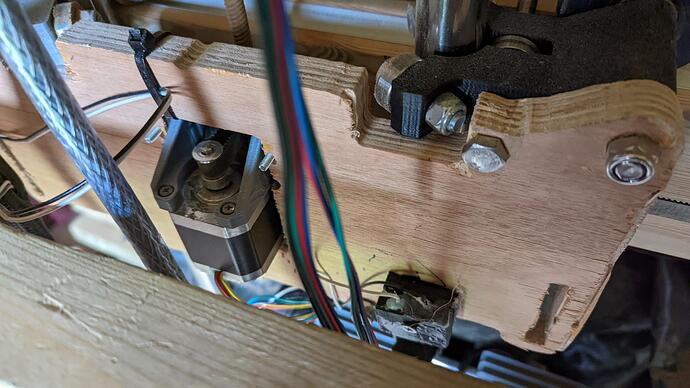

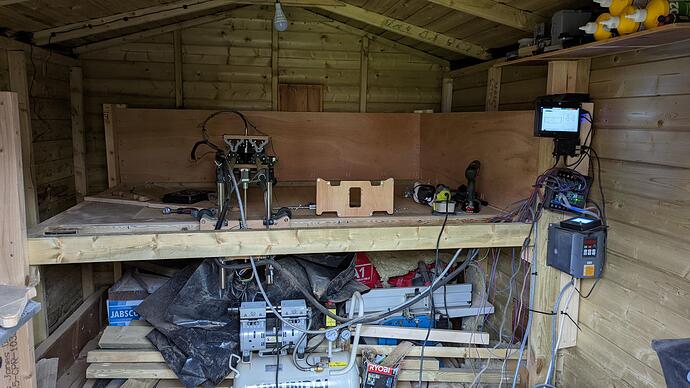

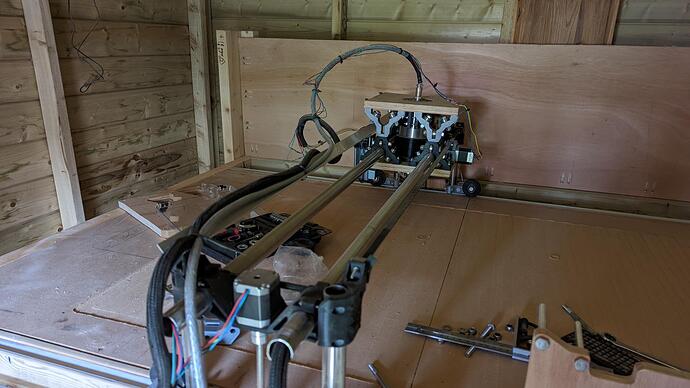

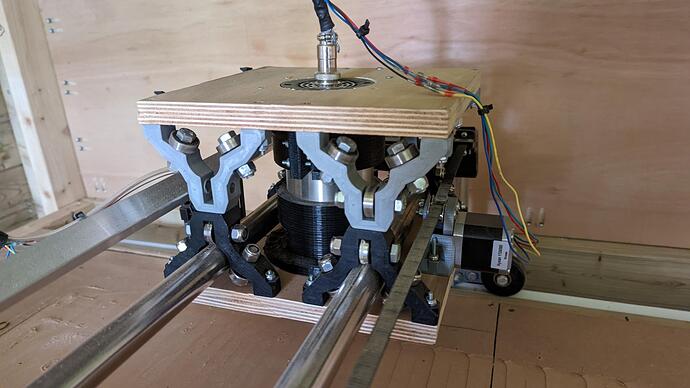

Started last year and gave up because my bits where always burning, this year I reached out on the forum and was told to check the rotation of my spindle and it was the spindle spinning the wrong way why it was’nt working. 1.5kw chinese spindle and a Sculpfun S9 laser. Putting cnc in a sound proof box as it’s in my garden shed so don’t want to annoy the neighbours. Printed Y plates on my 3d printer and then printed at about 3mm depth in ply and cut them out by hand, changed plates over and finally printed plates using 18mm ply. Still a lot of tuning and tidying but she’s getting there.

Double glazed door with 5mm perspex that I found in my shed. Just need to put a box in underneath to soundproof the bottom.

Bottom box now installed. First test with router spinning at 15k

Router off; 39db

Door open : 54db

Door closed : 44db

Now onto the towels, if they don’t work the dog goes in

Hi all,

Finally finished the enclosure with 3 layers of towels on the sides and top and 2 layers on the bottom underneath the table with a false floor.

All off 40db

Vfd on 44db

Router spinning at 15k 45db

Cutting mdf 50db

Cutting mdf with door open 60db

Far better than it was open, could make better but it’s fine as it is.

All the white sealant in the pictures is AC95 if anyone is interested, supposed to help accoustics, used 6 tubes of 900ml

The gap underneath is 8 inches so had to make a channel so the cables weren’t getting tangled up. Enclosure is approximately 7ft by 5ft

Hope this helps someone as much as others have helped me

Thanks for sharing enclosure details. Can see Rock Wool in the pics, something I used throughout our home. Does your enclosure use Rock Wool? Cheers!

Hi Aaron,

I was thinking about using it but after reading up about it decided not to. Did use it underneath my false shed floor though. I used towels after watching YouTube videos