Finally finished that tape measure trick.

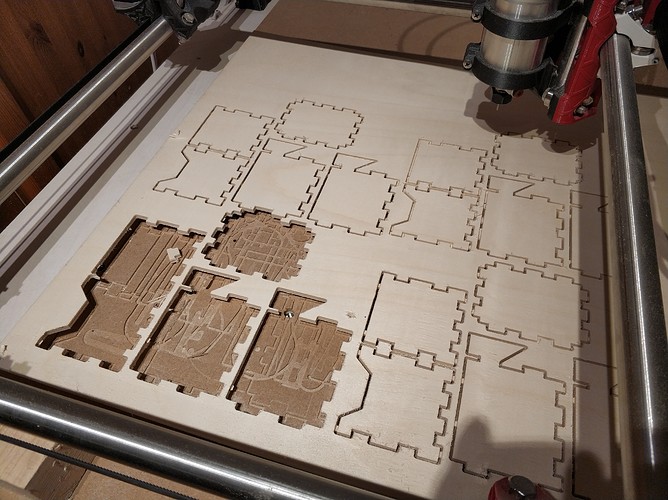

I finally had some spare time. French cleat going up.

When I am done with a few more different boxes I will create a thread in the “Things you have made” section and make the plans available for everyone.

Oooh, nice concept! Now you’re giving me ideas

Nice French cleat implementation. I like the tabbed boxes on them.

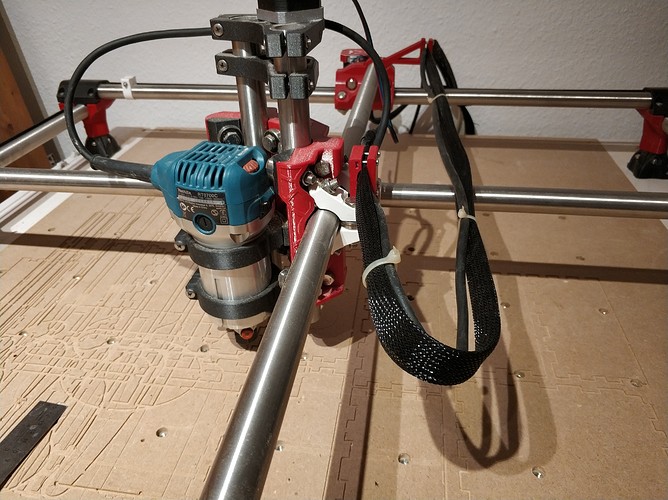

It’s been a little over a year now, and Schneewittchen has been used a lot. One of the best things that I ever did was to build her. I learned about 3D printers, electronics, mechanics, and first and foremost a lot about CAD and CAM.

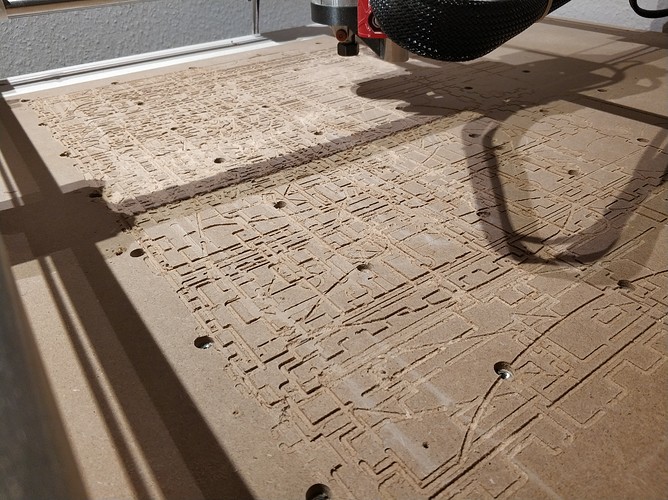

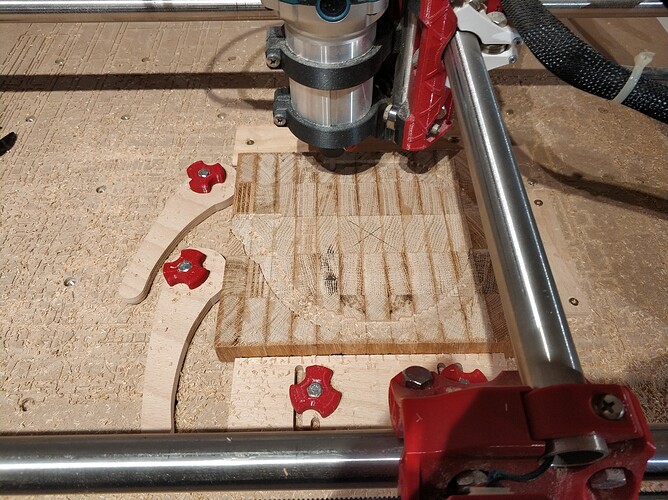

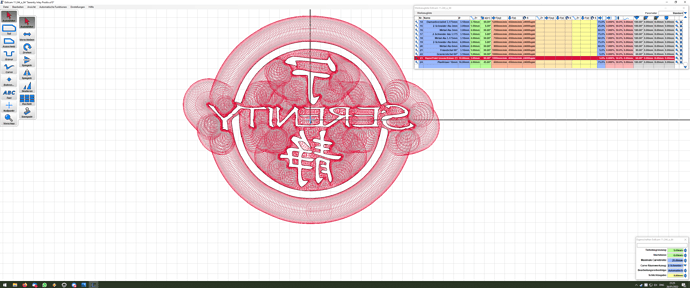

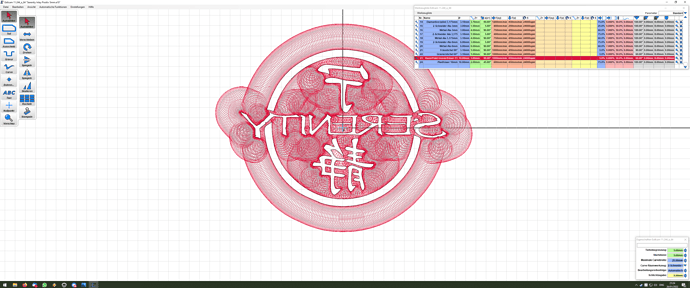

First real inlay work. I hope it is going to work. WIP pictures:

Who can guess what it is going to be?

A circle!

“Take my love, take my land, take me where I cannot stand. I don’t care, I’m still free! You can’t take the sky from me…”

@RobP I created the “normal” inlay first, you can see it further up. If I now cut out where it is supposed to go it won’t fit.

I therefore ran the program a second time with 5mm as a starting depth (if I had just run it a second time by just setting 0 5mm lower, it would have destroyed the first cut since Z travel height is only 3mm). It then takes of 5mm more, so it will fit a dephts of 5mm. Sometimes it cuts through 10mm of material, but never with the whole endmill, so that was okay.

This is the cut in the board, 5mm deep, so for the inlay to fit it has to be double the depth.

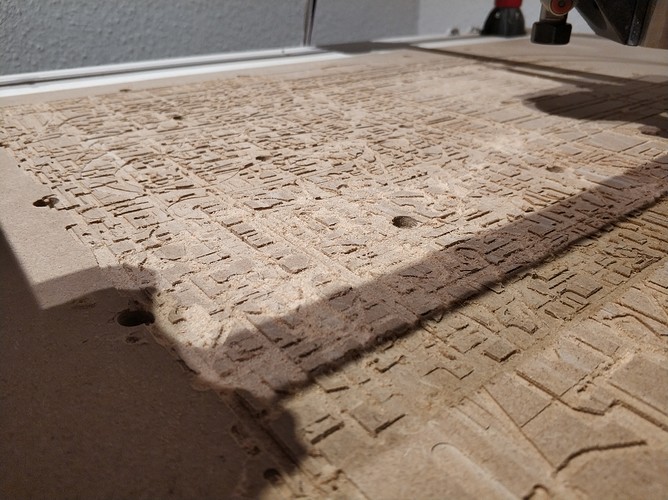

One thing I did not consider was the tip of the 60° endmill: it left some material standing in the one on the left below (there was also some in the big circles, I ran the program for those a second time with automatic depth limiting). I marked some (former) problems with red circles.

I manually removed some of those with a chisel, but it would have just been better to leave the depth of the engraving bit to auto anyway, because none of the cuts is wider than 10mm, so it cuts the pockets deeper and would get rid of my problems. I don’t think it would make the glueup more unstable.

I hope this was more clear now.

Aha, so youre doing a full 3D carve, not “faking” it with a 2D tool path and offsets. That makes a lot more sense and now I see why the process is relatively simple.

Nah, it is actually 2D, with a V-Bit (Sorotec Online-Shop - VHM-Gravierfräser). It’s just the one highlighted in the pictures (and a 6mm to clear some stuff).

What I mean is you are doing a “carve” operation and not “part” or “hole” (or pocket or island). That tool path moves in 3 dimensions and cuts with variable depth.

The complicated (what I call 2D) approach uses a constant depth with “part” or “hole” operations and then you have to do all sorts of calculations and offsets to trick Estlcam into producing the correct output, and sharp corners are not even possible.

Oh, I understand now: it’s a carve.

It did not work out as well as I expected. It seems shallow, wide Inlays are more easy. For the very filigrane letters it wasn’t deep enough with the 60° endmill. I now ordered a 30° and will be trying it again. The cuts should be a lot deeper then.

I put glue and oak dust into the cracks, hoping it will look at least decent. It was only my second inlay, I flew to close to the engine of a firefly and got burned.