I’ve been working on making my printers print faster and have tried a few things. First, I had a bunch of low torque(39oz/in), motors so I tried with 2 motors per axis on a Piper1 V2.

That turned out to work pretty well. Then I bought higher torque motors (84oz/in) on my MP3DP, that works very well also. I consistently get accurate prints at 80mm/sec.

Still not fast enough. So here’s my latest (printer) project.

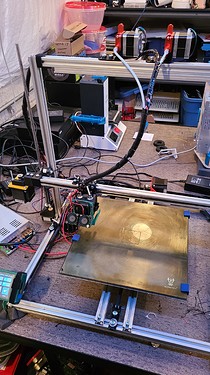

It’s pretty ugly right now since it’s already gone through a few revisions, upgrades, etc. It’s all 2020 T-slot, 310x310 heated bed, SKR 1.4 turbo with 2209s for the axes, and 8825s for the 2 extruders. The printer is based on the following design Cartesian_330X330 bed - v slots and mgn12 rail by mshonak - Thingiverse since it was the only one I could find that just used 2020 rail. I made some changes to the Y axis, again, to only use 2020 extrusion. I’m currently designing my own parts from scratch in FreeCAD to get away from anyone else’s design, plus I had to design a NEMA23 Y bracket anyway, but it will be loosely based on this one.

The big upgrades are the NEMA23 motors being used for the X and Y axes. These run exceptionally well off the 2209s that were already in place. I did have to increase the current near the max of the drivers, but they stay cool with a fan and I don’t miss any steps. I sourced these from a certain auction site for pretty cheap. $14 for 4, plus $12 shipping. So I of course had to buy 8. They have 1.26Nm(178oz/in) of holding torque and work great for what I am trying to accomplish.

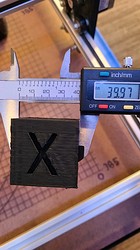

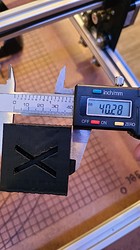

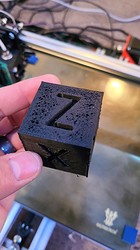

So far I’ve tuned the linear advance to .25. junction deviation is at .08. 2000mm/sec2 acceleration for all moves, 200mm/sec for non-print and infill moves. 15% for 1st layer and 80% for outside walls and top layer. Now, I really can’t tell if it’s reaching these speeds because I had originally had my junction deviation set to .01 and it seemed fast, until I changed it to .08, and it’s way faster. Simplify3D says build time is 28mins, but it took 50. Here are some video links printing a 40mm XYZ cube at .15mm layer height and 25% infill. I tried originally with .3mm layers, but the extruder kept skipping steps.

https://drive.google.com/file/d/1z5ZIFgCy2eHhB6GJ7Ur_x2ZjcAm2MolE/view?usp=sharing

https://drive.google.com/file/d/1z9R9MqYKvafuvuiOW-FJ4LgARP7jlwRQ/view?usp=sharing

The videos don’t seem to do it justice. It seems a lot faster in person.

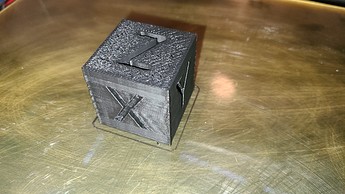

Here’s pics and dims of the finished cube.

Extruder still couldn’t keep up with the solid layers. I do have 8mm bore extruder gears on the way though ![]()

So that’s where I’m at. Just thought I’d share.