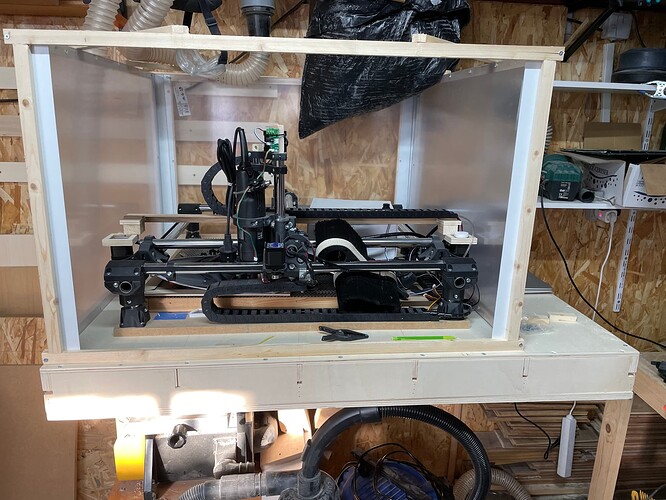

One more step to a decent setup!

When i finished my built of the primo, I had made myself a control box in a cardboard box reinforced with MDF.

I made it in a hurry in about 2 hours and it did the job but it was cumbersome and not safe enough IMO.

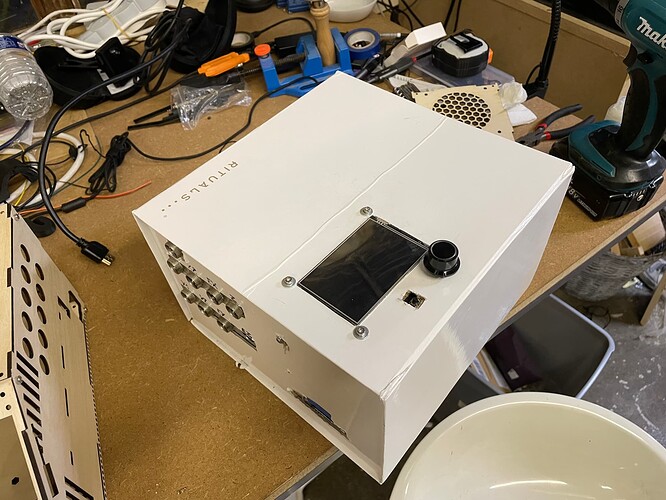

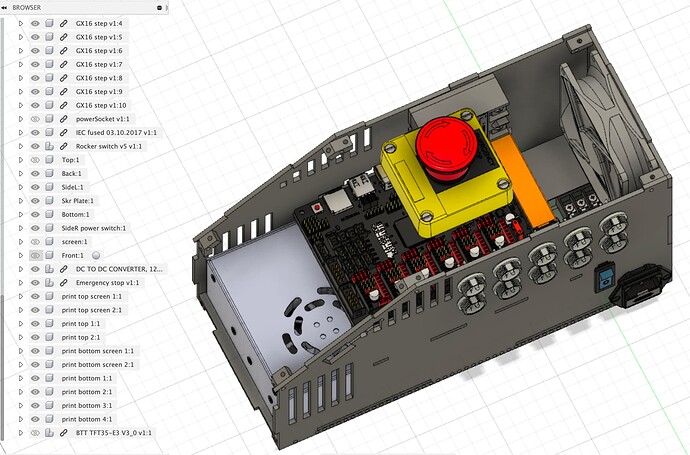

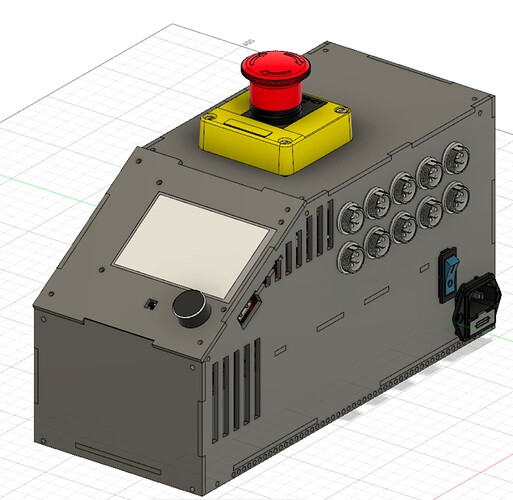

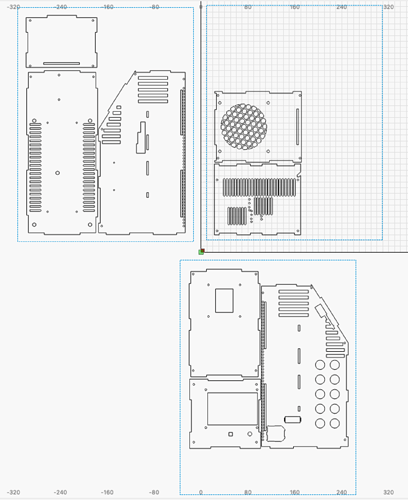

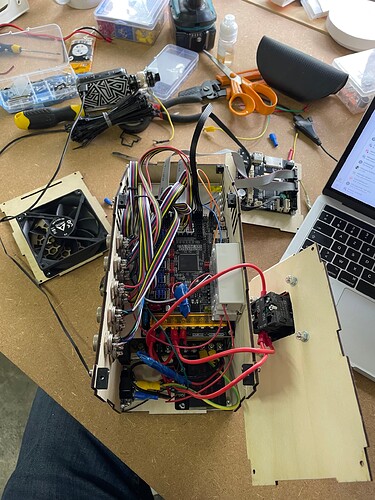

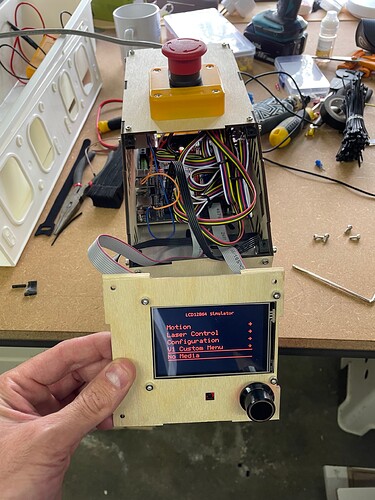

I didn’t want to stay on a temporary solution that lasts forever so I designed from scratch/sketch, a control box under Fusion360 with all the improvements I wanted (eStop, unique 24V power supply, 24V to 12V/10A converter for 12V Neje …) and I laid this flat in DXF for LightBurn.

All electronic components, plugs and switch were found on GrabCad, corresponding on what i’ll use.

I didn’t wanted to 3D print a box as it take ages and Mesh alteration was a burden to adapted it to my needs.

Just a few “false nut” pieces were made in 3D printing to hold it all together with M3 screws(can be seen on 1st Fusion picture)

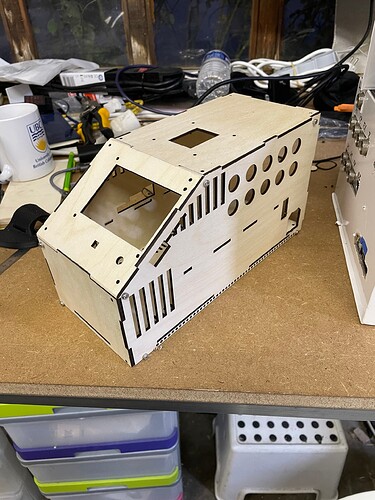

I laser burned the whole thing out of 3mm plywood, a bit less of 3 hours to cut everything( i used a conservative slow 100mm/min speed at 100% to ensure every cut would pop out) and dry assembly was perfect, no laser Kerf issue !

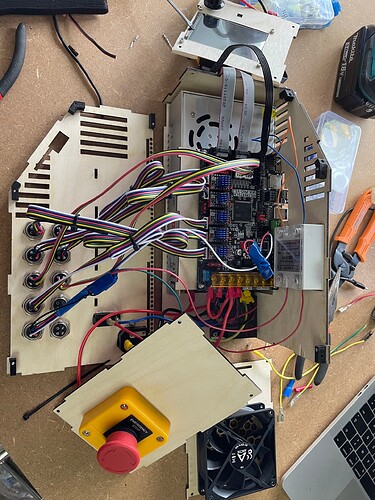

And the filling of the box with all the components was perfect too !

I had to postprocess by triming/sanding the top and bottom sides of the screen panel to get correct angles as laser only do perpendicular cuts.

There is still some imperfections like aviation plugs labels i forgot to engrave or too large usb/sdcard slots but i will deal with it.

Only my motor wiring that are too long and messy, not great for drivers ventilation so I plan to shorten them and crimp them again in JST one day or another…

About the eStop i didn’t plugged it directly on the 220V power supply but in interruption of 24V lines because when I shut off the power supply some built in capacitors make the SKR board, motors and lasers still powered on for ~2 to 3 seconds, anoying in case of emergency…

I use the red switch for turning off power supply.

It’s the first “serious” project i design and build on and for my (still just) Laser Primo - rabbit orders from my wife it’s nice but it’s fine 5 minutes  - and i’m quite glad of the result so I wanted to share it with you in my MPCNC log.

- and i’m quite glad of the result so I wanted to share it with you in my MPCNC log.

A long post ! I hope not TLDR, more pics than text thus

- and i’m quite glad of the result so I wanted to share it with you in my MPCNC log.

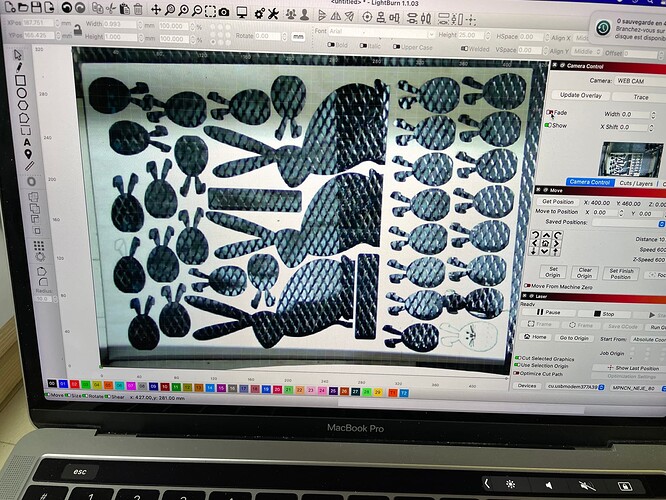

- and i’m quite glad of the result so I wanted to share it with you in my MPCNC log. Hopefully it happened right after I finished cutting a batch of Christmas presents

Hopefully it happened right after I finished cutting a batch of Christmas presents But 2022 has passed long live 2023 !

But 2022 has passed long live 2023 !