Or untainted by the silliness.

Playing a bit with my fun new toy…

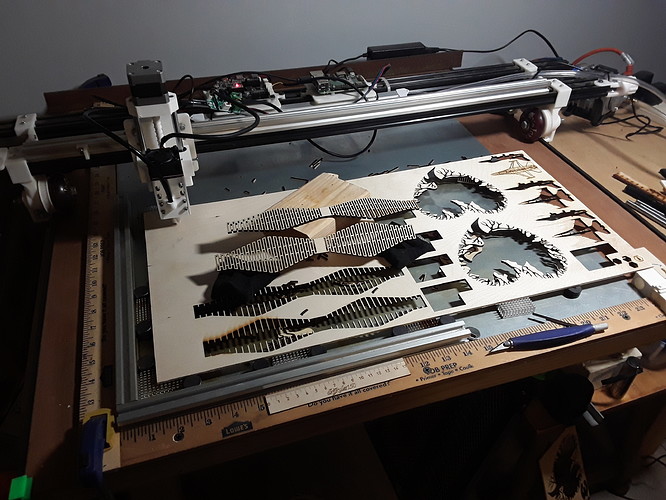

Cut a second “heart-tree” (150mm/min at 100% power, ~35 minutes, one pass, air-assist) because the first revealed a bad spot on the 3mm plywood sheet…

Lifted the sheet off the machine and the figure dropped free of the sheet…

Remaining bits fell out easily by themselves… leaving a nice delicate figure intact

The first tree has a few bits that didn’t cut through because of the bad spot in the plywood sheet and can’t be removed without breaking fragile limbs…

Still impressed!

– David

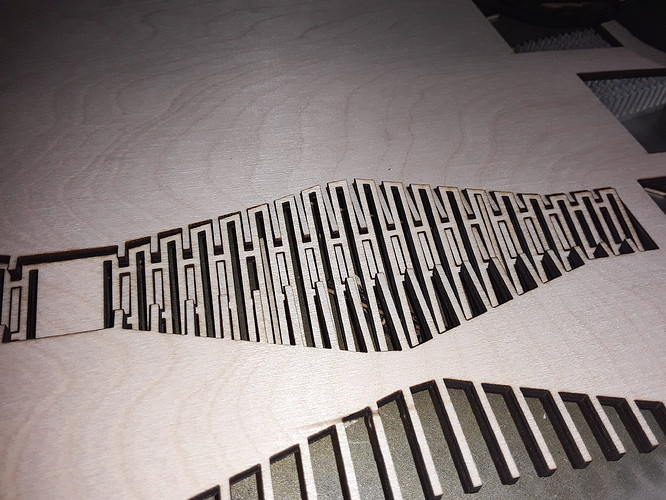

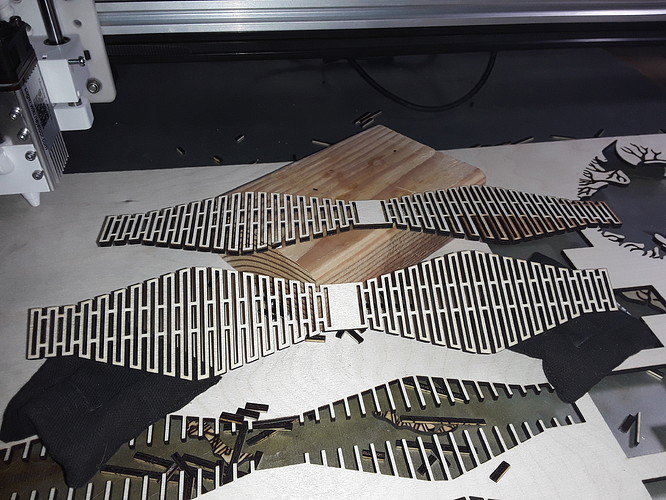

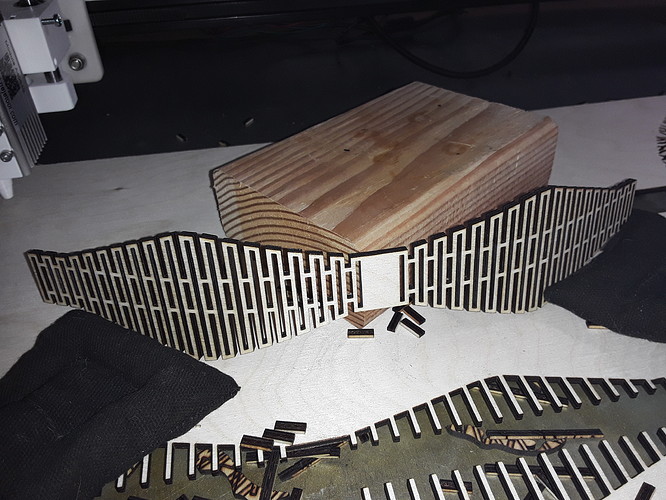

Getting ready for the prom… who knows? Might find that special lady friend to frolic with… and need a bowtie

Oops, first cut okay but air-assist line kinked toward one end… turned sheet to try again…

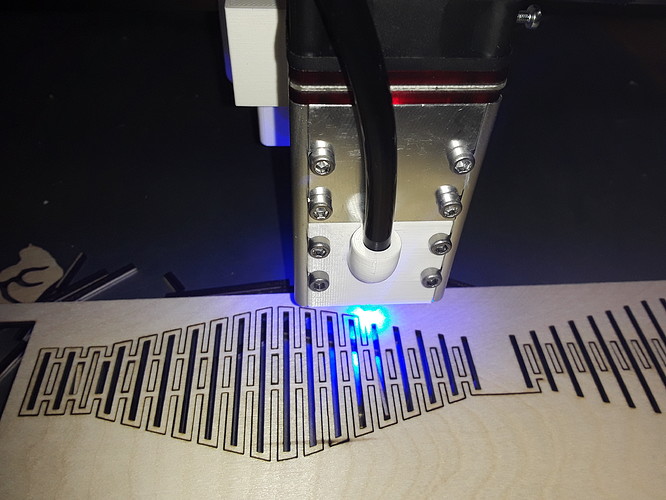

Neje A40640 dual-diode laser module (~15W), 3mm birch ply, about 40 minutes per bowtie at 200 mm/min feed, 100% power…

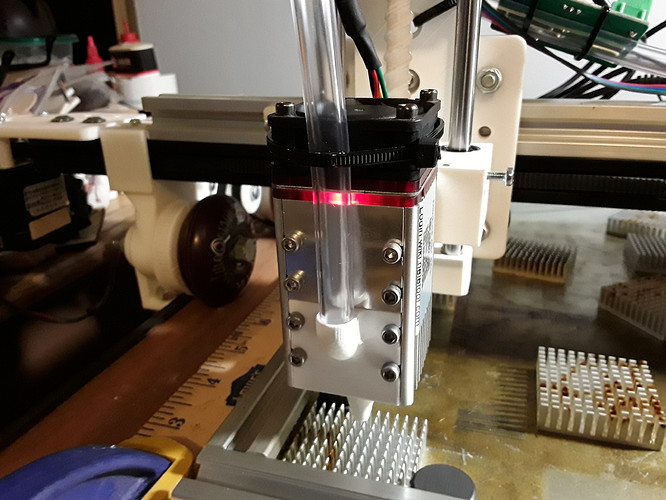

Current state of FoamRipper machine with new Z-axis and laser module…

– David

Looks great! Is that just readily available birch plywood? I notice a few company’s laser cut what looks like birch but seems to have a very thick single core

Thanks! I ordered this 3mm/1/8" x 12" x 24" plywood off Amazon last year IIRC. I’ve found a couple of difficult to laser-cut spots on the couple of sheets I’ve worked with so far but they were fairly small and the rest of the sheet cut nicely.

More adventures in air-assist… and variations on a theme…

While reworking a different laser machine, I revisited a previous air-assist configuration from the past – an air-mattress pump and router speed control for regulating air flow…

but I noticed that with my last air-assist setup using 4mm/6mm (ID/OD) tubing and ball-valve, the air flow from the mattress air-pump seemed too greatly restricted. So I reworked the printed air-assist nozzle to accept larger 3/8"OD and 1/4"ID vinyl tubing from big-box store…

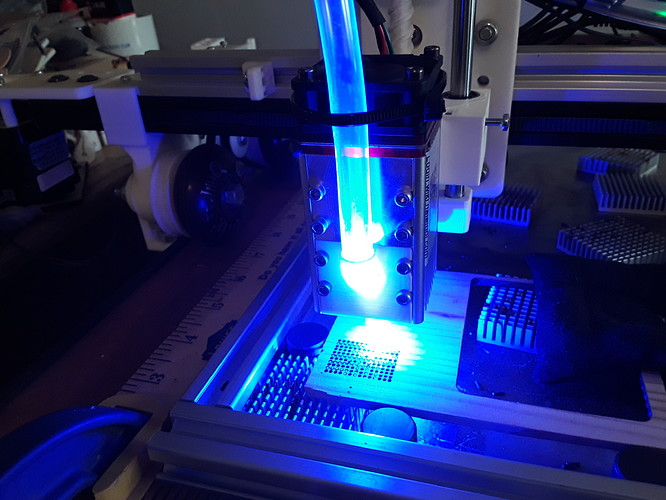

Clear vinyl tubing installed on Neje A40640 laser module…

resulted in unexpected light show

3mm birch ply cut at 150mm/min and 100% power, in a single pass, falls through…

blackened, though not charred, edges and holes…

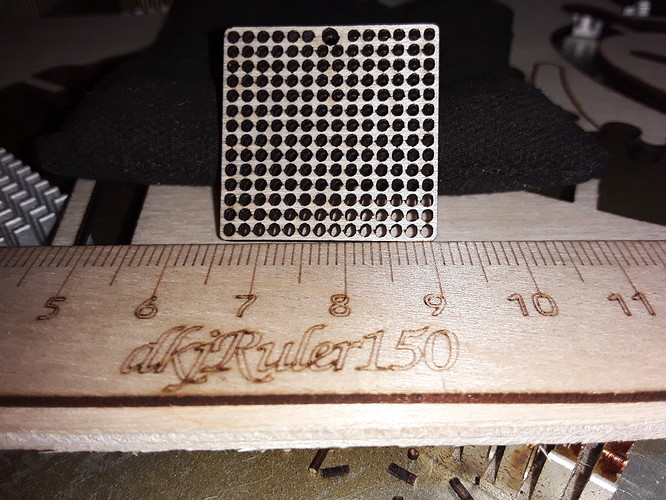

a cross-stitch pendant blank, waiting for my daughter’s inspection and approval…

AFAICT the air-pump and larger tubing are equal to or better than the aquarium compressor and smaller tubing as far as air-assist goes. Whether or not the air-pump holds up to the unconventional use with router speed control and restricted air-flow remains to be seen.

It’s fun to play with though…

– David

Nice. I need that larger tubing part. I’m having to use a metal tube to go from the larger tubing size coming from my compressor to the smaller one on the current part.

David,

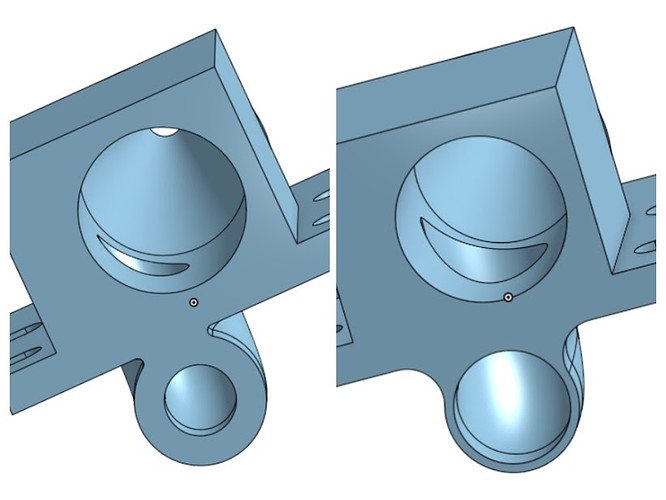

I think I’ve added it to my air-assist “thing” earlier today but for some reason that “thing” has never given me the option to make it “public”…

If you can’t find it out there, here it is…

Neje40WNozzle-r3.zip (469.2 KB)

– David

Dang it. That one’s too big.

Neither one seems to fit the aquarium air line tubing I have.

It’s ok. I have the first version working with the adapter I made.

Thanks for the part designs.

David,

That new nozzle design accepts 3/8" (9.5mm) OD x 1/4" (6.35mm) ID vinyl tubing I got at Lowes just a couple of days ago. In fact I bought several sizes down to 1/4"OD as well… just in case. I don’t remember where you are but being inexpensive and readily available here, I can’t imagine any big-box store near you not having something suitable in stock.

What tubing do you have? If you can provide the OD, I should be able to adjust my CAD model and give you an STL pretty quickly.

– David

Oh. I know I can go get some. I just already have a bunch of air line tubing from petco.

I’ll have to grab the OD tomorrow.

Ok. Ran outside this morning. Funny enough, the tubing still has the tag on it. Looks like I’m using 1/4" OD tubing.

Funny enough, I have a 20’ coil of the same stuff… one of the smaller coils I picked up on my last Lowes run. However, somebody doesn’t know their conversion, imperial to metric, on your label… 1/4" isn’t 8mm, but 6.35mm. So I measured mine and it is indeed closer to 6.35mm… I’ll use 6.5mm for the nozzle. I’ll also include one for 8mm just in case…

Here they are…

Neje40WNozzles.zip (964.1 KB)

It’s an easy thing to adjust for a different size tubing… just let me know

– David

awesome. thanks. I’ll give it a go later today.

Thanks. I got a chance to print the parts and give them a shot. I went ahead and printed both.

The smaller hole size worked better. My printer tends to squish the first layer a bit, so it was snug. But it worked really well. Thanks again for the adjustment and new part.

I just ordered this one:

https://a.aliexpress.com/_mK3bUVs and 9mm tubes. Do you reckon that a regulator is necessary? What is the purpose of it?

Thanks a lot for your nice nozzle! Now I feel ready to try out my own laser

In general, a regulator is used to control how much of a higher pressure source is allowed through to a particular use. I don’t think that inflator pump will generate enough pressure that a regulator will be needed.

If that inflator is anything like the one we’ve got for blowing up air mattresses or “floaties” for use in the pool or lake, I don’t think you’ll enjoy the level of noise it makes. It’s one thing to compare the shop vac to the router spindle, another completely to compare that screamer to a virtually silent laser.

I got a long hose, so that I can keep it I’m another room. It’ll be less noisy than my compressor, I’m sure!

Oh, goodness… I really don’t know. You’re the first to pursue it to my knowledge. I know cheap mattress pumps are plastic and loud and may not last long, mistreating it as we’re doing here… the one I have is all/mostly metal, seems far better quality, and runs more smoothly than the cheap ones I’ve had. I think I “inherited” this one from one of my kids somewhere along the way…

Please don’t hammer me over the “technicalities” but I’m not sure you’d call the router speed control a [pressure] “regulator”. It’s just adjusting the volume of air-flow and letting the nozzle create some level of pressure… kinda like putting your thumb over the end of the water hose to create a high-speed stream of water. The pressure against my finger indeed varies with the speed of the mattress pump…

One disadvantage of the speed control, compared to the ball-valve is that it doesn’t go below some rpm value… and even the lowest setting is way too much “air-assist” when engraving… where you want virtually none beyond just enough to prevent soot/smoke from entering the nozzle and coating/damaging the lens. The dark smudged area was with it at lowest setting, everything else it was completely off. The ball-valve can be adjusted to almost complete cutoff… and just the barest amount to keep smoke and soot out of the nozzle.

I suspect my earlier version of air-assist works as well or better… the aquarium compressor, 4mm ID air line, ball-valve, and printed nozzle. I’ve not found an inexpensive ball-valve for the larger tubing… if I could, I’d replace the router speed control with it in a heartbeat for finer control.

– David

Ah, I appreciate your thorough reply! I guess I’ll just have to wait and see how it works out. My ideal setup would be to run some pipes to get compressor air to the cnc room and have an air regulator. If I close the door, the compressor won’t bother me much…