Hello!

I started 3D printing early on in 2015 with RepRap, bailed out for a while after getting poisoned by it in early 2017. I’m now sensitized to the monomers/polymers, adhesives, and all the 3D printing related chemicals. Heads up to all makers, vent or don’t print! I bought a cheap 3D printer last summer and upgraded it, solely to print the LR2 components. I only print outside now during warm months and stay away from it. I didn’t want to give up on design/making, so here I am building an LR2. Sticking to non-sensitizing hardwoods, unless I take the machine outside.

I’ve been collecting components and materials to upcycle, buying at the hardware trying to support them during COVID, and keep costs down.

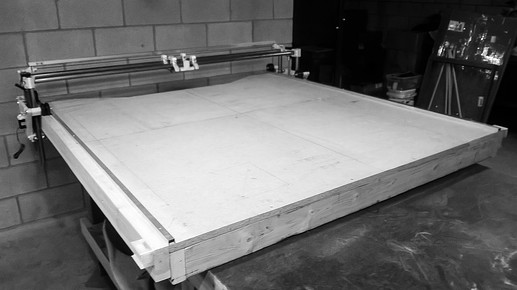

Full sheet table is 65"x61" and can easily be split in half if I want to take the machine out of the basement for big home and offsite projects; so it’s ‘mostly portable’! I padded the 48x48" workspace to c. 50"x50". Machine rest area at the back for easier access to the X-carriage; should have been a couple inches deeper, too late now. I also got one side of the table slightly out of square and ended up cutting it down with the radial saw and a bandsaw; not fun. The 2x4 rails are planed on the edge where the wheels ride; I’d plane every side if I were to do it again.

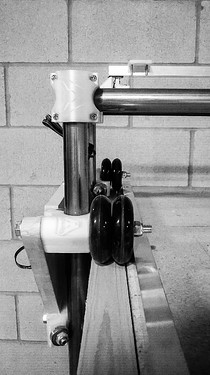

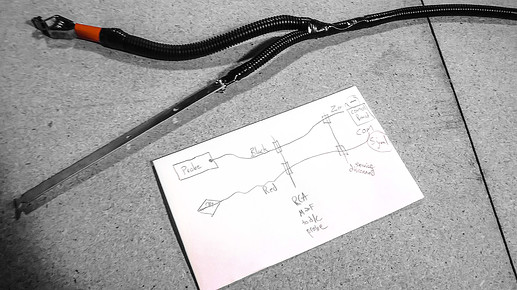

Natural PLA throughout, got some cracking on the lower bolt passages in those big X-ends, probably due to thermal variation during printing; otherwise all good. Ordered most of my components from ZLYTECH and 1" (24.5mm) steel tubes off Amazon. My roller wheels are strangely narrow. Bought spacers from Ryans store, but they’re like 2x too wide, so I put the other four wheels on and now it’s a dually! Otherwise everything used for the table, wasteboard, Y and X-plates (5/8 old 90s bookshelf), wiring (CAT3, bell wire), Megatronics board, and other bits are all upcycled.

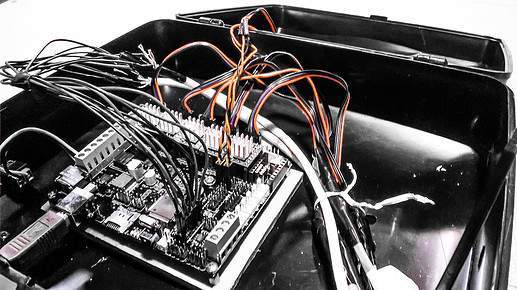

Really liked @kzdesign’s machine and @vicious1’s table renderings, so took some early inspiration from them in design, operation, setup. Used @kzdesign’s belt tensioning system, had to put spacers between the rail and belt mounts; the belts ended up not being parallel and were rubbing on the pipes. Cracked the x-belt tensioner clip, used it as a template to make an aluminum one; all good now. Upcycled my mum’s weird plastic mixer box into an electronics enclosure.

I got stuck due to a Marlin issue with the Megatronics board and setting up dual endstops; thread and solution can be found here.

Specs:

- (52.75" x 50") 1340mm x 1270mm final workspace size

- Megatronics 3.0 Controller, 96oz NEMA17s, T8 lead screws, 32 stepping

- Dual endstops, fully adustable on all axes

- Aluminum channel wheel guides / debris barrier

- @kzdesign’s belt tensioning system

- Upward homing orientation for easy material loading and probing

- Configuration and Configuration_adv files

- Router, coming soon.

Quick Overview of Build:

(Those switches were swapped out for bare switches (like those available in Ryan’s shop, as the makerbot ones can only be wired NO apparently; made little plates to remount them as pictured)

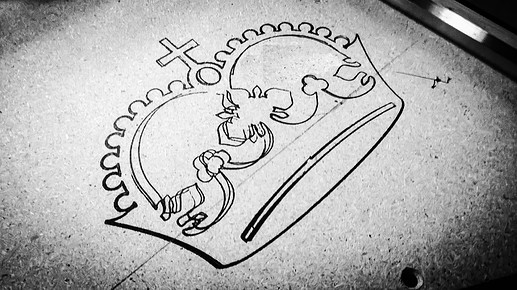

First output, sharpie marker, stuck through a 1" thick cardboard block, thus some doubling effect, still super cool!

Some refinements after learning how to use G92 to not accidentally draw on the table.

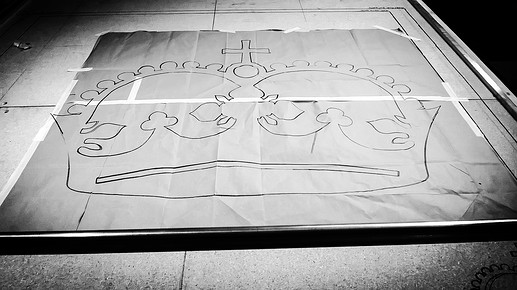

BIG crown test!

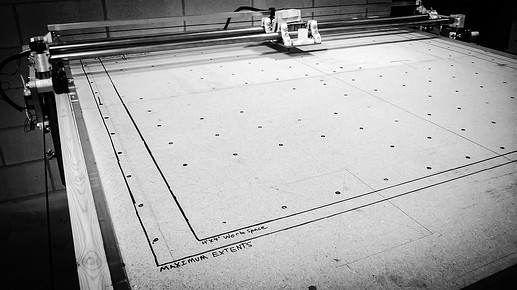

Hole grid for clamps… draw first, to avoid stupid things happening later.

I found that 1340mm on X ran into issues (crashed), so I reduced it to 1330 for safety. Drew 100mm and 200mm lines on a paper shopping bag to make sure my belts and steps values were correct (they are). I didn’t set the bounds of the machine into pronterface, which seemed to totally ignore my software endstops while drawing the maximum extents on the table. So, heads up… make sure you set those values in your control software to help further avoid crashes.

The only thing that’s odd is that I get a ‘tik-tok’ like clock sound coming from the Y-plate on one side of the machine. Occurs on rapid moves, while returning to home from an extent of Y. It emanates from the y-plate area. I’m not 100% sure where it is coming from, but I’m guessing it’s the front wheel due to the lack of spacers? Vaguely reminds me of a wheel bearing sound on a car. I loosened the nut, to reduce pressure on the bearing faces as it appears to be tighter than the others… Any other ideas?

I have not picked a router yet. Considering a Dewalt 611, Makita RT0701C, or possibly Rigid. I’ll be drawing around on it for a bit, until my brain adjusts from 3D printing. It’s even cool as just a huge plotting machine!