I may have done that once or twice…

Just finished constructing colibri. It is pretty neat! When the color is done I’ll post some pics.

It’s the number for pizza delivery?

Oh man! I am so envious of you right now! Photos please!

What is a colibri? I searched and only came up with hummingbirds. I’m reasonably sure you aren’t Frankensteining some hummingbirds, but who knows.

That vac bucket mount resembles a toilet seat… hhhmm brain fog sets in… you might just find yourself sitting on it with ya pant down mate. Might wanna put a warning sign… just in case

It runs straight with no side to side motion now. I could have likely solved this with some 1/8" aluminum angle and v-groove bearings as well. The only piece I have movement in now is the Z to X printed piece where the stepper sits for the Z axis on either side. I am planning to try milling the aluminum corners that @Rich made this weekend.

It’s high enough on the wall and my “trick shot” game is bad enough that I don’t think it’s a danger. Especially in a garage that has the same temperature as the ambient air outside in Minnesota.

Well… wasn’t expecting that .

Posted a pic. Tolerances required for the colloidal cam is pretty important, everything else was a easy enough for the lowrider.

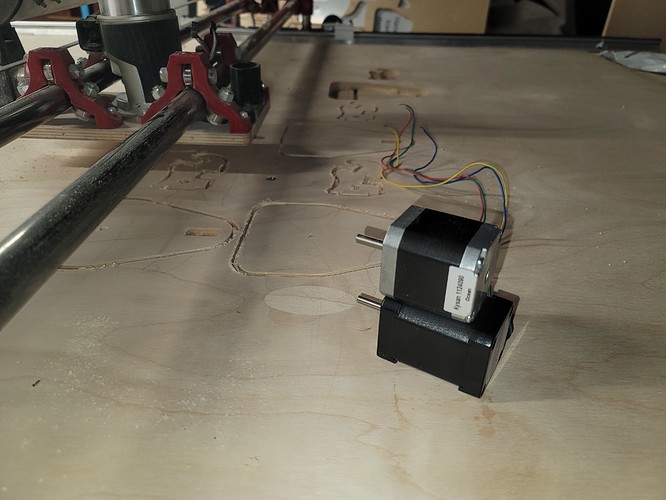

I had a stepper induced fire the other day. One of my Z steppers failed on me, plunging the router bit into the wood until the collet was friction burning its way through. I confirmed the wiring, stepper driver, etc were all good and then ordered up some Stepper Online 92ozin NEMA 17 steppers.

Installing these went smoothly and my issues were resolved pretty quickly. I did bump the Z stepper amperage up to 1.2 from .9, and that made a very large difference in the Z holding torque.

My wife put the kibosh on my NEMA23 upgrade, so that is on hold for now. Instead, I picked up five of these units and will be upgrading the Y plates with some tweaked designs for a 1" Y plate with enough room to hold the steppers.

Scary I had a power blip cause that to happen I was glad I was right there. It was caused by my table saw starting causing it t o plunge and start a fire

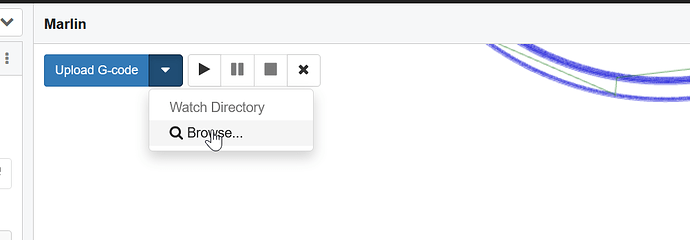

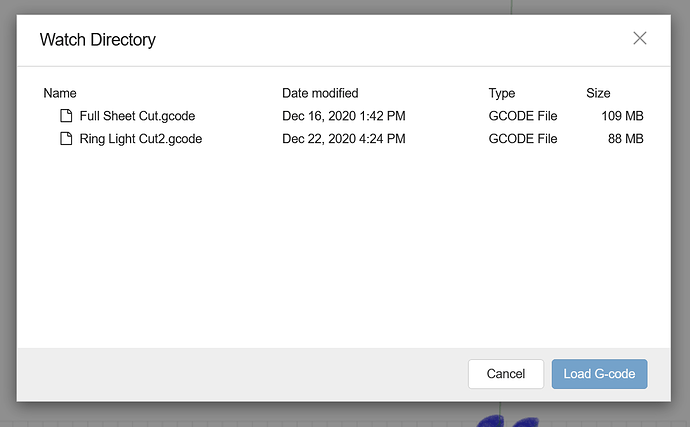

I’m using v1pi to control my LR2 and manage the cuts. I’ve been having issues with some fairly large and complex cut files, and have been unable to load them via a web browser, as the CNCjs web interface crashes, disrupting the upload.

The solution for this is to enable a “Watch Directory” and upload the files via SFTP or SCP from my system.

CNCjs supports looking for files in a folder on the system, and you can load them from there through the web interface. You upload the files to this folder using FileZilla or WinSCP or some such and then just select the Watch Directory from within the web interface and load the G-Code.

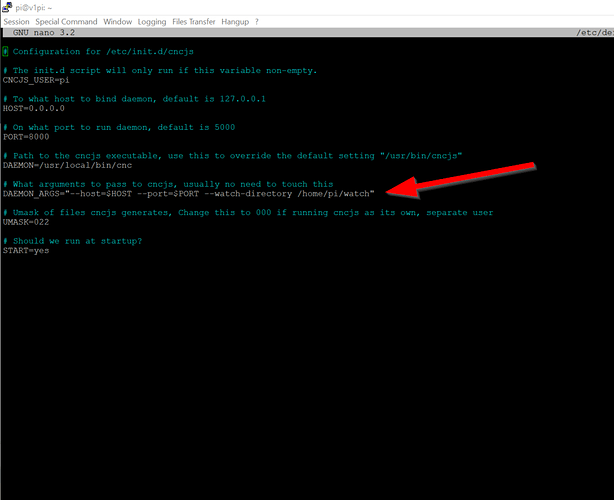

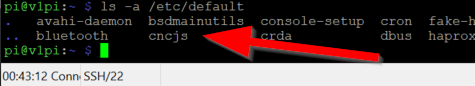

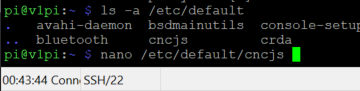

You can enable the Watch Directory in v1pi by editing the cncjs file located at /etc/default/cncjs using your editor of choice. I am a fan of Nano. Type the command sudo nano /etc/default/cncjs and enter the password when prompted.

Arrow down to the DAEMON_ARGS line, and immediately at the end of $PORT in front of the last double quote, type in --watch-directory /home/pi/watch, and ensure that the double quote is at the end of the line.

Hit Ctrl O, Enter, Ctrl X, Enter, and you’ll be back at the command prompt.

Type mkdir /home/pi/watch and hit enter.

Restart the CNCjs service by typing: sudo systemctl restart cncjs and hitting enter. Enter the password when prompted.

Nice writeup.

The Watch directory is really handy. I’ve been using it since shortly after I built my Lowrider, but I wasn’t thoughtful enough to share how to do it. It just didn’t occur to me.

Mines setup a bit differently, as I have a Linux centric house, so I used NFS.

I have a pi setup as a fileserver (primarily used for backups), and just created a shared directory for the gcode files. Both my primary computer, and the V1pi automatically mount this directory on boot. Anything I save to that directory is automatically visible to the V1pi. It’s totally seamless…from a user perspective NFS filesystems are indistinguishable from local ones.

I think a functionally identical system could be done with Windows fileshares or something too…

I know enough Linux to be dangerous, so setting that folder up as a share isn’t something I have knowledge of how to do without consulting with Professor Google… But that is the ideal way to set it up. I’ll have to look into how to make that happen and then add some extra instructions for it.

This is great and I would like to add this to v!pi. I wonder if it makes sense to make it the same directory as octoprint uses?

I’d think different folders would make sense. I believe there’s an “auto start” option in Octoprint, and I don’t think we’d want 3D printers to try starting a cut file, and vice-versa.

I agree that different folders are better. You can name them whatever you would like to make them consistent. Setting up a Samba share with both folders listed underneath it would also be good to allow file copies…

Additionally, I’m still getting web interface crashes even when loading from the watch folder. It’s almost like it’s a memory issue and the interface momentarily drops. A refresh of the page will reload the interface, and a few moments later the file I was loading renders out. I’d like to find the root cause of this and increase the allocated memory or whatever needs to happen.