It’s been a pretty fun project. I think the most frustrating part was removing the linear rails multiple times because I kept forgetting to install the 3 bolts first, but other than that, it’s really been a pretty straightforward process.

A couple things I’m pointing out here for other newbies to this.

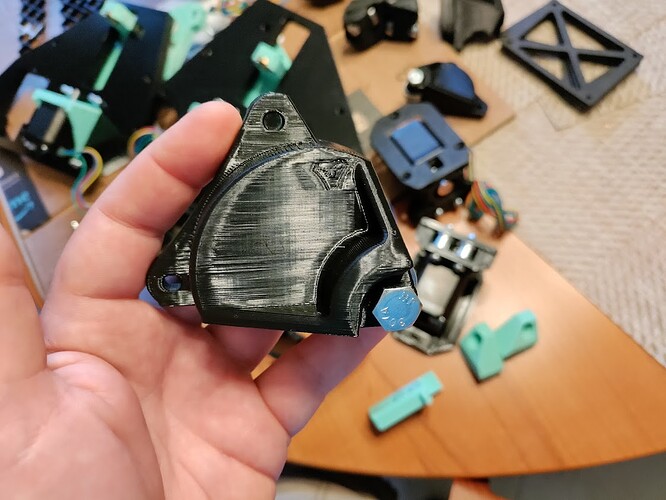

- It’s worth buying the 3D printed parts if you are in a rush to assemble. I didn’t and wasn’t in a rush, and to me it was awesome to put my Anycubic Vyper to work making something functional. However, I kept feeling like I couldn’t print fast enough. I kept making sub-assemblies at night and would be sad, when I had to stop. really fun project!

– I used Overture Black PLA for the majority of the parts and Hatchbox Mint PETG to accent a bit

– I used PrusaSlicer. 0.8mm nozzle. 3 perimeters, 0.28mm layer height, 0.9mm extrusion width, recommended infill for each part. Had really nice detail, but still printed pretty fast overall. With my settings I averaged 70mm/s speed, but typically 40-50% of that for external perimeters. - I had to drill out the holes for most of the bolt holes so they would freely slide in. The tolerances for those were a little too tight for me. Best to check your parts before assembling so if you need to bore them out a hair, you can do it in one batch and reduce time and cleanup.

- Check your XZ plates if printing to make sure they are proper dimensions and the stub is perpendicular to the plate. I originally printed in PETG for the XZ plate. One was a little wonky and the leadscrew didn’t align with the stub nut. Not sure if it just printed skewed, it got dropped, or what, but was not working. The one lead screw was not aligned with the motor coupler. If printing these, stick with PLA per the documented recommended settings. I reprinted and all was good.

- If you can solder, I recommend soldering your end stop wires to the switches. fast and easy enough and durable. I made sure to cut my end stop wiring to exact lengths. This was necessary for me to eliminate the risk of a taped dupont connectors coming loose. I was shifting some things around before I cut my final struts and while it was still taped, I managed to shake it loose juuust enough that when I went to home Y, I had an open circuit on the one side and had to emergency stop the machine because it was pulling to one side and off of the y rail. My recommendation, solder your endstops, and just cut your wire to the exact or slightly longer length you need to terminate directly to the main board. (I don’t have this issue with my stepper motor wiring. Those I just taped together in the event I need to replace a motor, it’s not too much effort to replace)

- Definitely Label your wires. Makes reconnecting a breeze. Also take pictures of your wiring so you have a reference

- wire loom, while unnecessary, really polishes up the build. I used 1/4" braided PET loom for the stepper motors and endstop wiring, and then used 3/8" spiral wrap over 2 1/4" braids on each side. makes the wired stiffer there and looks tough.

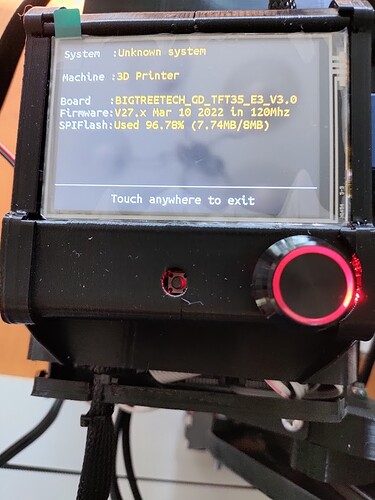

- [EDIT 2022/07/11] a little velcro works great for holding the screen secure to the base but still easy enough to remove

- Thanks @jamiek for the parametric struts! That tool works great for it! first time I used openSCAD and was super simple to make the adjustments for the width of my gantry and the number of brackets

- Thanks @jeffeb3 for pointing me to DougJoseph 's updated image for the board wiring

- And last but not least, thanks @vicious1 for all your hard work putting these designs together and giving me the ability to make!

Some Pics

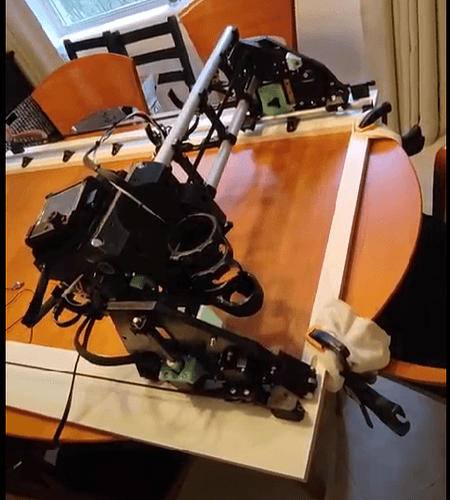

Almost ready to test print, but need to square the frame since it’s too hot to mount to the tablesaw table outside

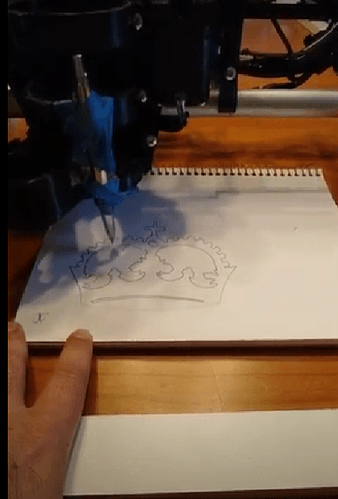

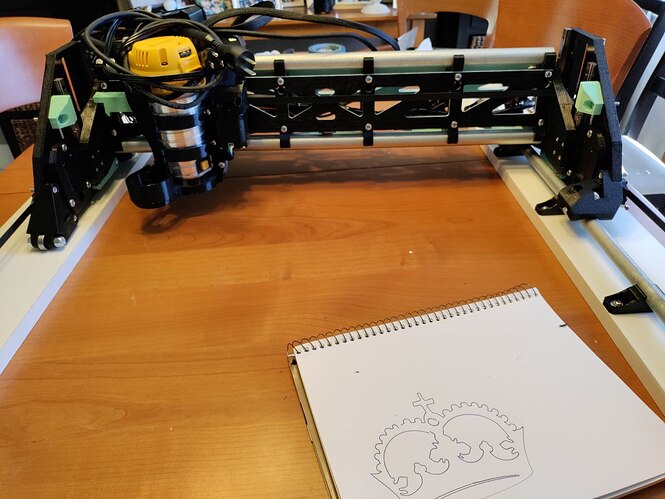

Test frame attached to do pen crown tests before moving to bench outside

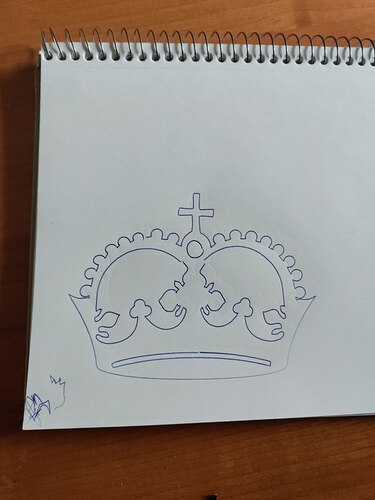

Crown came out good considering my poor attachment of the pen. I did another time with pen zip tied tight in the vacuum area of the mount instead and the crown came out perfect.

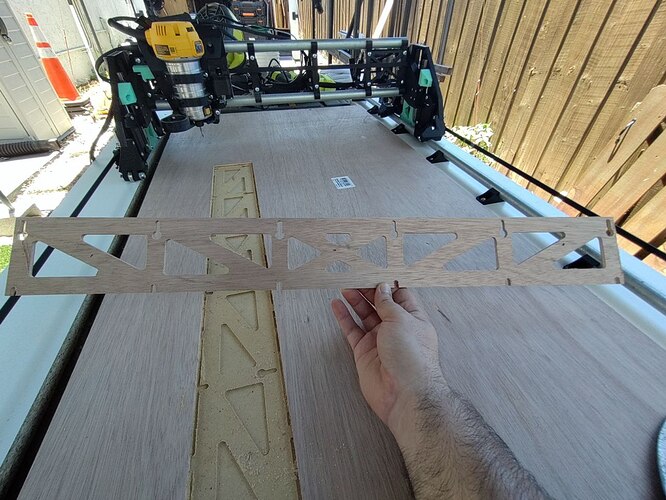

I learned a lot on the first cut. I used 3/16" luan board for the struts since hardboard was out of stock locally. At first I did 3 passes (2mm per pass) and cut too much (total of 6 mm and only 2mm of tabs. just barely over 4 I was already through the board so there were no tabs. I rectified this while it was cutting by popping in a couple finish nails to hold it in place. this was easy since I cut all the interior pockets first and could easily see where I could pop a nail in without it getting in the way of anything. for the 2nd and 3rd, I updated the job to do 2 passes of 2.5mm depth per pass and holding tabs 2.5mm high and that came out perfect. Used all default speeds, cut time for parts 2&3 came out to about 35mins ea. Also check your clearance settings in ESTLCAM. I only had 2mm clearance and my spoil board was a hair prouder on the far Y, so there were 2 little scrape drags at the end of my first cut. I wasn’t going to try and surface my whole spoilboard just for that so I just raised my clearance to 3mm and that was enough to stay clear of the workpiece in the final areas. I’ll make sure to surface my spoilboard flat so it’ll be perfectly parallel to my gantry now that I’m fully built, but for someone new to CNC this is something that i just didn’t quite understand until I started cutting.

The best part about a CNC… repeatability!

All reassembled, finalized wiring and tested motors and end stop homing. All finished, just waiting on my vacuum tube to come in so I can permanently attach a small tube like in the original photos to quick connect to the shop vac.