Well, I had a Low Rider before and I loved it. The design is awesome and who knew that a machine running on wheels could be so accurate.

My LR2 in SoCal - LowRider CNC / Your Builds - V1 Engineering Forum

I even did some inlay with this and some signs

My first attempt(s) - Things You’ve Made - V1 Engineering Forum

But then… I needed my garage back. I am working in a one car garage and got neighbors on top of it and to the left. So I was always scared of running the router for too long because of the noise. And then I could not store the LR2 properly - all the walls are used already so I could not place the table anywhere.

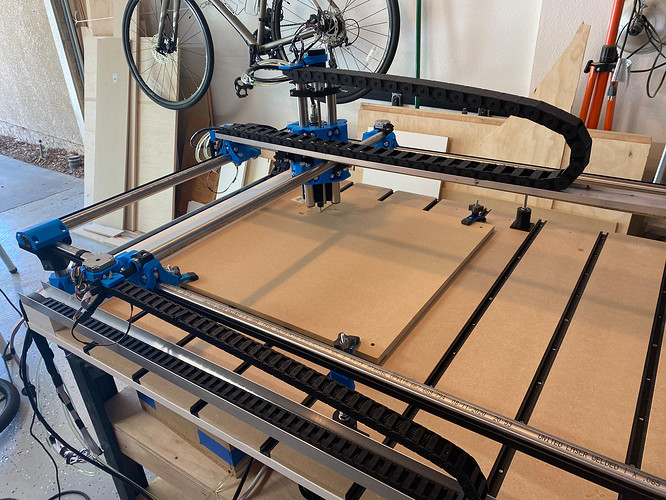

I started planning for a MPCNC shortly before the Primo was announced and then held off to wait for it. I have a huge work table at the end of my garage that I fitted in exactly so that the hood of my car would fit under it when I need to use it. My dream was to one day make a 3D carved US flag so - I went bigger then recommended and tried to address all my constraints:

- my car still needs to fit into the garage

- it must be more silent

- it should be big enough for my future dream project

I started printing when the Primo was released, but had to pause the build for months because of tragedy in this last pandemic year …

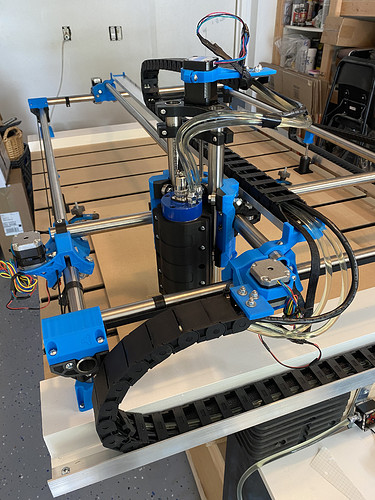

However long it took… here is the result:

The tubes are polished stainless steel. The “bed” is lowered in a way - I assumed I can always put a few MDF plates underneath to get the spindle up higher if needed to avoid jitter, but at the same time I keep my option open for carving or cutting something deeper. I beefed up the Z-axis stepper and I added supports along the Y-axis. To address the noise of the router I went with a water cooled 65mm spindle. I am impressed how silent it is until it hits the wood, but even then my shop vac seems to be louder. And then … I can still roll this entire contraption to the back of my garage and drive my car in when needed. As said, I tried to make the most out of my limited space.

It is not 100% finished yet. I bought a really light laser as well and will replace the lid of the spindle with a spindle/universal mount hybrid.

Amazon.com: Sovol 3D 500mW Laser Module, 12-24V Engraving Laser Head Kits Magnetic Design with Goggles, Test Wooden Boards for SV01/ SV02/ Ender 3 V2/ Ender 3/ Ender 3 Pro/Ender 5 / Ender 5 Pro 3D Printer: Electronics

This one should plug in directly into the Rambo board. I have not tried that yet and I am still in the process of modifying the spindle cover.

And then I am unhappy with the water cooling of the spindle. I got two different peltier cooling elements and they do seem to do nothing. The cooling fluid temperature rises about 1 degree in an hour of cutting, but still it should go down or at least stay constant.

After I address these last two things I can finally close the lid of the rambo enclosure and CNC a bit of a “control center”.

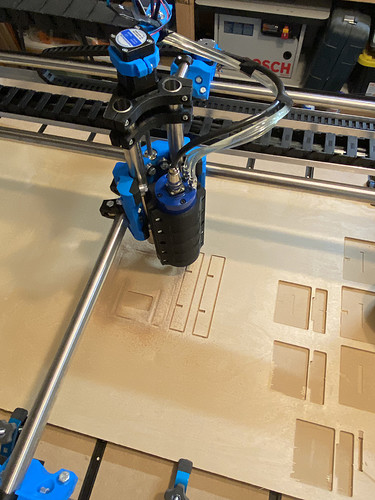

My first test project is in the pictures. A scanner phone holder: