Ttttttttouchplate. Woop.

Does the ‘Ttttttttt…’ stand for the sound of the milling tool in the lower left corner?

Chattermarks are my trademark!

Things I learned: If Ryan says “It needs a light touch…” it does not need what I understand as a light touch. My girl was always rattling, today I tightened the screws on the trucks. No more rattling. I think his light touch aims towards auto mechanics.

And somehow the whole CNC makes weird noises when cutting some corners. Might have been the same thing. Will see that tomorrow. Getting there at least. I am as well fiddling with the rpm, yesterday 24k were fine for hardwood, today it produced an ear shattering whining. Dunno what happened there… -_-

Send pix.

Do you drive rather a french or italian car or a swedish one?

looks nice! What kind of aloy you are using? AW 5083, AW 6082 or prob. AW 7075?

I bought this: https://www.ebay.de/itm/Kg-2-99-Aluminium-10-Kg-Reste-Reststücke-Platten-Block-Zuschnitte-Vierkant/252276903441, it’s AlMg4,5Mn, not the best for milling but okay. Did it without coolant.

This page has got a good overview over the different kinds of aluminium: https://www.cnc-step.de/alu-fraesen/ (it’s German though, but I know you are also).

I prefer the EN notation AW5083. For a touchplate fine. Generally “very” weak but of course for the MPCNC no problem. I typically use AW 7075 - also called (german: Flugzeugaluminium) - high tensile aluminium! You can also machine it with the MPCNC but need to be very carefully. I like to work with that kind of aloy e.g. created some parts for my motorbikes etc.

For things like a strut to keep a rear caliper bracket from spinning around the axle I’ve used 6061 T6 with good results, easier machining than the 7075 and takes a nice polish for cosmetic parts.

Not cleaned up, roughly 7x7cm. Wood was warped a little so writing isn’t brilliant at the top. Meh. Wanted to try how precisely the MPCNC can work. Boy does it deliver. It turned out pretty well, gave it to someone from that school as a present to show what a self-build CNC can do.

Kudos. What was the workflow, what kind of data is it based on, and how did you process them?

BTW, what a young school! My old learn-shop was established in 1320. And 60 kilometers away, there is a high school that can look back at even 11 years more - an all gapless history of teaching and learning.

Good enough to be honoured by means of today’s most advanced high class tool - an MPCNC!

Tadaaaa!

Thanks. I took the school’s logo, traced it with Inkscape, saved it as an dxf, added a border and basically only used the carve outside function of estlcam for the logo and carve inside for the rest. Then I hit start and waited for an hour.

I have built a new braking system for my Suzuki GSX 1100 Katana. The 2 brake caliper adapters for the front I have realized with Alu but had to be out of AW 7075 because of the force. Breaking with ca. 250 km/h means the adapters need to handle round about 11.500 N.

I have physically/mathematically calculated the whole breaking system for german TÜV (no problem!) and also realized it.

Other AW 7075 parts are engine mountings, mountings for cockpit etc.

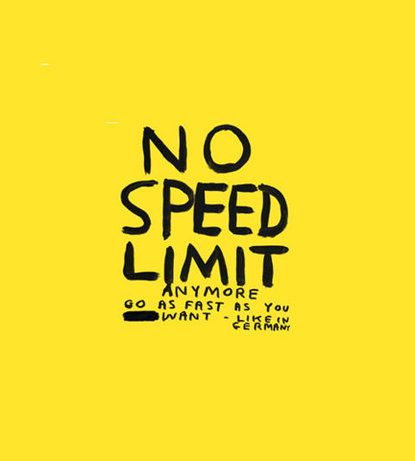

Braking from 250km/hr in the states often means handcuffs and ‘awards’ from local government agents. ![]()

Except when it’s labeled Exhibit A. ![]()

In that case, postpone the braking to a safe area.

Can someone tell me why I have such a whining sound? Video here:

https://www.kreutzercloud.de/s/yJts3SCrgB64RJg (might take a minute to load, sorry.)

I had to tighten a few bolts on the core that hold the Z Axis. Before my cuts were very slightly off but at least it was silent. Now it makes that sound. My ears. Ugh.

Noone knows.

I just went on a shopping spree on Sorotec. I really needed that 6mm Alu Bit. -_-

Hm… Not sure. If the plywood didn’t look clamped down so well, one could think, it could create such a sound (in the video I couldn’t make out, if the chips were “dancing” on your plywood board).

Sure, that none of you parts cracked, when you tightened those bolts?

And: Is your endmill ok, or is one of the cutting edges or corners damaged?

Did you try to feel (with your hands / by touching) where the vibrations were coming from(being careful, of course  )?

)?