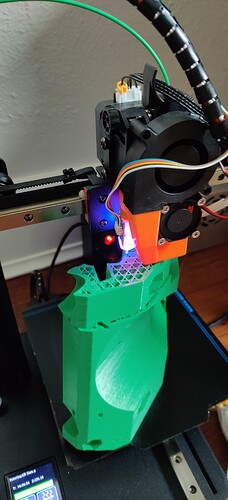

Looks like something caught and shifted the bed. Do you think super glue is enough or should I use a couple screws when I cut this off and reattach it?

Gluing plastic can be very unreliable.

Use an activator spray if you try super glue, if ABS was used you could try to glue it with acetone but I am afraid a full reprint should be the only viable option…

Sorry to see that my primo had a issue with the trucks like that 4 at once.

Layer shift can have various causes.

-

part slips due to bed adhesion failure. Consider using hair spray to prep a clean bed. Excellent.

-

grub screws loose on (one or more) coupler(s) driving gear(s) for belt(s). Check and tighten. Consider adding thread locker. Good idea to add.

-

print head catches hard on part of print that’s sticking up, gets held until steps are skipped, has no way to correct. Can be a result of leaky loose nozzle dropping chunks of molten plastic onto print. Check nozzle connection to hot end. Fix by cleaning and tightening.

The last one could be related to the second one if loose grub screws on Z lead screw allowed a skipped step in Z, causing head to catch on print and loose steps in X and / or Y axes.

There may be other causes I’m not thinking of.

I’m not confident on reliability of a glued part here.

Cutting this apart to glue it has its own set of challenges. Friction during cutting heats the part, which softens and deforms it.

It was the last one. I have a magnetic bed and it was rotated. The bottom was a little warped and raising up, which was lifting the bed and not holding as strong as it normally would. Not sure why the extruder hit the part, though.