Yeah but if I remember correctly I think his emi issues were rooted in the particular plasma machine he was using. People have reported good results with this specific model so hopefully I won’t have as much trouble as @forcerouge did. Knocks on wood

I will watch I don’t really need one not sure what I will use it for but is sure is cool if it does work like thay say maybe I’ll find a good use😀

(Cross posted here: https://forum.linuxcnc.org/plasma-laser/36734-lets-talk-wiring-and-emi?start=20#177702)

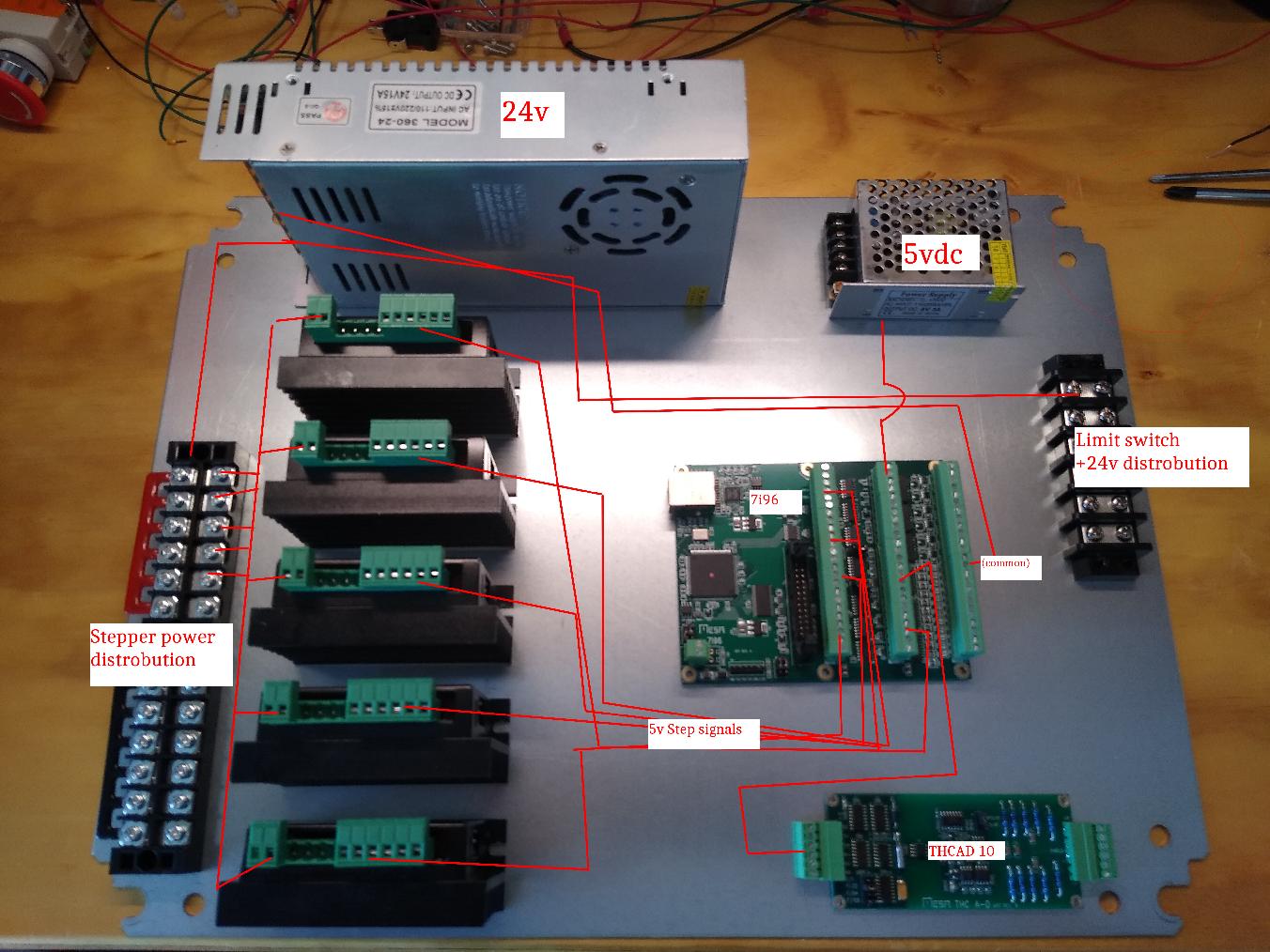

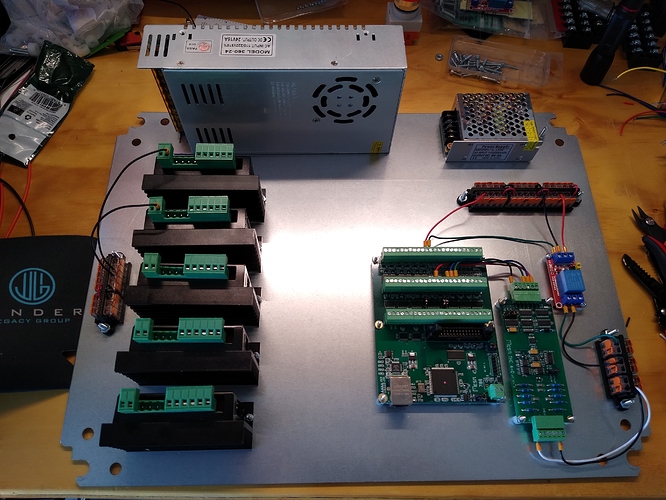

I’m trying to be very careful about EMI but I aint no electrical engineer. Anyone have any opinions on this control box layout? This will be mounted vertically with the stepper drivers up top and the motor and signal wires coming up through the bottom of the box (right hand side of the photo)

If the control box is metal, and grounded, there won’t be any emi going in or out. It will act like a faraday cage. The fact that it looks anodized or painted makes me think it might have trouble being grounded, so you might want to grind off the area around one of the screw holes so the case and the door can both be at ground, and then ground the whole thing with a screw or to the power supply case (which should be ground, unless the manuf. are jerks).

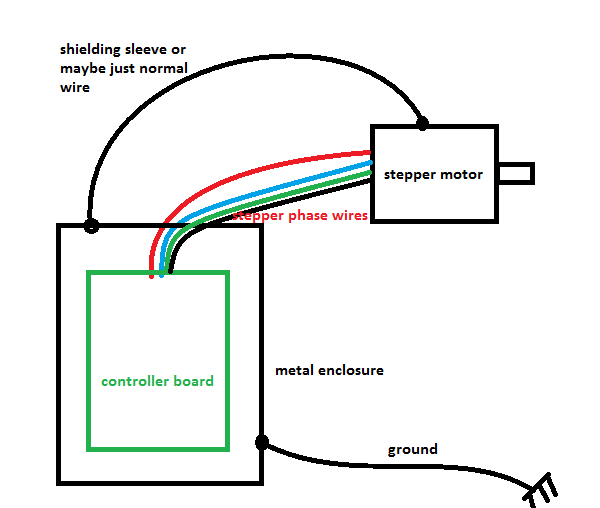

IIRC, Dui’s biggest takaway from his mammoth grounding project was to put the motor cables in a shielded cable and then ground that shield on one end (the controller end, presumably).

There shouldn’t be any significant EMI inside this case.

What 5VDC power supply is that? Is that from the 24V, or from A/C? I’m just curious because I’m not happy with the DC to DC converter I have in my printer for the raspberry pi.

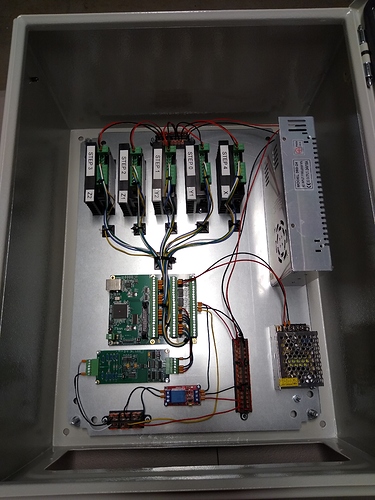

It’s a bonafide steel NEMA enclosure! The mounting plate in the photo is galvanized steel. Both power supplies are 120vac input.

I do plan on grounding the mounting plate to the enclosure’s grounding post. Actually, the first thing I did when I got this thing in the mail was poke around with a multimeter for continuity and discovered that the mounting plate is isolated from the enclosure. I haven’t figured out of that was intentional or simply due to the rubber washers used to mount it to the panel that are for water proofing.

It can be dangerous, especially if you’re running A/C close to it, because that can arc. But you can short stuff that way anyway, so you might as well ground it.

To both ends actually. What I found out worked was to ground the motors casings, once they were grounded it worked like a charm. I’m not sure I even needed to shield the motor wires, but I used the shielding to achieve both, connectin the motor casing to one side and the earth ground of the electronics bo to the other.

@OP If this explanation is not clear just let me know and I’ll make you a quick drawing.

You grounded both ends of your shielded cables? I had read that creates ground loops. Maybe a drawing would be helpful.

The motors aren’t otherwise grounded, so it won’t make a ground loop.

Oh ok I see what you mean, you’ve connected both ends but only draining one end.

How do you physically attach the ground wire to the motor’s case? (edit) I’m guessing just attach to one of the case’s screws?

I just used some aluminum tape, but I guess securing with a screw should be better.

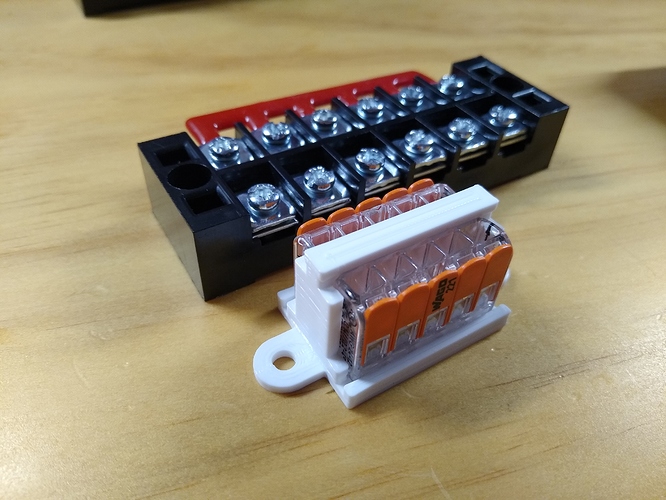

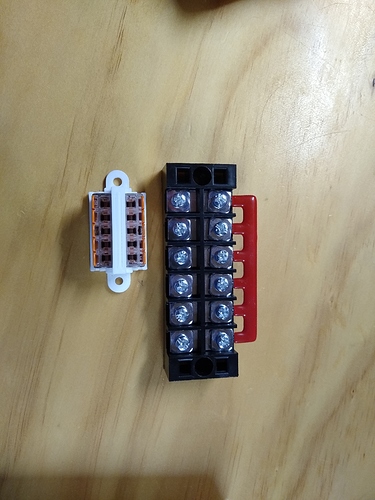

I really like using these wago 221 lever nuts, I’ve got a couple boxes of them handy for just in case. In my entirely unqualified opinion they seem to make for great connections and I like how compact they are.

It occurred to me that I hadn’t even considered using them in my build. Then it occurred to me that I could 3d print mounts for them and make power distribution blocks within my control panel and save a bunch of space. If it occurred to me then naturally I wasn’t the first to think of it… I found several models already on thingiverse. Here’s an example I just printed https://www.thingiverse.com/thing:2075219

Just thought I’d share.

So after using up space for jumper wires the wago block would have 7 distribution points while the screw terminal block would only have 5… I guess you can always double up wires on screw terminals though I’m not entirely sure if that’s a good practice.

Well right now is a hell of a time to run out of hookup wire. I thought I would get to burn some steel today… I guess it’ll be next week. Anyway, here’s the final layout. I’ve decided to use a relay to fire the torch, though talking with the Mesa engineer he didn’t seem to think it was necessary since the 7i96 outputs are each optoisolated anyway.

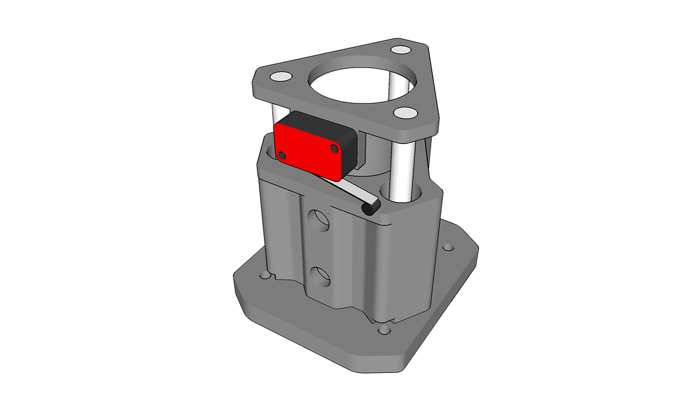

I couldn’t leave well enough alone… Prototype floating torch holder based off @uthayne 's design

Also Amazon delivery showed up with my hook up wire. Should be burning metal shortly

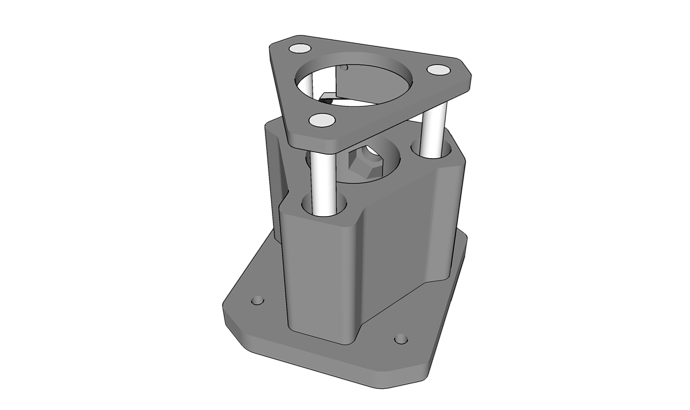

Latest floating torch mount iteration. Suggestions are welcomed before I print this thing

This was done in sketchup… Anyone have favorite tutorials for learning fusion? Also, what kind of computer hardware do you need to run fusion comfortably? It’s crazy slow on my laptop.

FWIW, onshape works in a browser and is very powerful and free for hobbyists.

I’ve been resisting onshape, fusion, newer sketchup for years now because of the cloud model. I’m still using sketchup 2016, it’s gone downhill since google sold it… But I guess I need to get over it and get with the times. I’ll give onshape a look too.

I get that. But I own a bunch of software from the 90s, 2000s, and 2010s, and I can’t use any of it. It does me no good to only run locally if it is completely obsolete in a few years. I am becoming more of a fan of cloud apps mostly because I can try them and they don’t leave a bunch of poop all over my machine. If we only bring my wife’s computer on a trip, I can sign into onshape, or my email client, or google sheets, etc. The companies keep it always up to date and any support includes all the information they need to fix it, so it is generally good quality.

It definitely doesn’t work for everything. I don’t like things like the printrbot printer being tied to the cloud. I don’t like google storing my interactions with the software for the next 10+ years. I can’t use it for work, because of good policy.

From a developer’s perspective (like me, on sandify) it is nice to not worry about releases, delivery, installers, and debugging someone’s virus riddled machine conflicting with your software. It generally just works.