrated needle cutter… and ultimately it uses one less stepper motor, about half the number of bearings, and a quarter of the hardware, of the MPCNC.

https://www.thingiverse.com/thing:2520214

He also wrote a second FT article describing its construction…

https://www.flitetest.com/articles/another-cnc-foam-board-cutter

And here it is in action…

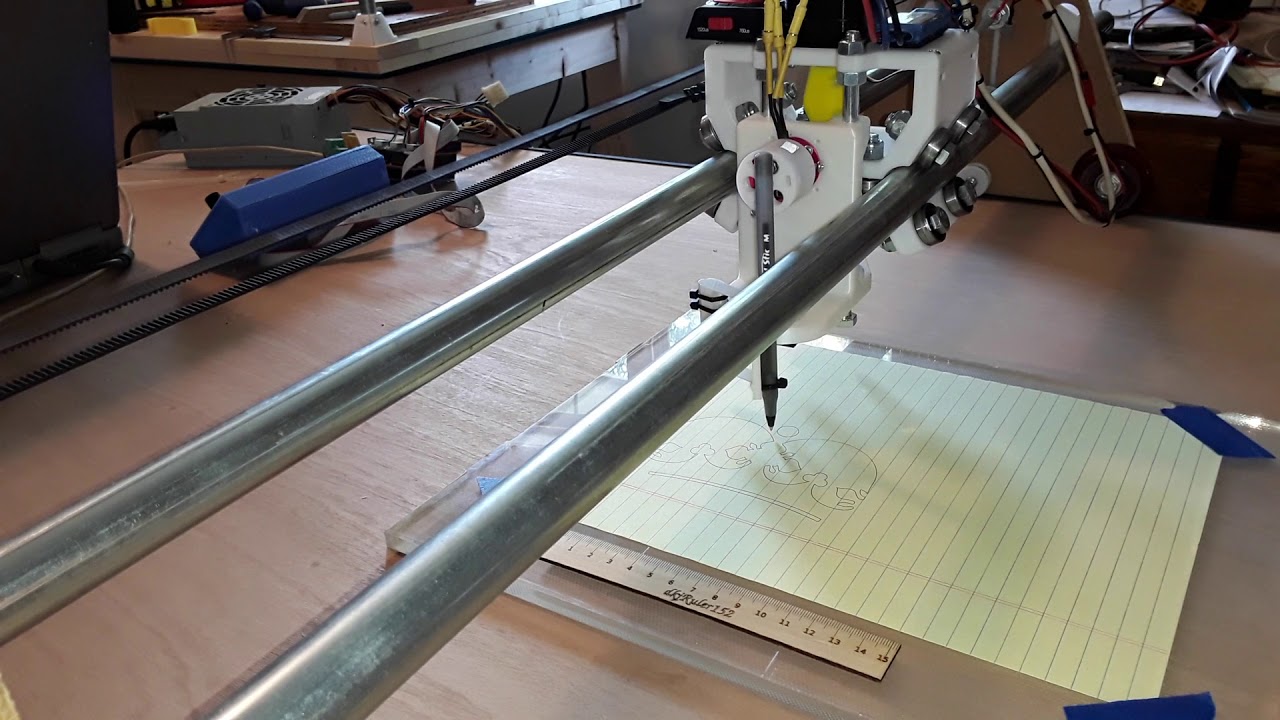

My planets have now aligned… and with my new “Texas rebuild” milling capability and a new needle-cutter slip-on flywheel assembly in development, I have decided to build Mark’s machine. It’s a dedicated machine for light-loads – needle-cutter, pen/marker plotter, drag-knife, laser, etc. – and is best suited to a generally “smaller-than-LowRider” work area. I’ve begun documenting my build in my lengthy needle-cutting thread over on the FT forum…

My build has progressed to the point that I can begin testing and fine-tuning… first, the obligatory crown plot

and a short run-up of the needle cutter, featuring the new slip-on (over the motor bell) flywheel assembly…

Not needing the size or rigidity of the LowRider machines, my build currently uses an 32" x 80" interior door for the work surface, perched atop a folding table.

[attachment file=68029]

[attachment file=68030]

[attachment file=68031]

[attachment file=68032]

[attachment file=68033]

[attachment file=68034]

[attachment file=68035]

One of my first tasks, is to needle cut three DTFB sheets to form the vacuum hold-down system featured in Mark’s article… Jason Hitesman (“jhitesma”) also did a video detailing its construction

As CNC machines go, this may be one of the easiest machines to find room for… it can be made “knock-down” for portability and/or storage. The bed needs to only be large enough to allow for cutting to the extremes of a sheet of DTFB, or whatever sheet material you want to cut. The rolling gantry is easily rolled off the bed, is not-too-heavy (20 lbs?), and will stand up in a corner. The belts are simply clamped along the edge of the bed for use. The bed is stored away like any other panel. Saw horses or a folding table hold it all up in use. No computer required to operate, the LCD controller and electronics can be attached to the end plate… so it stores with the gantry.

This has been a fun build. Eventually, I plan to down-size the work-surface and move this machine into the bedroom I’ve set aside for hobby storage and additional work-area. Cutting foam with the needle cutter is not terribly loud and generates little debris so hopefully it will be happy there, not occupying “center stage” in my living area… ![]()

– David