As a noob who is now trying to process all of this, I will add a few things. At the risk of beating a dead horse here but it seems like most posters more more familiar already. Please take anything in here as trying to be helpful only. Sorry for the length.

As a guitar/uke builder I am looking to grow capabilities. Precision/repeatability. Hardwood inlays with high precision, bridges (ebony/rosewood), necks (3-4" Z if possible mahogany), templates and rapid prototyping of ideas, etc. So, I want to know what this system is really capable of. Can MPCNC, do extremely precise inlays? What kid of tolerances can I expect? Is it going to be a giant pain of constant trouble? Can I upgrade to a 4" working high height? Future growth paths? Will I need separate machines for precise vs large?

I greatly appreciate those online review videos for lasers here they show actual usage and explain what is important to consider. Cut tests, line fineness, parts of the system and how to compare systems capabilities and features. In one video, you tap on what I think is a limit switch with your hand for homing. Please explain how and why. What is going on? How does a limit switch help? How does it work? How do you now where to put that switch? Is that part of the kit or an add on? Do the controller boards each support? How do they connect to the board? What else will I need to get auto-leveling working? So many questions. I would prefer more here. I love the whole beginner video series idea. I want details. I think DIY and education could be a strong spot and what helps differentiate you. I am scared to tackle with all the unknowns.

A safe path, where you have approved design(s), where you are providing part list known to work for a standard builds provide me a lot of assurance things will fit together and I wont be wasting a lot of money along the way. You kind of have this but I keep reading of things missing in the forums. Unclear to me. For me, I think a 20x30 x4"Z cutting area is about perfect for 99% of tasks for guitars and ukes and fits on a all table better then large square does. I think the recommended with options and upgrades “build the kit you want” fits the DIY model nicely. But I need help knowing what/why to choose. I might want to throw in a PI w/ v1pi and a camera combo if I knew what value it provides. Remember it cost shipping for me to order from 5 different sites and it may be cheaper to get it all in 1 place with markup with your free shipping.

Tubing … IMO the forums strongly discourage EMT to the point it seems bad/horrible. I don’t know what to expect there. Isn’t stainless like really hard to machine? Drill press, metal drilling bits, machining oil, hack saw, tube cutters, what is involved? More cost and things I may never use again. I had to read many forum posts to find wall thickness “sweet spot”. The online sellers of tubing have tolerances of 1/2" or more when cutting! Geez what is the point of ordering from them? If you could work out suppliers who would agree to some standard sizes with holes already drilled, it might solve a need IMO for those of us who would rather not deal with that part of the DIY. Or consider alternative rails easier to source. Openbuilds? IDK. Just grasping for ideas so I don’t have to do metal fab. Is that unrealistic?

QUOTE “But at that point the process stopped since I had to work out how to protect the wires, how to run the wires, find a case for the electronics, deal with jumper wires, etc. I remember agonizing about what size cable chain to purchase, having to wait for an Amazon order, designing and 3D printing brackets for the chain, finding hardware for attachment, etc”.

This is a huge fear for me. What don’t I know and ho much time and money will it cost me? I have been bitten by expensive DIY projects. Helping to educate is where I see you can provide value. The learning zone sites seem to get strong followings and grow from the good will. He YT sharers of knowledge get followings ans trusted and drive sales because of that. Craftes blindly follow and buy DIY’ers feel more comfortable starting.

IMO DIY, is all about what I feel comfortable doing. Some want to smelt, others want to assemble. We all have different backgrounds and capabilities and are only willing to go so far. Kids in STEM Robotics start easy path and learn more deeply in areas over the years. I’d love to be able to choose my own level of involvement. Education is key there too IMO.

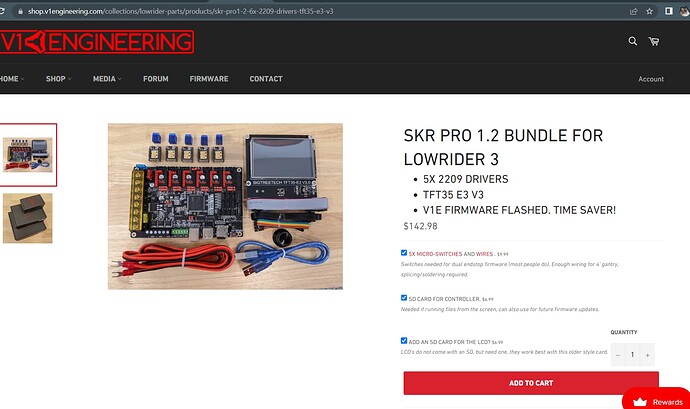

Control boards - I’ve read many forum posts and it’s still not clear at all to me the pros and cons. One is going away other cuts rough circles? I’ll pay a bit more for a high quality board with more precision we can rely on. Perceived quality is important.

Can I do an all Linux/free workflow? Can you add more details and compatibility options to the sw workflow sections? Never heard of Marlin. I don’t yet have WiFi in my faraday cage of a garage far from the house so offline options are important. Can I add a kill switch? How?

Consider some “anthropology”. Where you put a brand new user in front of your sofware/manual/website and you are only allowed to watch NOT help or communicate in any way. Where they struggle you could improve.

I try to avoid China shipments myself, long wait times, the unknown quality, recourse, tariffs, too many unknowns. Not sure I would order a China kit from you myself.

I want guard rails and safety ropes to get going quicker without risking too much cash. I like choosing the parts I want but I want to know why I am choosing them as part of the DIY learning process. I would prefer guided education path so I don’t have to piecemeal lots of info. “Help me help myself to choose your products”. Above all else, make me comfortable I know what I am doing and ordering.

Or perhaps, maybe I should shy away from DIY.

That’s my $0.02. Take it or leave it, just trying to help. Thanks for your hard work and sharing.

Cheers.