Great meeting Vicious1 at MRRF. So glad I brought my MPCNC. It generated a lot of attention!

You’re in Australia!!! ???

I just figured they must have held MRRF at the International Space Station this year. I was kind of jealous…

I was really surprised to see a mpcnc at the festival. The seeme guys wanted me to bring mine last year, but it wouldn’t fit in my car.

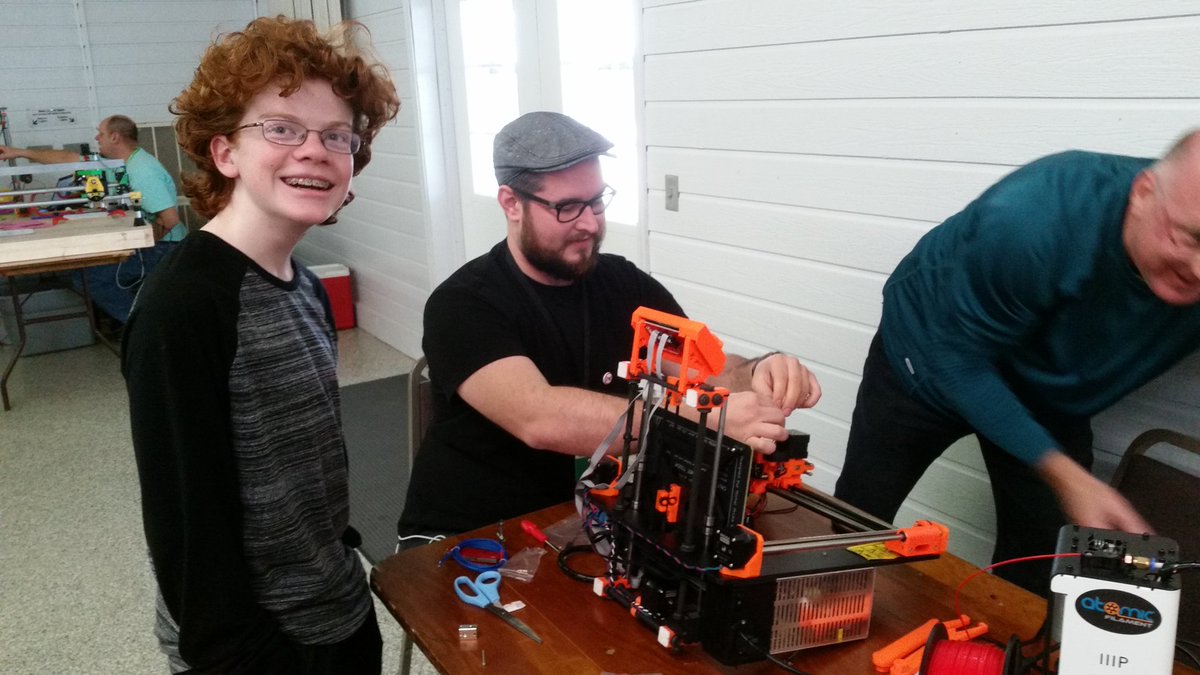

I feel so short! Awesome pic, I think I had that look on my face the whole day. Got a mountain of emails and some orders to fill then I will see What pics I remembered to take. I hope I can go next year and bring some toys with me. Ron I’m sorry we didn’t get to chat more but the buzz you created by bringing the MPCNC was so awesome, the questions and feedback.

I really did not know if bringing it was a great idea. The MPCNC fits so well into the Reprap movement I thought it was a good fit, but it was not a 3d printer so was not sure if I should.

As it stands, I was amazed at how much interest it generated! I hardly had any time to go and look at the show myself.

Some saw that you were a sponsor and just assumed I was the guy who invented it. LOL. It was great I could just point in your direction and say “It’s his fault”.

You can see us all nerding out over in the corner.

https://lanoc.org/review/editorials/7479-midwest-reprap-festival

I was so bummed, I got to talk with so many people, but I still feel like I missed out. I went back in on Sunday and a lot of people were gone or packing up to leave. It was a small event but I still feel like I missed a bunch and I was there a little over 12 hours I think on Saturday. My body just gave out at about 10:30. Said goodbye to Barry and passed out as soon as my head hit the pillow. Woke up and my voice was shot, I felt like I had diarrea of the mouth Saturday, so excited I couldn’t shut up.

So I only took 5 pics While I was there…dammit. Too excited.

I guess I signed up too late to get the logo on the poster.

Early morning MP3DP’s (walked in the door and saw the printers in less than 3 minutes, I was ecstatic!)

Late afternoon MP3DP’s (I don’t remember your name buddy jump in and remind me please)

Ron’s MPCNC, and cnc cut delta.

Did anyone see this thing? This is awesome.

I was watching it for a while, I kept thinking “man they better hope stratasys doesn’t catch them” but it looks like it doesn’t violate the patent. Good way to ramp up production, or print long things, They really should have been printing the chain mentioned in there to prove its strengths. I had to walk by and check it out a few times to understand what was really going on.

Barry pointed this one out to me, https://flex3drive.com/flex3drive/, something I had also never seen. The website doesn’t really show it well but it is a “direct drive” extruder with the drive motor connected by a flex shaft. So all the benefits of a direct drive with the moving mass of a bowden.

Berd air was the undercover star of the show, http://www.themakerhive.com/shop/viewitem.php?productid=45, tons of printers were running it or a diy version of it I bought a nozzle for $5, they were sold out of the pumps.

So many things there.

Oh, I understand that flex3drive now. I didn’t really understand it when someone mentioned it before. That will be really useful with multiple extruders, and of course, doesn’t have the flex filament problems bowdens have.

I wonder if that air pump would be good enough for the laser air pump. You’d want a different nozzle, obviously.

I would just love to have a big queue of parts ready to print, and have the printer just churning them out. Things like which parts need support, and whatnot would change though. It’s probably not that realistic to have it printing for a week without any human intervention though. Things break. The tuning would be tougher though. It would be easy to get the first line printed level, but you’d also have to have the angle just right, so that 1" away from the “contact point” you’d be exactly 1" above the platform, or you’d get squished layers.

I didn’t think of that, bed angle tuning would replace leveling…thought to test I would imagine, you would actually have to let it print for a long time to see if your adjustments were right. Get it tuned though and man I would be able to get out an extra part or two. I am near my printers all day but sometimes it is hard to tell when one is done when the other 6 are still running. Maybe I should just rig up the belt drive and just not tell statasys.

The berd air comes with the round nozzle and a straight one, the straight might work for a laser but I would guess you might want a little more power. Pure speculation though. Or…maybe the laser thing doesn’t need too much air just a really focused little nozzle would do the trick. Hopefully I can try it out soon.

Man, so many ideas. The berd air thing makes me want to to run out and get a cheap o airbrush pump.

The flex thing is cool, but angles could be an issue. If youve ever used a felx coupler on a ratchet you’d know what I’m talking about.

I’ve been thinking about a dual x with the motor on the top x and a really short Bowden tube. And with the bed air thing you could reduce yhe weight on the hot end x even further.

What you should really do is just have the filament coming out of a tube, and have a freakin’ laser beam pointed at it to melt it. Don’t even bother with a nozzle :). Should be no friction, so the bowden problems will go away.

You could figure out a new printer geometry, so the nozzle always stays in the same place, so you don’t have to move the laser, but then, of course, what’s the point of reducing the weight. You could also have the laser dance around with the printer “head”, and that would be cool, but of course, if you could do that, you might as well sell it as a home security feature instead.

What you really should do is set up a lot of lasers, pointing at every possible location of the filament, so that no matter where it is, there’s at least one laser pointing at it.

after looking over the flex3 drive again on my home computer and finding some videos, I’m on board. At least I like the idea now. But it’s quite expensive for a few gears drive shaft and printed parts. Then you’d still need an e3d v6. Putting it at about 170 dollar upgrade.

https://www.lowes.com/pd/Dremel-Rotary-Flex-Shaft/999972892

This might beable to be modified to work.

They’ve modified it to have less backlash than a dremel flex shaft.